A rotor core winding processing device

A technology for processing devices and rotor cores, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high labor intensity, low degree of mechanization, poor work efficiency, etc., to ensure winding accuracy, reduce Labor intensity and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

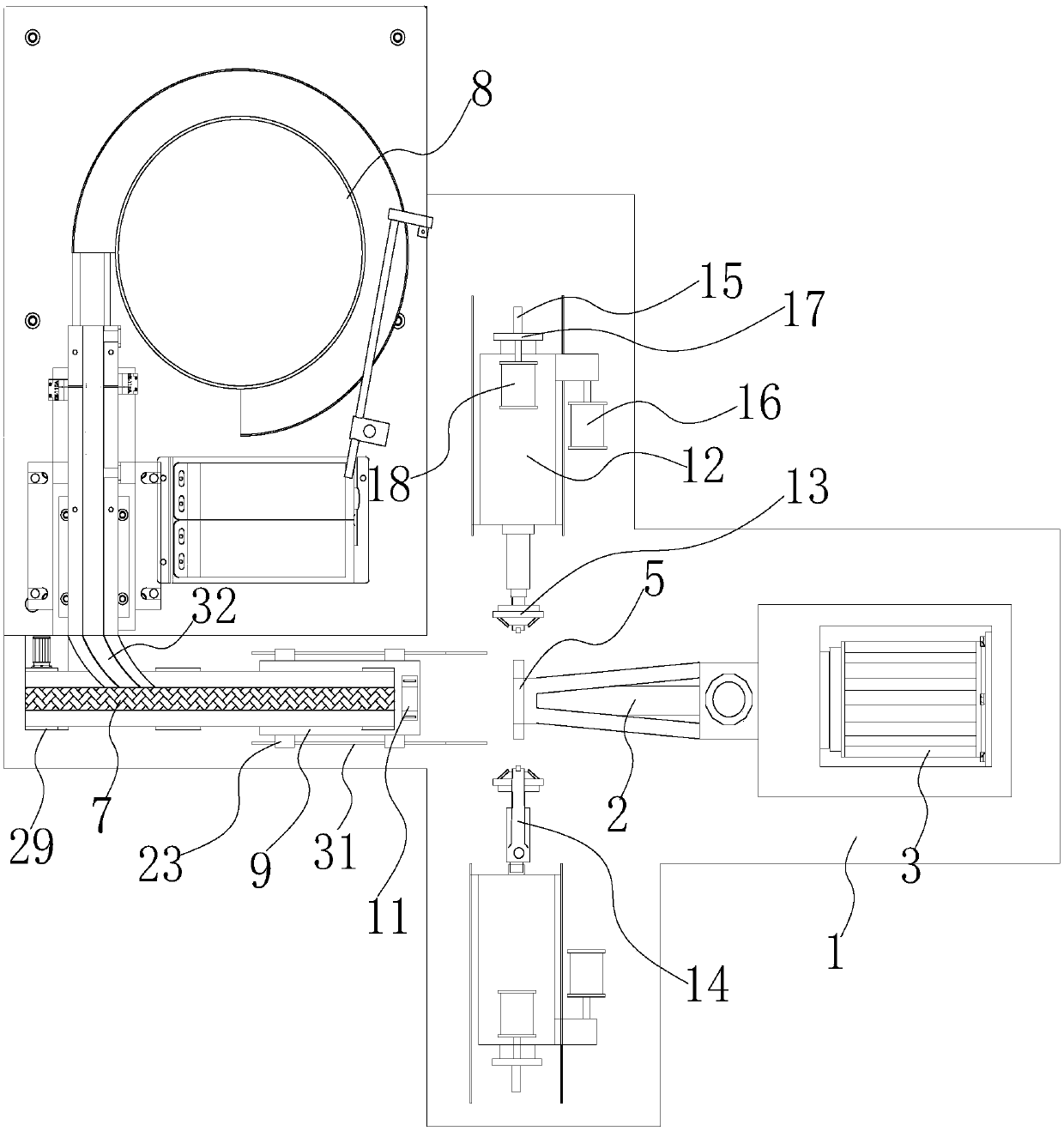

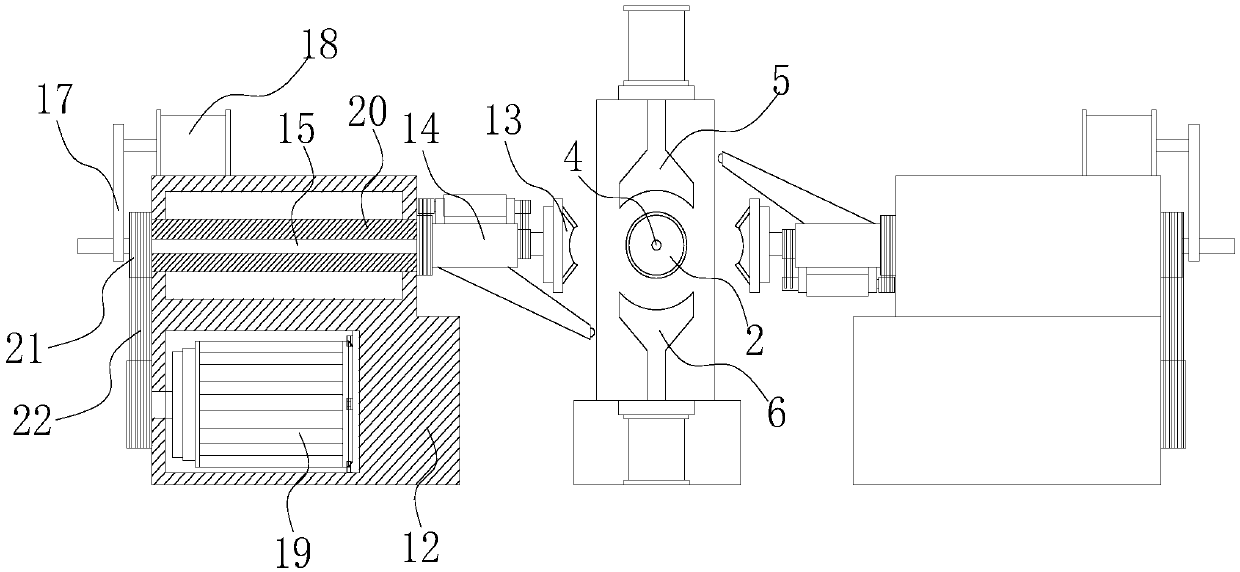

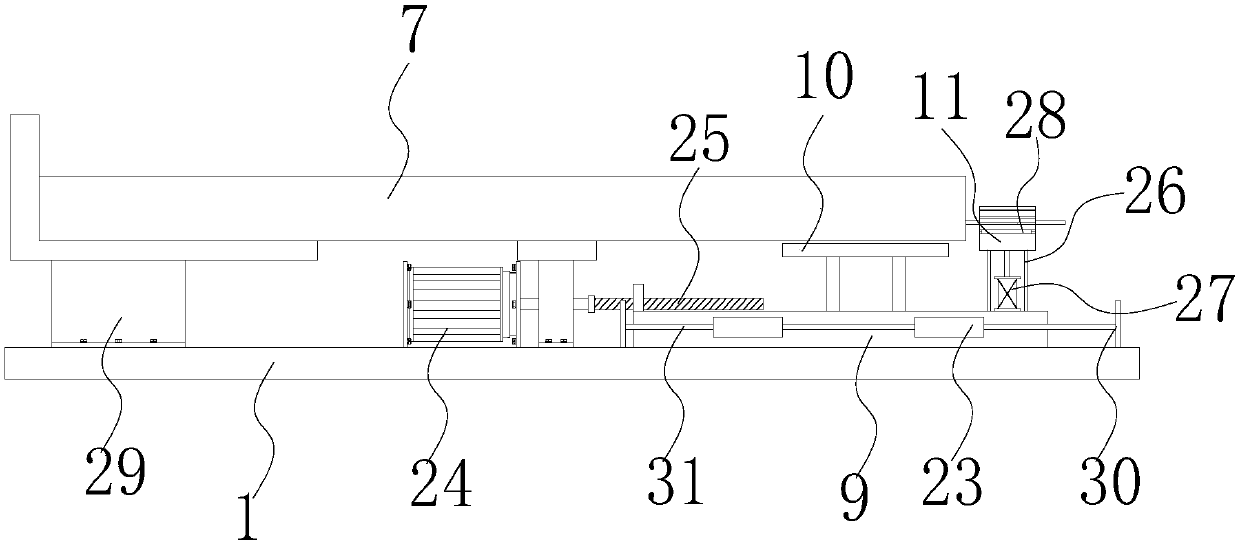

[0021] refer to Figure 1 to Figure 4 , the present invention includes a workbench 1 arranged horizontally, a conveying mechanism for conveying the rotor core, an indexing mechanism for fixing the rotor core, and left and right sides respectively located on both sides of the indexing mechanism. The winding mechanism, the indexing mechanism includes a suction cup sleeve 2 and a servo indexing motor 3 drivingly connected with the suction cup sleeve 2, the connection structure between the servo indexing motor 3 and the suction cup sleeve 2 is the prior art, and the suction cup The outer diameter of the sleeve 2 is smaller than the outer diameter of the rotor core, and one end of the suction cup sleeve 2 is suspended and fixed horizontally on the workbench 1, and the center of the suction cup sleeve 2 is provided with a rotating shaft for the rotor core. Insert the shaft hole 4, the servo indexing motor 3 can drive the suction cup sleeve 2 to rotate several angles, the servo index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com