Concentration type health-preservation ginger beverage

A concentrated ginger drink technology, applied in the field of beverages, can solve the problems of poor blood circulation, side effects of painkillers, etc., and achieve the effect of clear marketing goals, improved nutrition and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

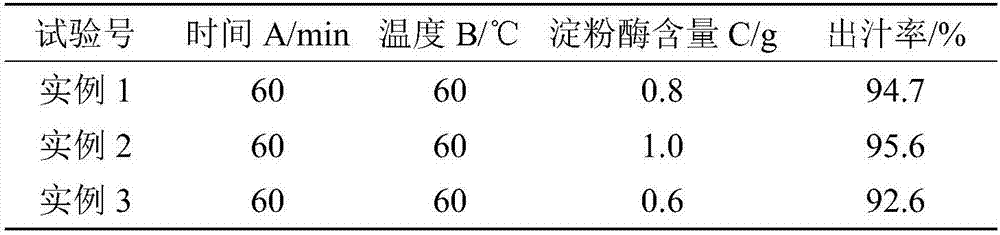

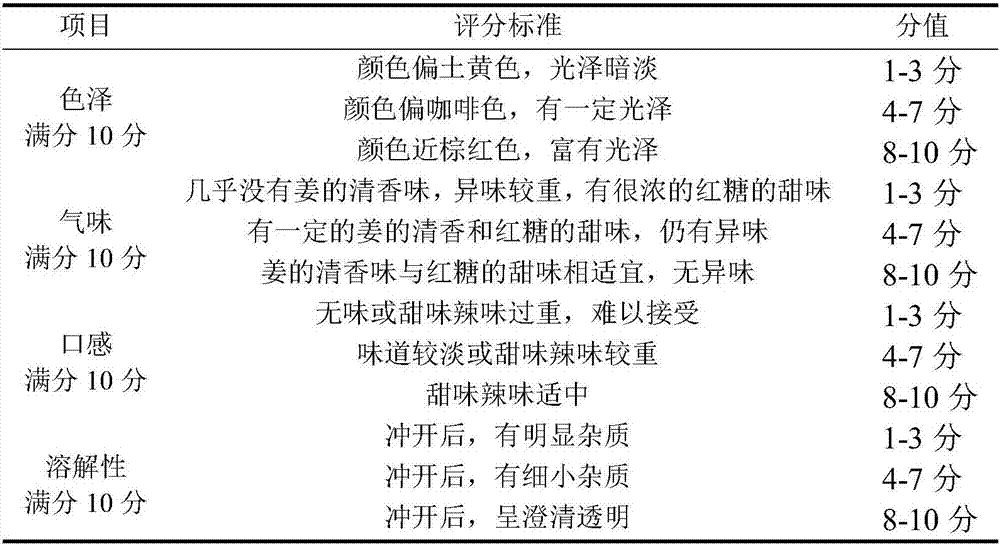

Embodiment 1

[0033] Choose fresh ginger that is tender and thick without moth-eaten rot, soak it in water, wash it, peel it, slice it, and take 160g for later use.

[0034] Add water at a material-to-liquid ratio of 1:2, add 1.5‰ citric acid, put it into a tissue masher for beating, put the slurry in an enzymatic hydrolysis tank, add 1.0g of amylase, stir well, and place the enzyme in a circulating water bath at 60°C After 60 minutes of hydrolysis, after the completion of enzymatic hydrolysis, the temperature was quickly raised to 90°C to inactivate the enzyme for 10 minutes, and then the temperature was lowered to about 40°C.

[0035] Use a 120-mesh sieve to filter out the coarse residue, extract the residue with 2 times the deionized solution at 85°C for 15 minutes, filter and squeeze the pulp, and combine the filtrates.

[0036] The filtrate was separated by centrifugation, the centrifugal speed was 3000r / min, and the centrifugation time was 8min. Take the supernatant to obtain clarifi...

Embodiment 2

[0042] Choose fresh ginger that is tender and thick without moth-eaten rot, soak it in water, wash it, peel it, slice it, and take 160g for later use.

[0043] Add water at a material-to-liquid ratio of 1:2, add 1.5‰ citric acid, put it into a tissue masher for beating, put the slurry in an enzymatic hydrolysis tank, add 0.8g of amylase, stir evenly, and place the enzyme in a circulating water bath at 60°C After 60 minutes of hydrolysis, after the completion of enzymatic hydrolysis, the temperature was quickly raised to 90°C to inactivate the enzyme for 10 minutes, and then the temperature was lowered to about 40°C.

[0044] Use a 120-mesh sieve to filter out the coarse residue, extract the residue with 2 times the deionized solution at 85°C for 15 minutes, filter and squeeze the pulp, and combine the filtrates.

[0045] The filtrate was separated by centrifugation, the centrifugal speed was 3000r / min, and the centrifugation time was 8min. Take the supernatant to obtain clari...

Embodiment 3

[0051] Choose fresh ginger that is tender and thick without moth-eaten rot, soak it in water, wash it, peel it, slice it, and take 160g for later use.

[0052] Add water at a material-to-liquid ratio of 1:2, add 1.5‰ citric acid, put it into a tissue masher for beating, put the slurry in an enzymatic hydrolysis tank, add 0.6g of amylase, stir well, and place the enzyme in a circulating water bath at 60°C After 60 minutes of hydrolysis, after the completion of enzymatic hydrolysis, the temperature was quickly raised to 90°C to inactivate the enzyme for 10 minutes, and then the temperature was lowered to about 40°C.

[0053] Use a 120-mesh sieve to filter out the coarse residue, extract the residue with 2 times the deionized solution at 85°C for 15 minutes, filter and squeeze the pulp, and combine the filtrates.

[0054] The filtrate was separated by centrifugation, the centrifugal speed was 3000r / min, and the centrifugation time was 8min. Take the supernatant to obtain clarifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com