Motor vehicle real vehicle wiper test system and test method

A test system and test method technology, applied in the field of wiper test devices, can solve the problems of no wiper wiping frequency, incomplete testing, and inability to make a complete evaluation of the overall performance of the wiper, so as to achieve complete measurement performance and improve test accuracy. The effect of high precision and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

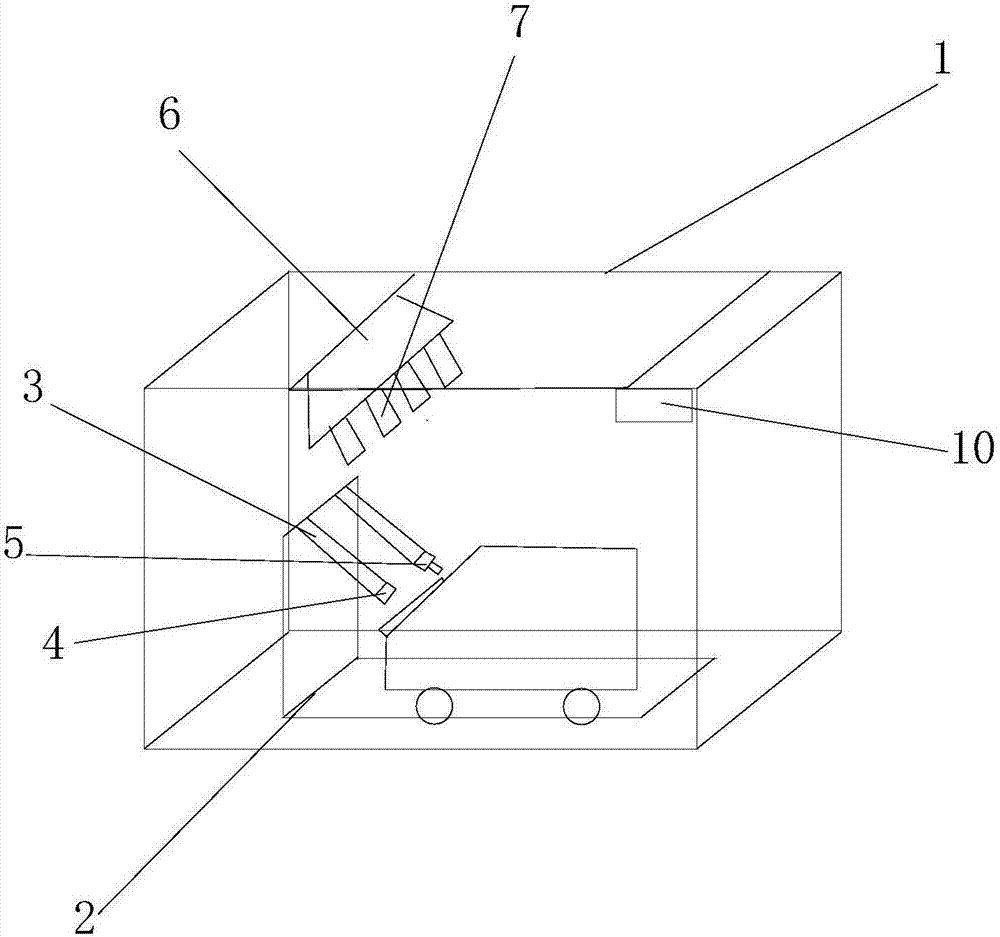

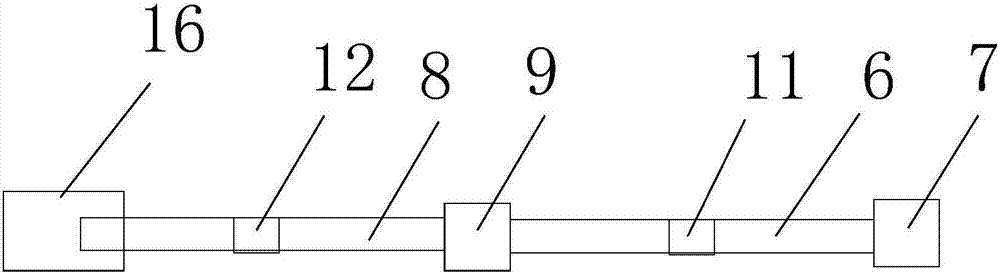

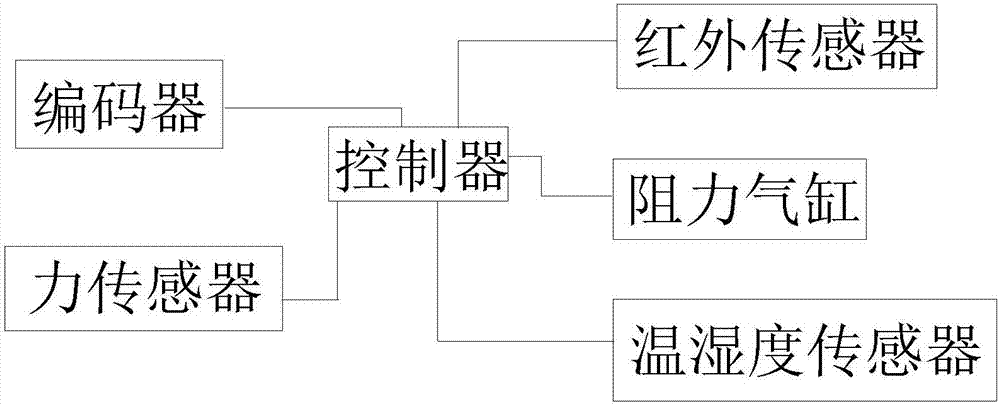

[0023] Such as figure 1 The real vehicle wiper test system for a motor vehicle shown includes a spray room 1, and a transport frame 2 for placing a motor vehicle is arranged in the spray room 1, and the bottom of the transport frame 2 is provided with a driving transport frame 2 to be transported to The conveying mechanism inside the spray room 1, the conveying mechanism can be a cylinder, a screw module, etc., a support 3 is fixed on the transport frame 2, and an infrared light towards the windshield 15 of the motor vehicle is fixed on the support 3. The sensor 4 and the resistance cylinder 5, the wiper bar 13 on the windshield 15 of the motor vehicle will pass through the infrared sensor 4 and the resistance cylinder 5 successively during the movement process, and also includes a controller, the controller and the infrared sensor 4 respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com