Machine liquid composite transmission system based on pressure control

A compound transmission and pressure control technology, applied in transmission, fluid transmission, mechanical equipment, etc., can solve problems such as high cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

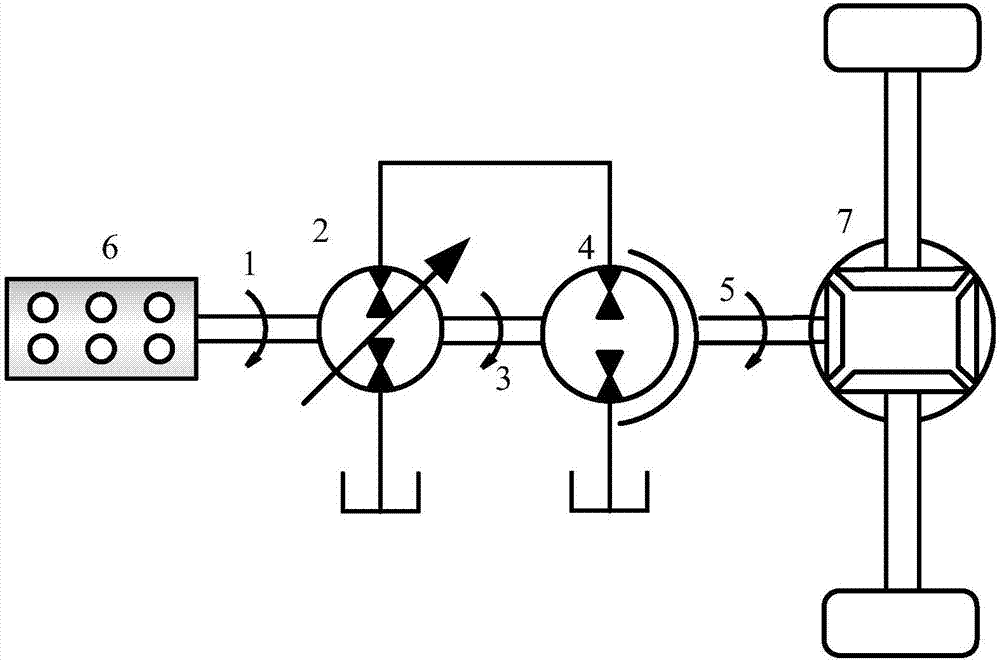

[0040] Figure 4 It is another application example of the present invention, and the present invention is applied in the fan cooling system of construction machinery. Wherein the input shaft is connected with the diesel engine 6, and the output shaft is connected with the engineering machinery cooling fan 8. When construction machinery is working, it is necessary to adjust the speed of the cooling fan in real time according to different working conditions. When the working condition is light, the variable pump / motor unit can work in the motor mode. When the working conditions are severe, the variable pump / motor unit can be operated in the pump mode, and the actual speed of the fan can be adjusted in real time according to the required speed to realize the speed-up of the fan blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com