Automatic charging unmanned aerial vehicle for power line inspection

A technology of automatic charging and power inspection, applied in electric vehicles, battery circuit devices, current collectors, etc., to achieve the effect of reducing control costs and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

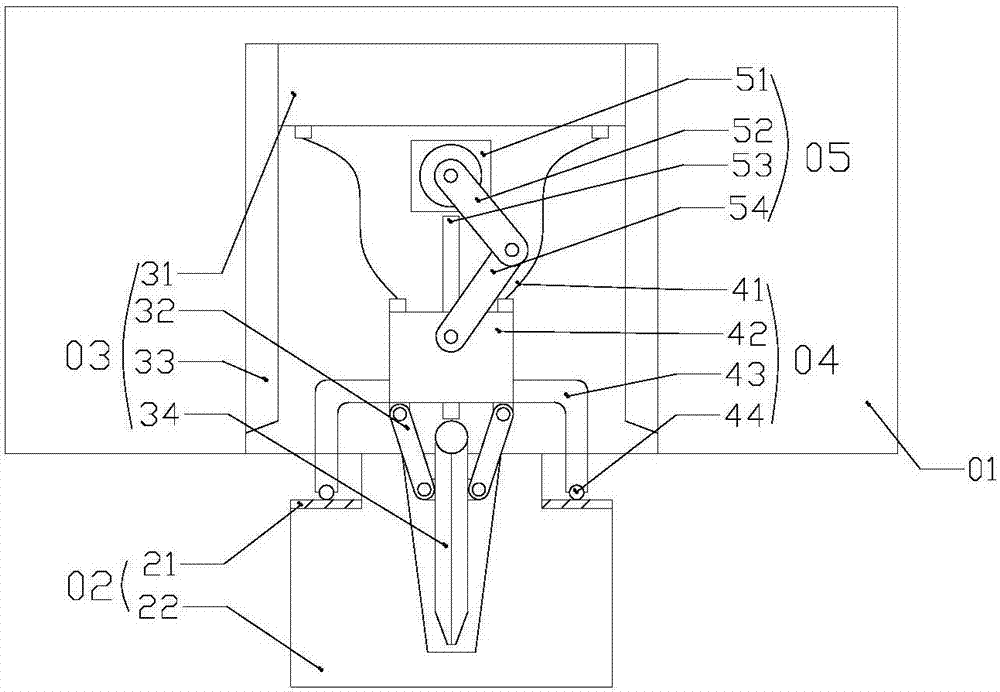

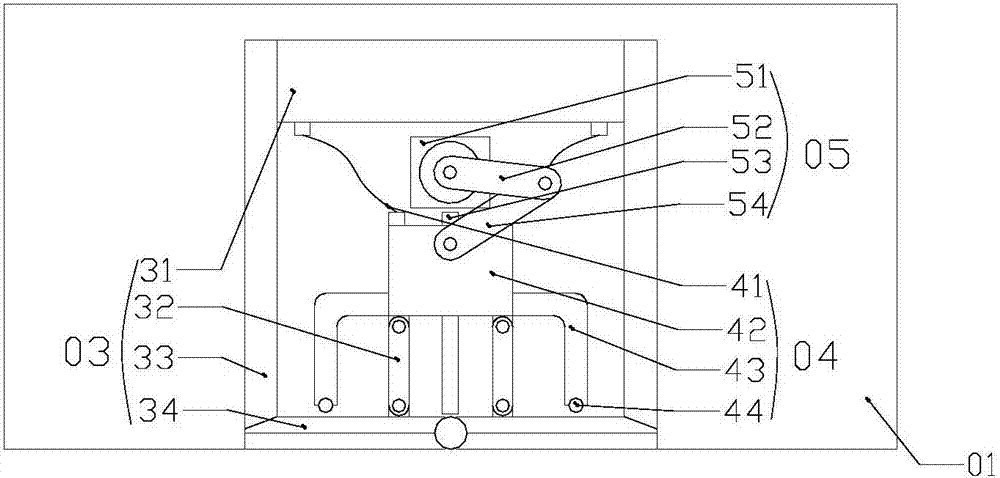

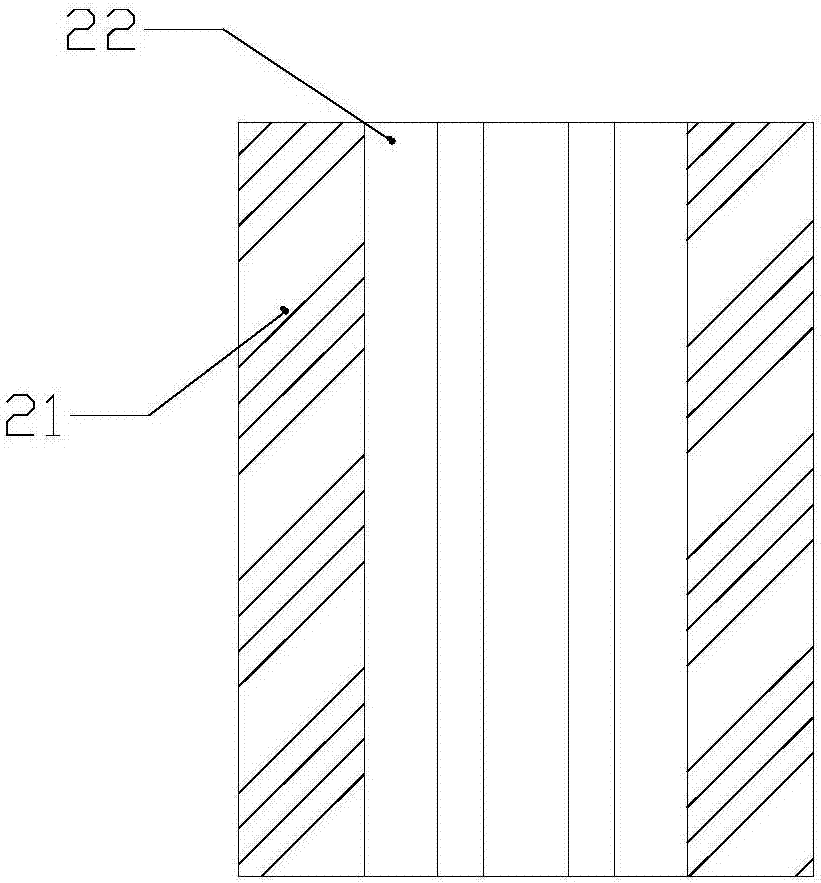

[0021] Such as figure 1 , figure 2 As shown, a kind of power inspection automatic charging drone provided by the present invention includes a battery compartment 03 located at the bottom of the drone 01, a drive mechanism 05 inside the battery compartment and a special plug 04; the battery compartment 03 is Insulating material, the battery compartment 03 includes a cabin body 33 with an opening downward, a battery 31 located above the cabin body 33, a hinged hatch door 34 opened from both sides to the middle, and a hatch door link hinged at one end to the inner wall of the hatch door 34 32. The hatch door 34 is opened outwards, and the joint surface of the hatch door 34 and the cabin body 33 is made into an oblique cut surface or a stepped shape that is fastened to each other. When the oblique cut surface is made, the cut surface is inward. effect, to prevent rainwater from flowing in, or to be blown into the cabin by the wind, if necessary, a layer of rubber can be added to...

Embodiment 2

[0035] Such as Figure 5 A kind of power inspection automatic charging UAV shown, the difference between embodiment 2 and embodiment 1 is that the driving mechanism 06; the driving mechanism 06 includes a rack 61, a gear 62 and a driving motor 63, and the output of the driving motor 63 The shaft is connected with the gear 62, the gear 62 meshes with the rack 61, and one end of the rack 61 is connected with the special plug 04; when the door is opened and closed, the drive motor 63 drives the gear 62 to rotate, and the gear 62 drives the rack 61 to move up and down in a straight line. Drive the hatch connecting rod 32 by the special plug 04 again, and the hatch connecting rod 32 drives the hatch door 34 to open and close. Equally, this mechanism also realizes two actions of opening the door and stretching out the plug by a drive.

Embodiment 3

[0037] Such as Figure 6 A kind of automatic charging unmanned aerial vehicle shown, the difference between embodiment 3 and embodiment 1 is that the drive mechanism 07; A synchronous 75; the hollow part of the second synchronous pulley 73 is a ball raceway, which can cooperate with the lead screw 71 to roll, and one end of the lead screw 71 is connected with the special plug 04; when opening and closing the door, the motor 71 drives the first synchronous pulley 75 Rotate, so that the synchronous belt 74 drives the second synchronous pulley 73 to rotate. According to the principle of the ball screw, the fixed-point rotation of the second synchronous pulley 73 can drive the screw 71 to do linear motion, and then the special plug 04 drives the cabin The door link 32 and the hatch link 32 drive the hatch 34 to realize the opening and closing of the hatch 34 . Equally, this mechanism also realizes two actions of opening the door and stretching out the plug by a drive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com