Automatic torsion adjusting system

A technology of automatic adjustment and torque adjustment, applied in the field of machinery, can solve problems such as insufficient torque of the motor, and achieve the effect of avoiding burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

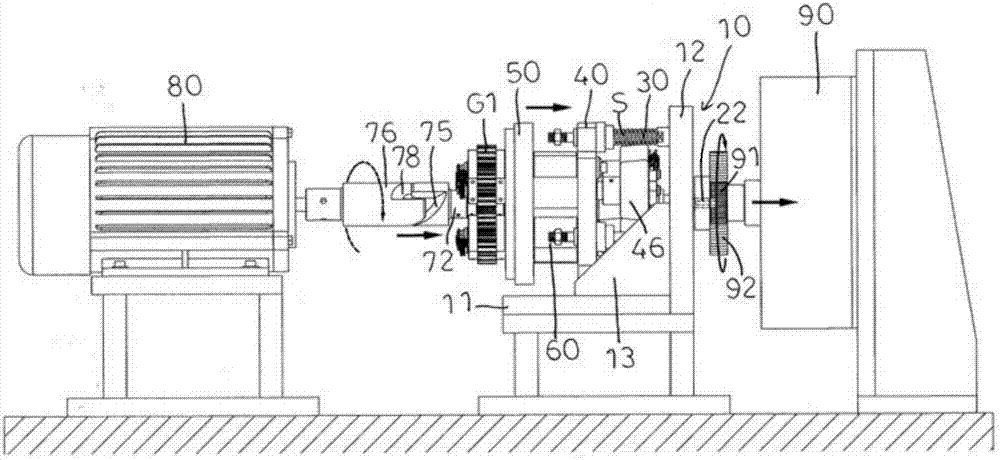

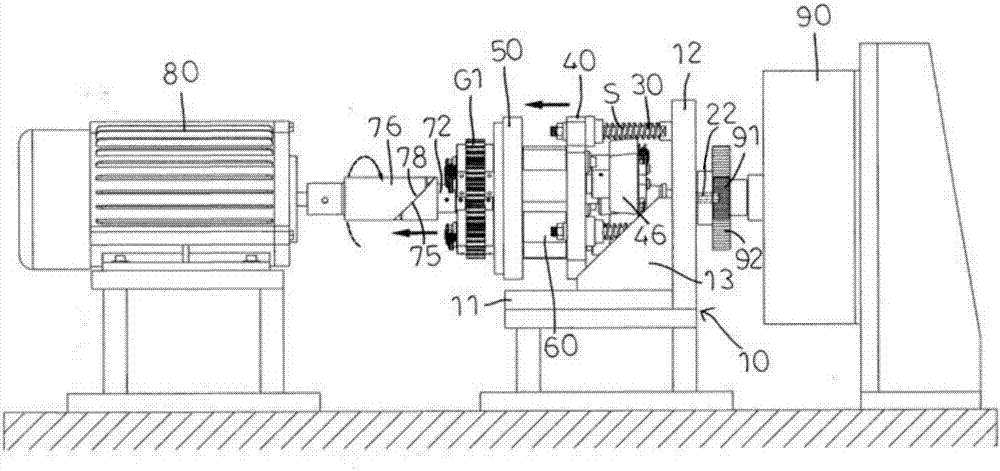

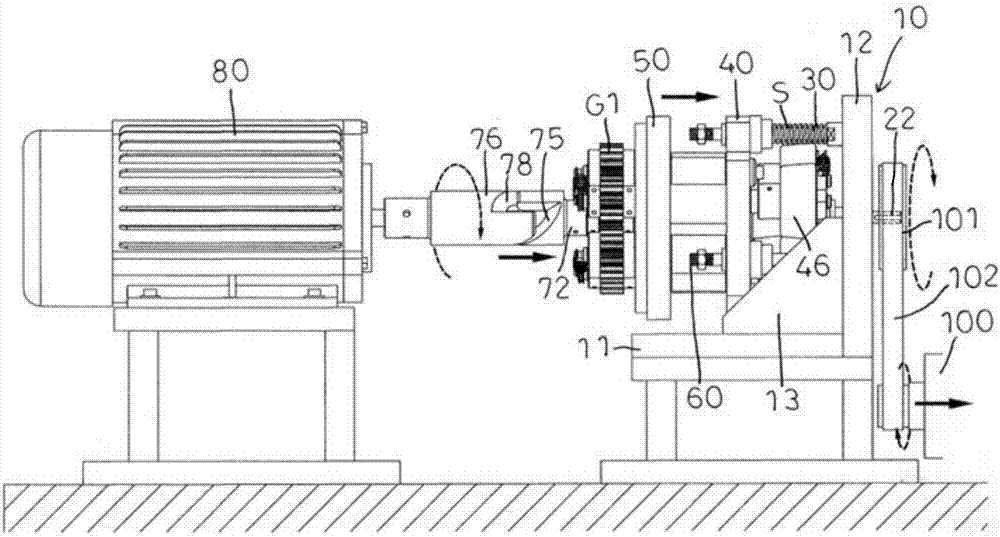

[0098] The present invention provides an automatic torque adjustment and amplification system, which includes: a seat body, an output shaft, three positioning rods, a first disc body, a second disc body, three cams, three sets of swinging parts and an input shaft, wherein:

[0099] The seat body is L-shaped, including two parts, a horizontal panel and a vertical panel. A shaft hole is made in the center of the vertical panel, and a bearing is installed in the shaft hole, which can pass through and fix the output shaft, and the output shaft is fixed by a buckle. Fixing, the seat body is made with 3 equally divided screw holes on the circumference of the vertical panel surrounding the periphery of the shaft hole, which are used as fixing 3 positioning rods.

[0100] The middle position of the output shaft is made with a conical surface with a wide front and a narrow rear. The two ends of the output shaft are the output end and the coupling end. at the center of a plate;

[0101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com