Continuous countercurrent supercritical extraction apparatus

A countercurrent supercritical and extraction device technology, which is applied in countercurrent extraction, solvent extraction, solid solvent extraction, etc., can solve problems such as unfavorable industrial production, achieve the effect of reducing loss and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] like figure 1 as shown,

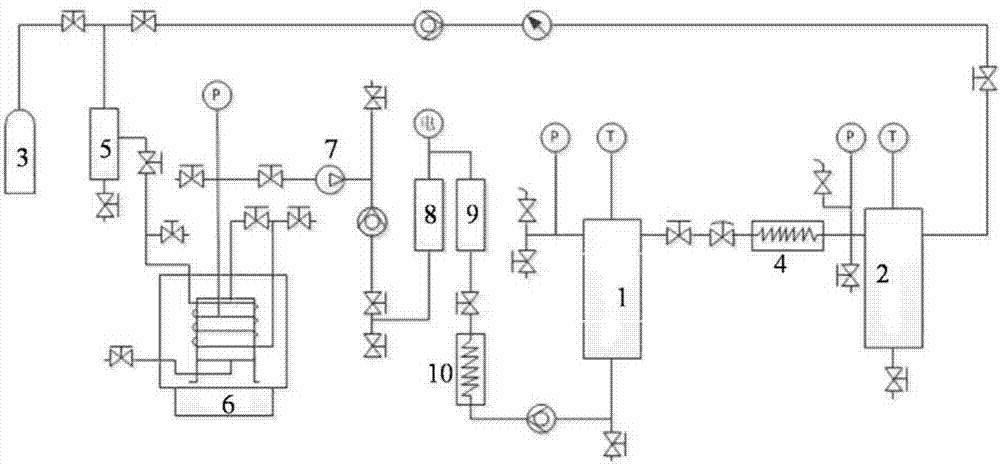

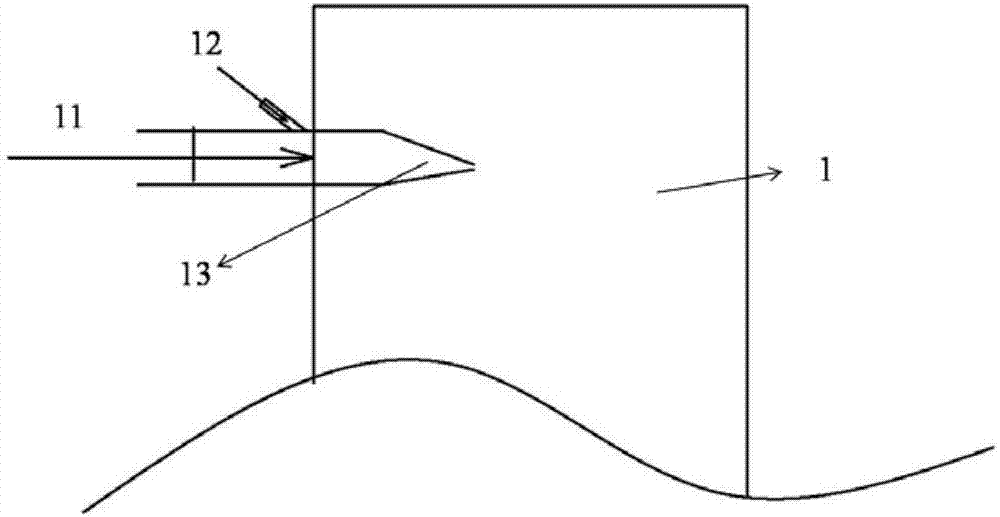

[0016] A continuous countercurrent supercritical extraction device, comprising an extraction kettle 1, a separation kettle 2 and a gas cylinder 3, the extraction kettle 1 and the separation kettle 2 are communicated through a first pipeline, the first pipeline is provided with a first heat exchanger 4, and the extraction There is a gas inlet at the bottom of kettle 1, and the gas inlet is connected with the gas cylinder 3 through the second pipeline. The extraction kettle 1 is provided with a raw material inlet, and a spray device is arranged at the raw material inlet, and the separation kettle 2 is connected with the gas inlet through the third pipeline. .

[0017] Also includes: first purifier 5, cold box 6, first metering pump 7, mixer 8, second purifier 9, second heat exchanger 10, gas cylinder 3 and first purifier 5 thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com