Torque motor actuator of linear diesel engine

A torque motor and diesel engine technology, applied in the field of marine diesel engine position-controlled electronic speed-regulating actuators, can solve the problems of low reliability, limited rotation angle, poor linearity of the rotation angle sensor, etc., and achieve the effect of fast response and reliable control.

Inactive Publication Date: 2010-12-01

HARBIN ENG UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its disadvantages are: the reliability of single-winding coil and single sensor is low; the linearity of the rotation angle sensor is poor; the sensor has no gap elimination mechanism; the motion conversion mechanism is complicated, which reduces the response speed and control accuracy of the device

However, since the torque motor cannot reliably limit the rotation angle, cannot realize linear motion and cannot directly feedback the rack displacement of the fuel injection pump of the diesel engine, an additional mechanism must be designed to ensure the reliable and safe use of the torque motor as a diesel engine speed control actuator.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

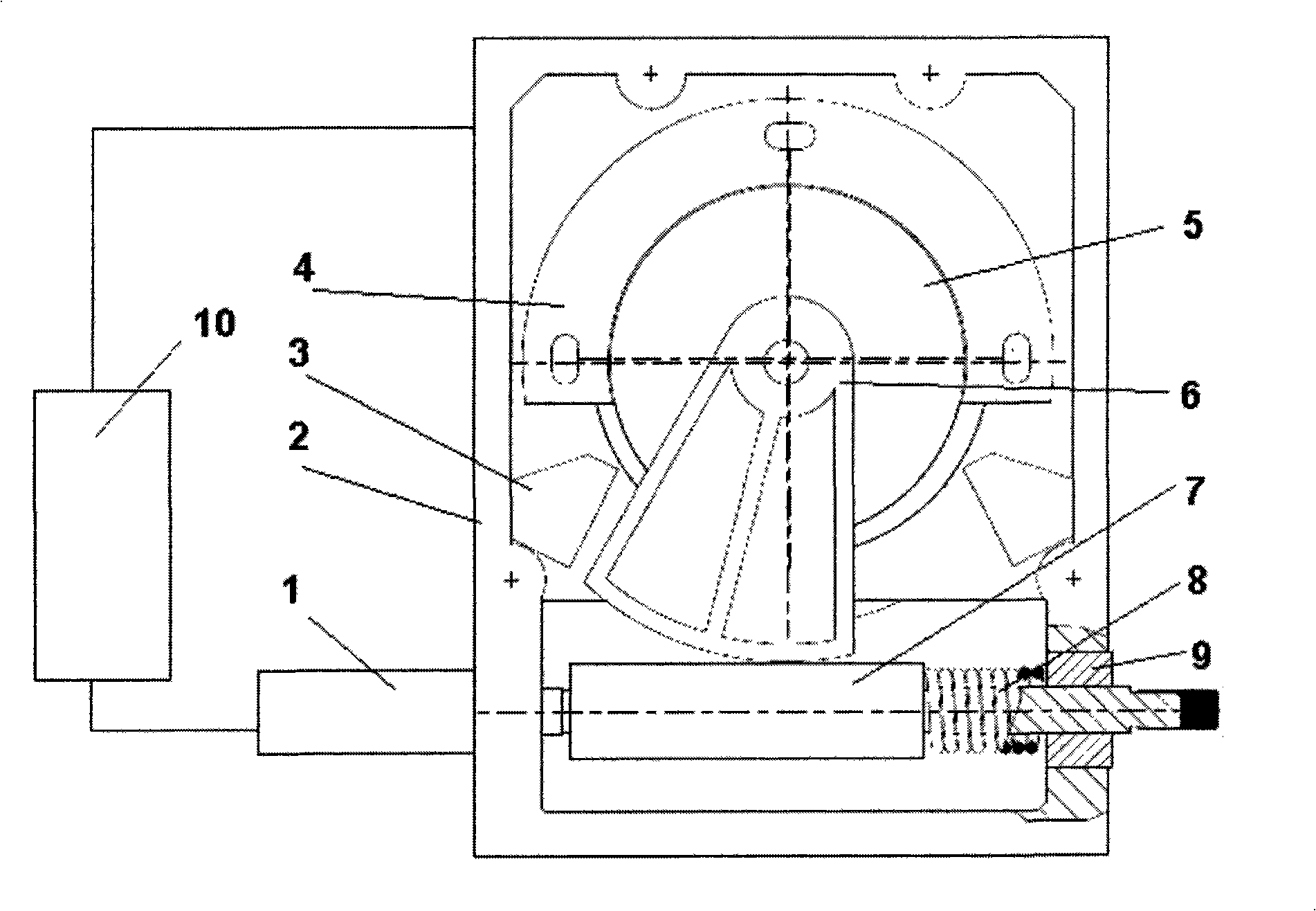

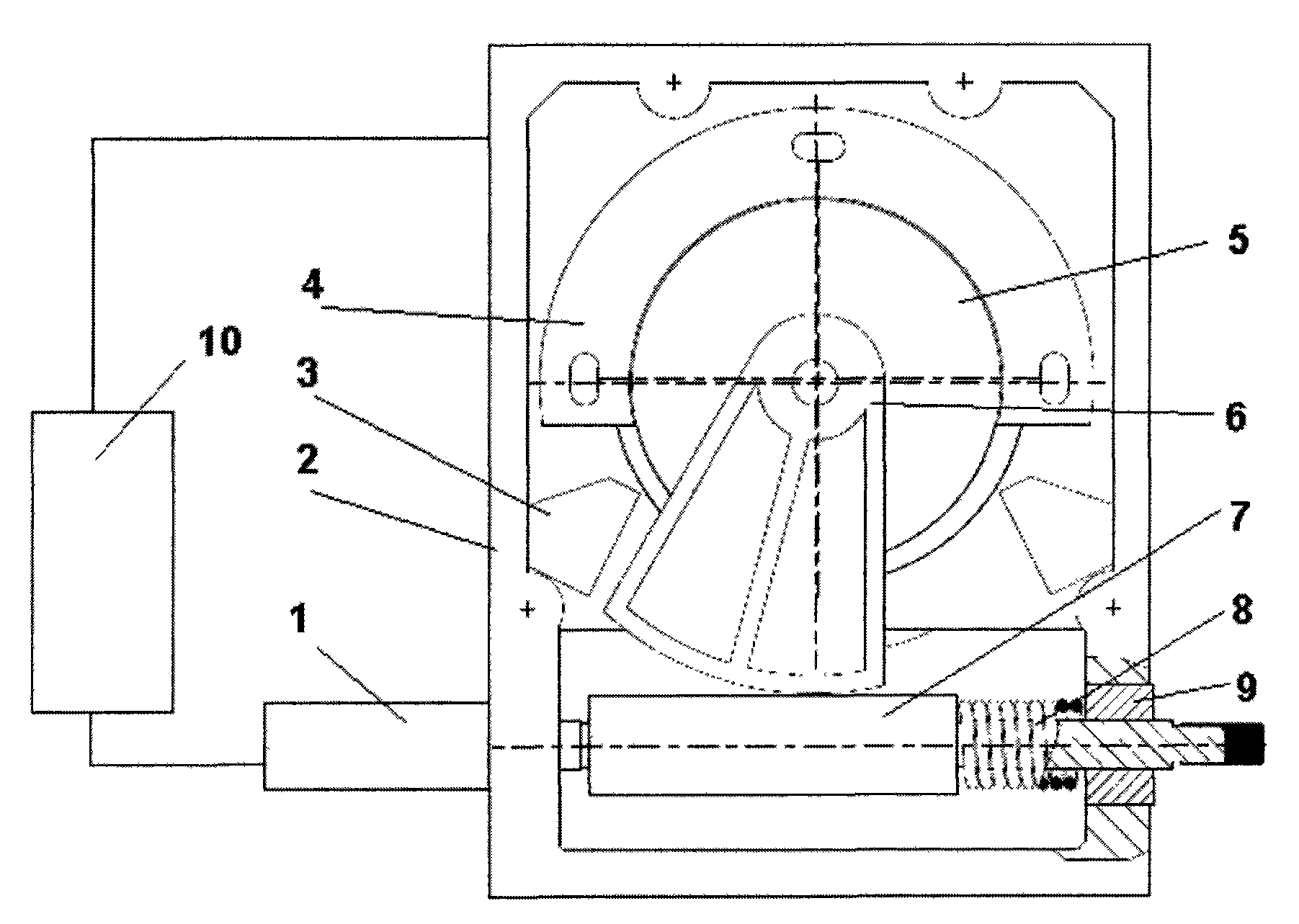

The invention provides a torque motor actuator of a linear diesel engine, comprising a torque motor, a displacement sensor, a stroke control locating iron, a shell, a controller, and the like, whereinThe invention provides a torque motor actuator of a linear diesel engine, comprising a torque motor, a displacement sensor, a stroke control locating iron, a shell, a controller, and the like, wherein the torque motor is mounted on an eccentric wheel which is adjusted and fastened in the shell, and a segment gear is mounted on the torque motor; a rack shaft is mounted on the shell by two linear bethe torque motor is mounted on an eccentric wheel which is adjusted and fastened in the shell, and a segment gear is mounted on the torque motor; a rack shaft is mounted on the shell by two linear bearings, and a spring is mounted at one end of the rack shaft; a displacement sensor is mounted at one terminal of the rack shaft, is connected with the controller and feeds offset of the rack shaft baarings, and a spring is mounted at one end of the rack shaft; a displacement sensor is mounted at one terminal of the rack shaft, is connected with the controller and feeds offset of the rack shaft back to the controller, and the output of the controller controls the torque motor. The torque motor actuator of the linear diesel engine can reliably control the rotating speed of the diesel engine, hack to the controller, and the output of the controller controls the torque motor. The torque motor actuator of the linear diesel engine can reliably control the rotating speed of the diesel engine, has higher response speed and is suitable for controlling the rotating speeds of middle-powder or small-powder diesel engines.s higher response speed and is suitable for controlling the rotating speeds of middle-powder or small-powder diesel engines.

Description

A Linear Diesel Engine Torque Motor Actuator (1) Technical field The invention relates to a speed-regulating actuator for a diesel engine, in particular to a position-controlled electronic speed-regulating actuator for a marine diesel engine. (2) Background technology At present, the position-controlled electronic speed control actuators of diesel engines used on ships in our country basically use proportional electromagnets, torque motors or electro-hydraulic actuators as the moving elements of the actuators, which are respectively used for small, medium and high-power diesel engine speeds. control. As an electronic speed control actuator, the proportional electromagnet can only realize two-way movement by adding a return spring, so part of its output force is used to overcome the tension of the return spring, which affects its output force. As a moving element of an actuator, a torque motor can only achieve rotational motion, and a conversion mechanism is required to ob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02D11/10

Inventor 石勇姚崇马修真宋恩哲费红姿

Owner HARBIN ENG UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com