Double-layer pipe for gas supply of gas engine

A gas engine, double-layer tube technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of affecting the safety of the engine room, time-consuming and labor-intensive, and large workload, and achieve easy maintenance and replacement in the later period. Substantial features, strong effects of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

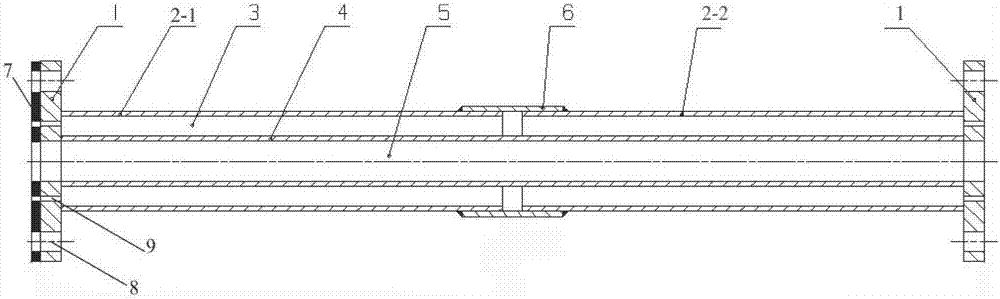

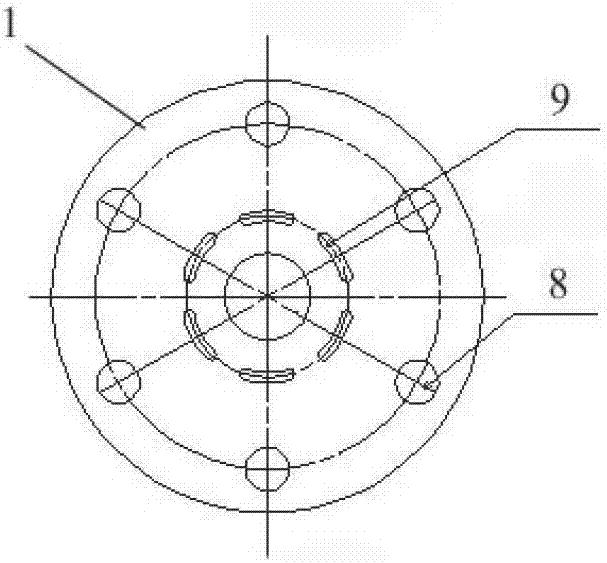

[0020] Such as Figure 1~2 As shown, a double-layer pipe for gas supply to a gas engine includes an inner pipe 4 and an outer pipe 2; it also includes a mounting flange 1, and ventilation holes are distributed between the center circle of the mounting flange 1 and the bolt hole 8 9. The inner tube 4, the outer tube 2 and the mounting flange 1 are made of metal materials. The inner layer pipe 4 is distributed inside the outer layer pipe 2, that is, a gas passage 5 and a ventilation passage 3 are formed; the outer layer pipe 2 is divided into a left section 2-1 and a right section 2-2, and the outer section The outer port of the left section 2-1 of the layer pipe 2 is combined with the left port of the inner layer pipe 4 on one of the mounting flanges 1, and at the same time, the outer port of the right section 2-2 of the outer layer pipe 2 The port and the right port of the inner tube 4 are also combined to the other mounting flange 1; the ventilation holes 9 are distributed b...

specific Embodiment 2

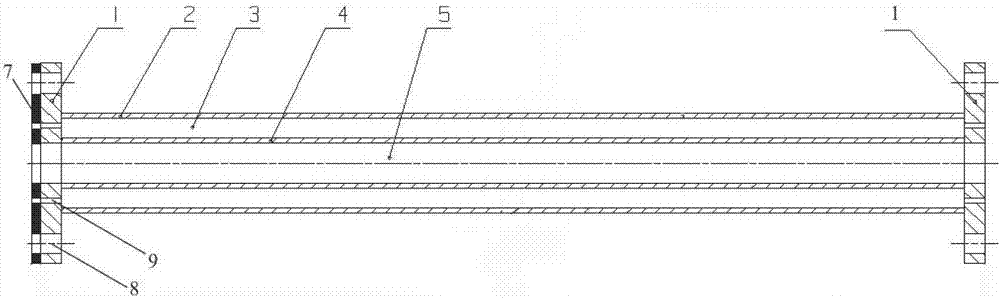

[0022] Such as Figure 3-4 As shown, the difference between this specific embodiment and the above-mentioned specific embodiment 1 is that the outer tube 2 is not segmented, and the length is equivalent to that of the inner tube 4, and the outer diameter of the inner tube 4 is set to match The diameter of the center circle of the mounting flange 1 is welded by inserting the inner tube 4 into the center circle of the mounting flange 1. Of course, the port edge of the inner tube 4 cannot exceed The end face of the mounting flange 1 is used to facilitate the connection of the mounting flange. With this solution, the sleeve 6 can also be omitted. This specific embodiment has a simpler structure and a higher degree of safety.

specific Embodiment 3

[0024] The difference between this specific embodiment and the above specific embodiment 2 is that this specific embodiment adopts 3D printing technology to integrally print the inner layer tube 4, the outer layer tube 2 and the installation flange 1, so , and its constituent materials are not limited to metallic materials, but can also be other non-metallic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com