Automatic swing and stirring foaming device

A stirring and foaming, automatic technology, applied in the field of foaming aluminum foaming, can solve the problems of vortex formation, uneven distribution of gas bubbles, increase of foaming chambers, etc., and achieve the effect of uniform distribution of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

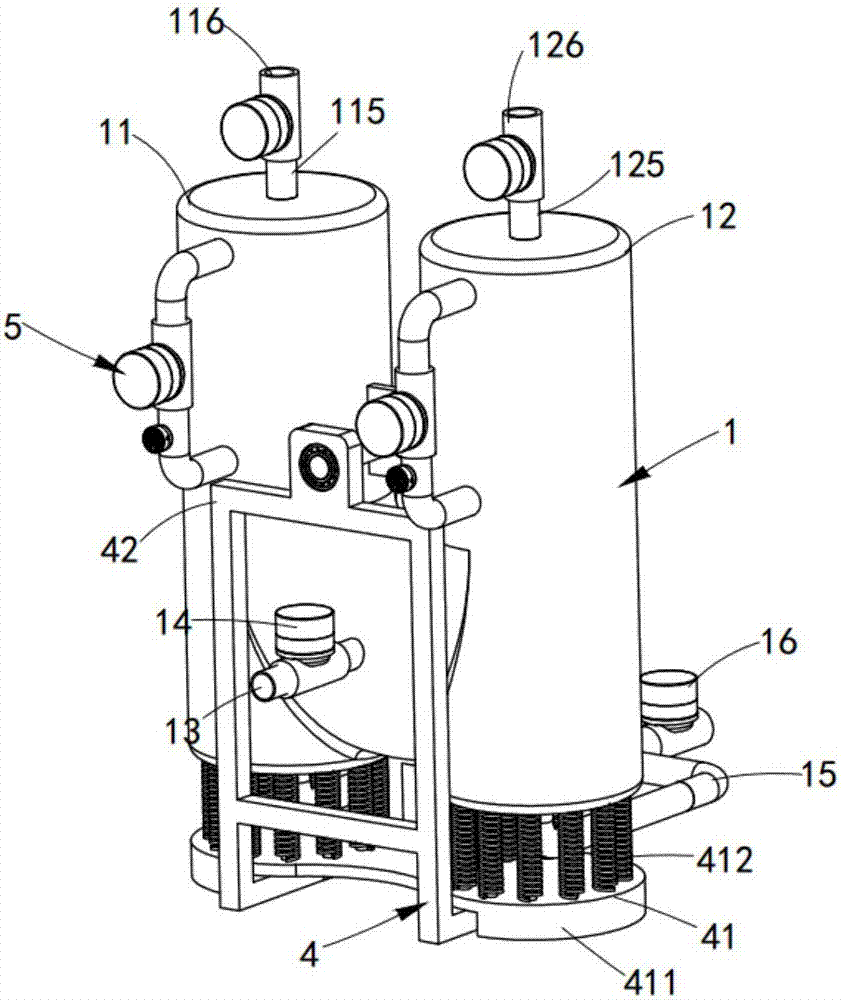

[0061] like figure 1 and figure 2 Shown, an automatic swing stirring foaming device, comprising:

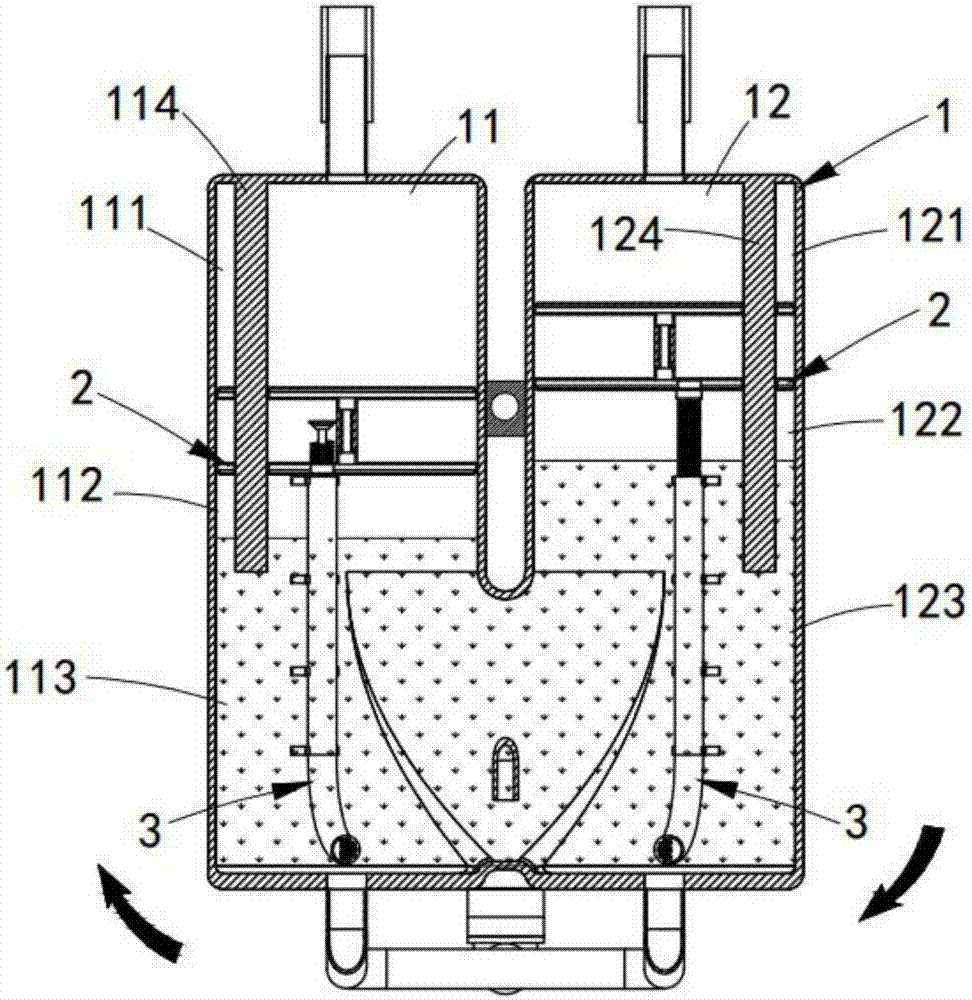

[0062] Foaming chamber 1, said foaming chamber 1 includes a first foaming area 11 and a second foaming area 12 arranged symmetrically, and the bottom of the first foaming area 11 and the second foaming area 12 communicate;

[0063] The pressure regulating air outlet mechanism 2, the pressure regulating air outlet mechanism 2 is respectively arranged in the first foaming area 11 and the second foaming area 12, and it is carried out along the inner wall of the first foaming area 11 and the second foaming area 12. Sliding longitudinally, and it includes a piston assembly 21 and an air outlet switch assembly 22;

[0064] The air injection mechanism 3, the air injection mechanis...

Embodiment approach

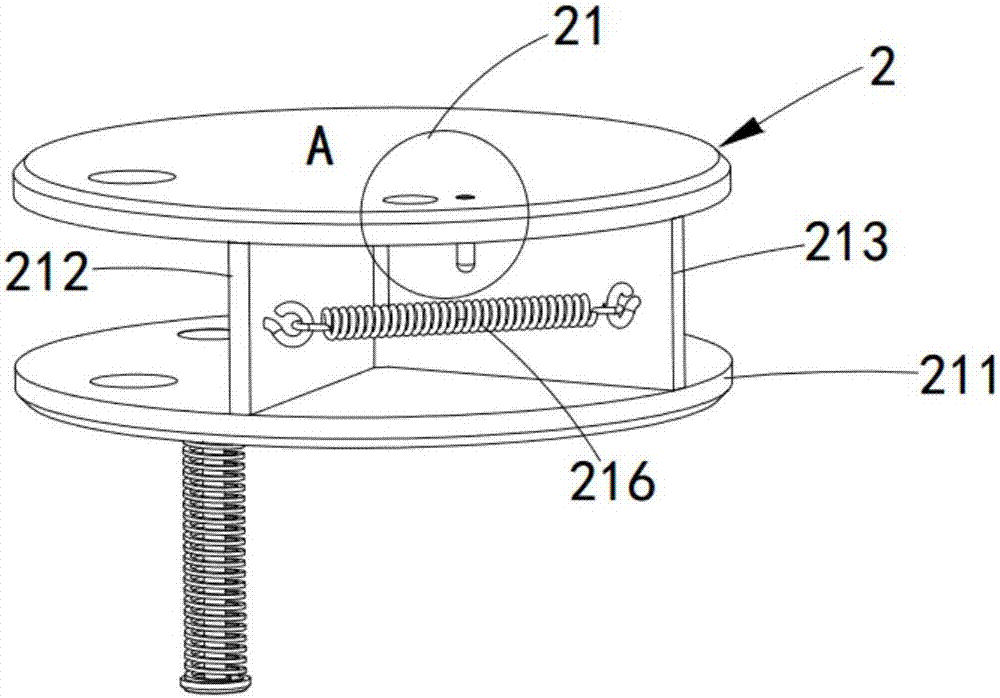

[0097] like Figure 11 As shown, as a preferred embodiment, the elastic component 41 includes:

[0098] A base 411, the base 411 is located directly below the foaming chamber 1, and its shape is consistent with the cross-sectional shape of the foaming chamber 1;

[0099] A plurality of springs 412, the springs 412 are respectively arranged below the first foaming area 11 and the second foaming area 12; one end thereof is connected to the base 411, and the other end thereof is connected to the first foaming area 11 It is connected with the lower end surface of the second foaming area 12;

[0100] A plurality of flexible pillars 413 are arranged inside corresponding to the spring 412 and arranged concentrically with the spring 412 .

[0101] like Figure 12 As shown, further, the support assembly 42 includes:

[0102] A support frame 421, the support frame 421 is arranged on both sides of the foaming chamber 1, the bottom of which passes through the base 411;

[0103] A rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com