Optical corrective spectacles component without center shifting during quick assembly

A technology of optical correction and glasses components, which is applied in glasses/safety glasses, glasses/goggles, optics, etc., can solve the problems of high cost and long cycle, and achieve the effect of small diameter, wide coverage and reduced prism effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

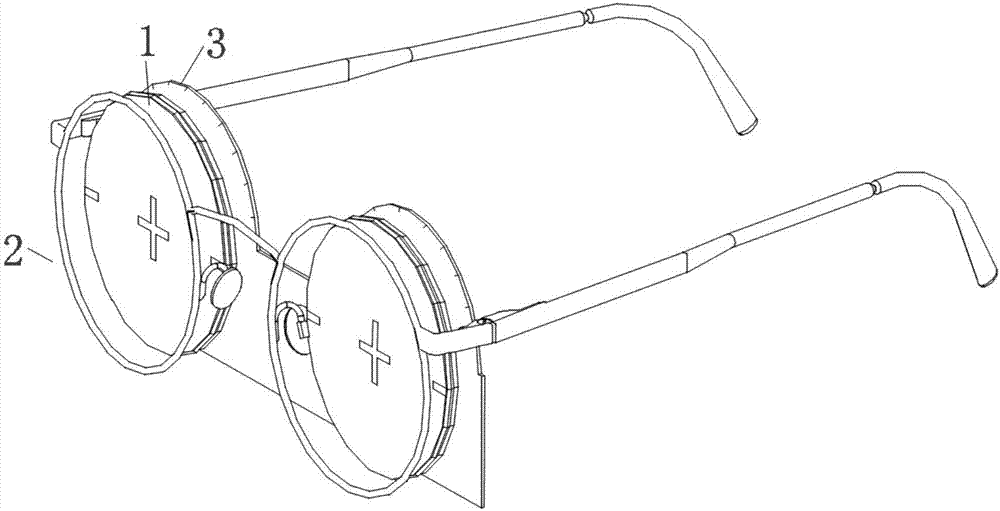

[0025] Such as figure 1 , figure 2 As shown, a quick-assembled optical corrective eyeglass assembly is characterized in that it includes a circular lens 1 with a prescription, a frame 2 matching the circular lens 1, and a combined scale plate 3. The lens 1 preferably has a diameter of 25 mm to 59 mm. The mirror ring of the mirror frame 2 is circular, and the distance between the centers of the mirror rings is 52 mm to 74 mm. In order to facilitate comparison of angles, the diameter of the circular lens 1 is greater than the diameter of the horizontal axis scale 32, and the size of the center points of the two circles ranges from 52 to 74, with an increment of 1 mm, and 23 sizes of a certain diameter are produced. series of frames.

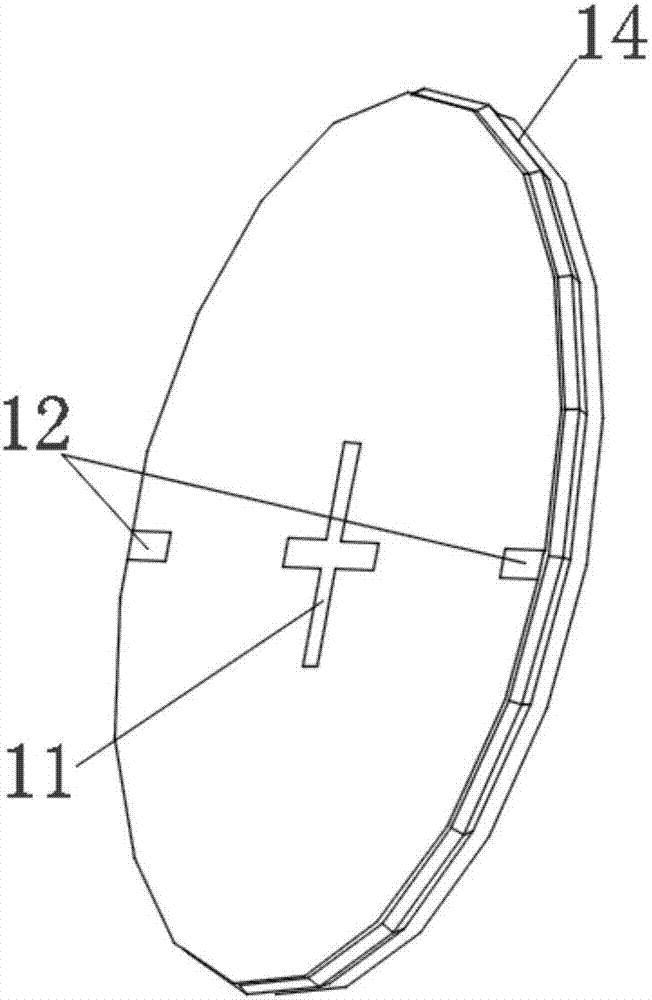

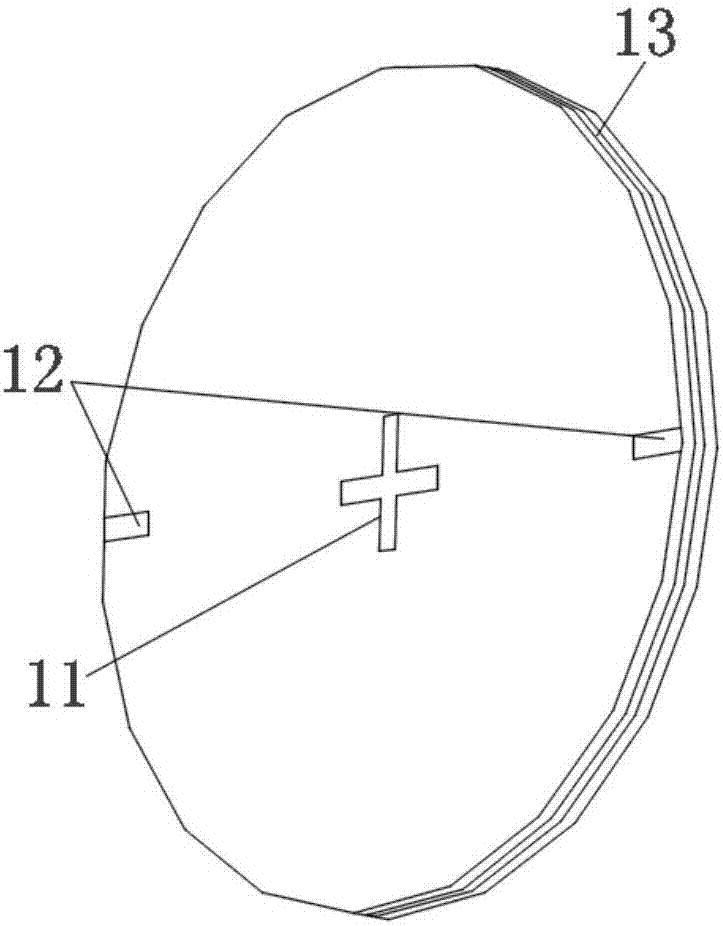

[0026] Such as image 3 , Figure 4 As shown, the outer surface of the lens is provided with a circle of sharp edges 13 or inwardly rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com