Combined sealing device for quick-opening alcohol extraction kettle

A combination of sealing and extraction kettle technology, which is applied in engine sealing, liquid solution solvent extraction, mechanical equipment, etc., can solve the problems of high creep, easy aging deformation, and limited use of metal C-rings, etc., to improve the sealing effect , the effect of meeting the sealing and leak detection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

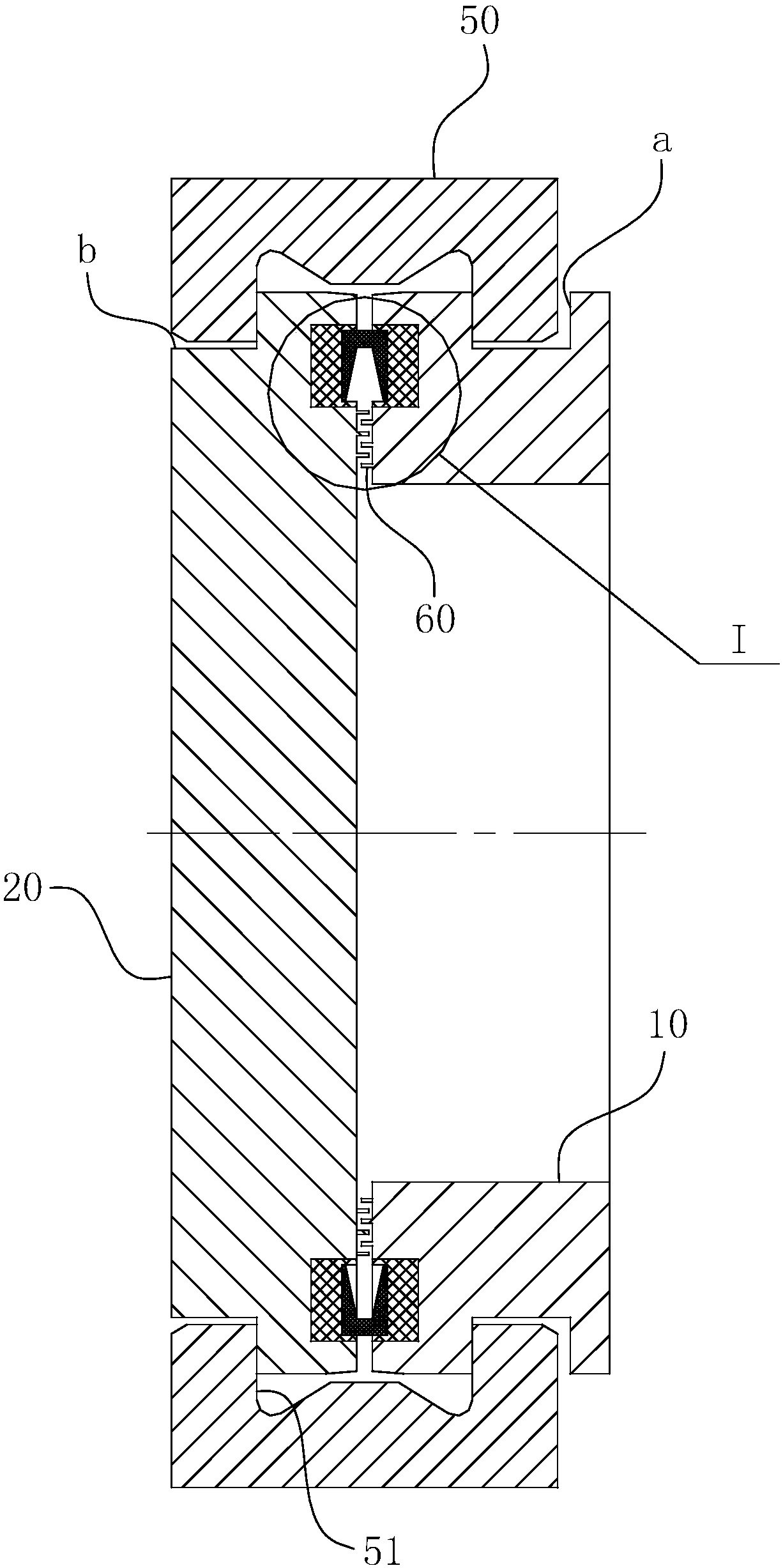

[0028] The concrete implementation structure of the present invention refers to Figure 1-3 As shown, it includes a cover plate 20 on the end face of the sealing end seat 10 at the feed port of the alcohol extractor. The clamp 50 is clamped between the cover plate 20 and the sealing end seat 10, and the clamp 50 is operated by an external quick-opening device, so as to realize the layer-by-layer transmission effect of locking force.

[0029] Such as Figure 1-2 As shown, a settling groove is recessed on the adjacent surface of the sealing end seat 10 and the cover plate 20, and a ring-shaped heat-insulating heat-insulating seal is fitted in the two sets of matching settling grooves with an interference fit. Seal seat. In actual operation, heat the heat-insulating sealing seat to 330°C and then heat-insert it in the corresponding placement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com