A new type of annular braided mesh and its manufacturing method

A technology of circular weaving and manufacturing method, which is applied in the field of woven mesh, and can solve the problems of increasing the tensile strength and increasing the wear area of the mesh surface, so as to achieve improved tensile strength, strong anti-folding ability, increased warp and weft density and line coverage density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

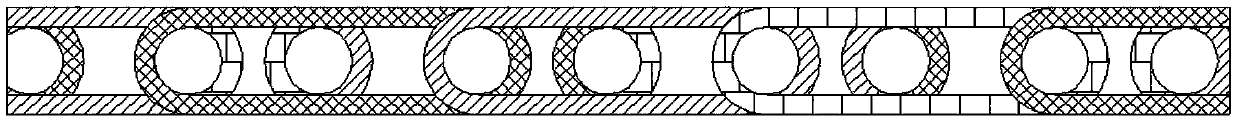

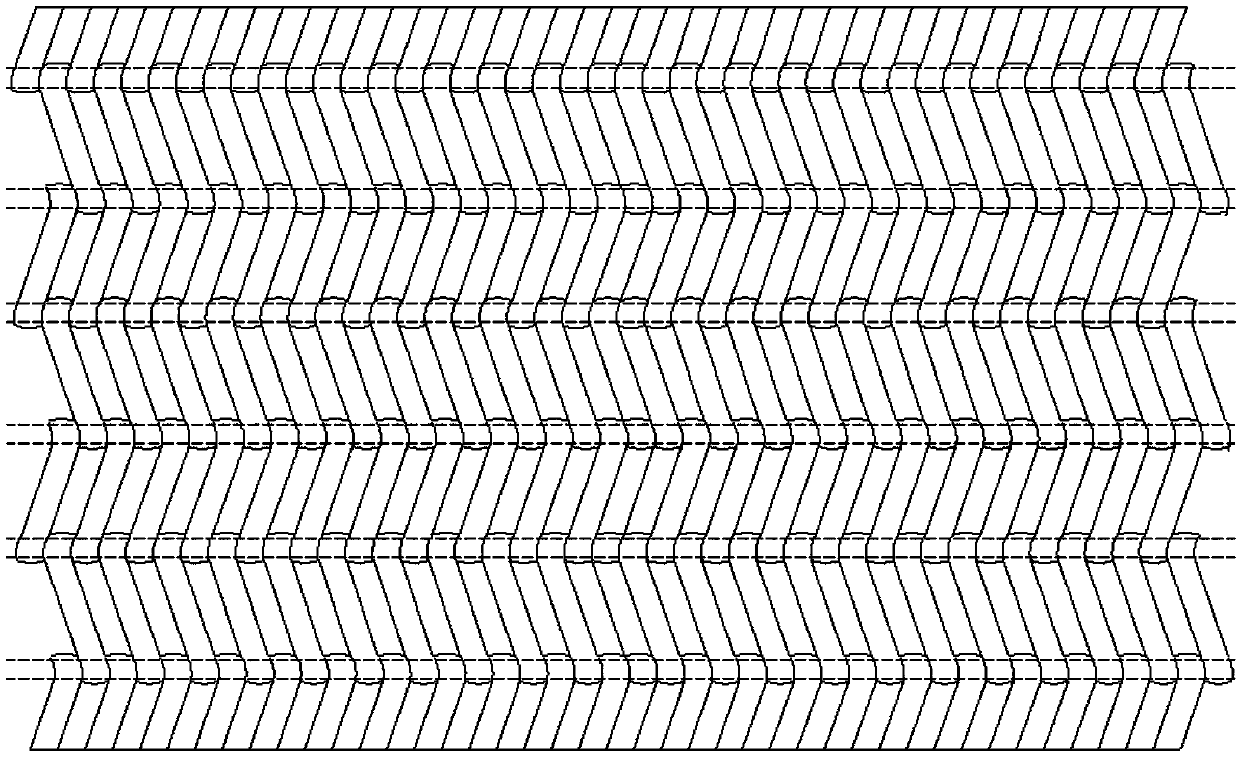

[0031] Such as Figure 1-2 As shown, a new type of circular braided mesh, the circular braided mesh adopts a circular structure wound by a circular monofilament, when splicing, a circular structure with a different direction is embedded in two circular structures with the same direction, and then in the A circular monofilament acting as a hinge shaft is inserted into the common tubular pores formed by the intersecting circular structures to form a circular braided structure.

[0032] Its manufacture method of endless braided net, comprises the following steps:

[0033] (1) Take the PET round monofilament with a wire diameter error of less than 1% and a diameter of 0.90mm, and wind it at a temperature of 165°C to form two types of circular structures, namely the same circular structure and different directions Circular structure; wherein, the control precision of the major axis and minor axis parameters of the inner diameter of the circular structure is below 1%;

[0034] (2)...

Embodiment 2

[0039] A new type of circular braided mesh, which adopts a special-shaped structure wound by a special-shaped monofilament. When splicing, one isotropic structure is embedded in two isotropic structures, and then formed after the isotropic structures intersect. A special-shaped monofilament that acts as a hinge shaft is inserted into the public tubular pores of the slab to form a circular braided structure.

[0040] Its manufacture method of endless braided net, comprises the following steps:

[0041] (1) Take the PET special-shaped monofilament with a wire diameter error of less than 1% and 0.55mm*0.90mm, and wind it at a temperature of 130°C to form two kinds of winding special-shaped structures, namely isotropic structure and anisotropic structure Structure; among them, the control accuracy of the long axis and short axis parameters of the special-shaped structure inner diameter is below 1%;

[0042] (2) First splicing two homeotropic structures together; then taking one a...

Embodiment 3

[0048] A new type of circular braided mesh, which adopts a special-shaped structure wound by a special-shaped monofilament. When splicing, one isotropic structure is embedded in two isotropic structures, and then formed after the isotropic structures intersect. A special-shaped monofilament that acts as a hinge shaft is inserted into the public tubular pores of the slab to form a circular braided structure.

[0049] Its manufacture method of endless braided net, comprises the following steps:

[0050](1) Take the PA 612 special-shaped monofilament with a wire diameter error of less than 1% and 0.55mm*0.90mm, and wind it at a temperature of 170°C to form two kinds of special-shaped structures, namely, isotropic structure and anisotropic structure Special-shaped structure; wherein, the control accuracy of the long axis and short axis parameters of the special-shaped structure's inner diameter is below 1%;

[0051] (2) First splicing two homeotropic structures together; then tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com