Switching valve with built-in circulation channel structure

A flow channel, switching valve technology, applied in the application field of valve structure, to reduce wear and improve overall performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

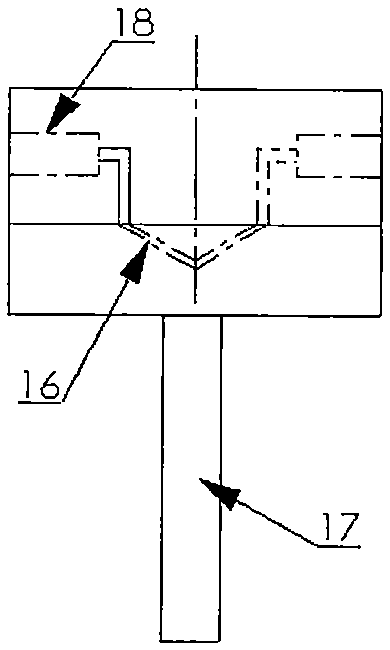

[0037] The present invention will be further described below in conjunction with the accompanying drawings. The expressions and terminology about mechanical dimensions and positions in the following description process are all for the purpose of describing the patent of the present invention clearly, so they cannot be used as restrictions on the patent of the present invention. This means that as long as there is no innovative design condition, only changes or adjustments in position, size, processing method and shape all belong to the protection scope of the patent of the present invention.

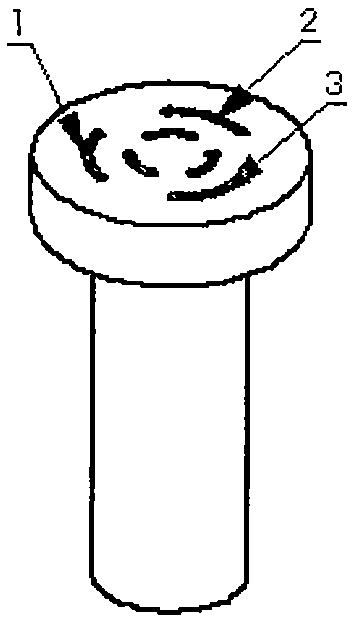

[0038] figure 2 It is a schematic diagram of the rotor structure of the switching valve in the prior art, which is composed of concentric arc grooves. If it is a six-way switching valve, there are three arc grooves, and if it is a 12-way valve, there are six arc grooves.

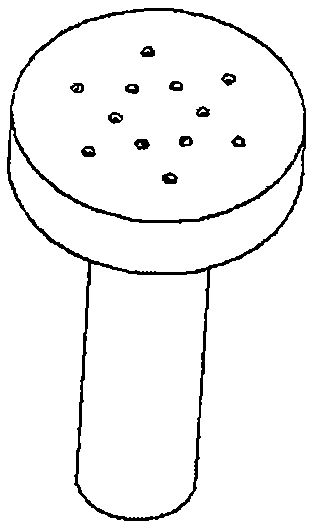

[0039] image 3 It is a schematic diagram of the patented rotor of the present invention. In order to express mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com