Automatic turning and demolding method and device of delay element inner tube

An automatic flipping and delaying technology, applied in the direction of offensive equipment, ammunition, weapon accessories, etc., can solve problems such as damage, and achieve the effects of avoiding easy damage, stable product quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1 of the present invention: the method of automatically flipping and ejecting the inner tube of the delayed body, the inner tube that has been filled and compacted with the delayed body is transported on the conveyor belt with a transfer mold, and the transfer mold is carried out from the conveyor belt by a manipulator. Turn over 180° to make the top face down and the bottom face up, and continue to be transported to the bottom of the ejection device through the conveyor belt. Tubes drop into collection boxes for collection.

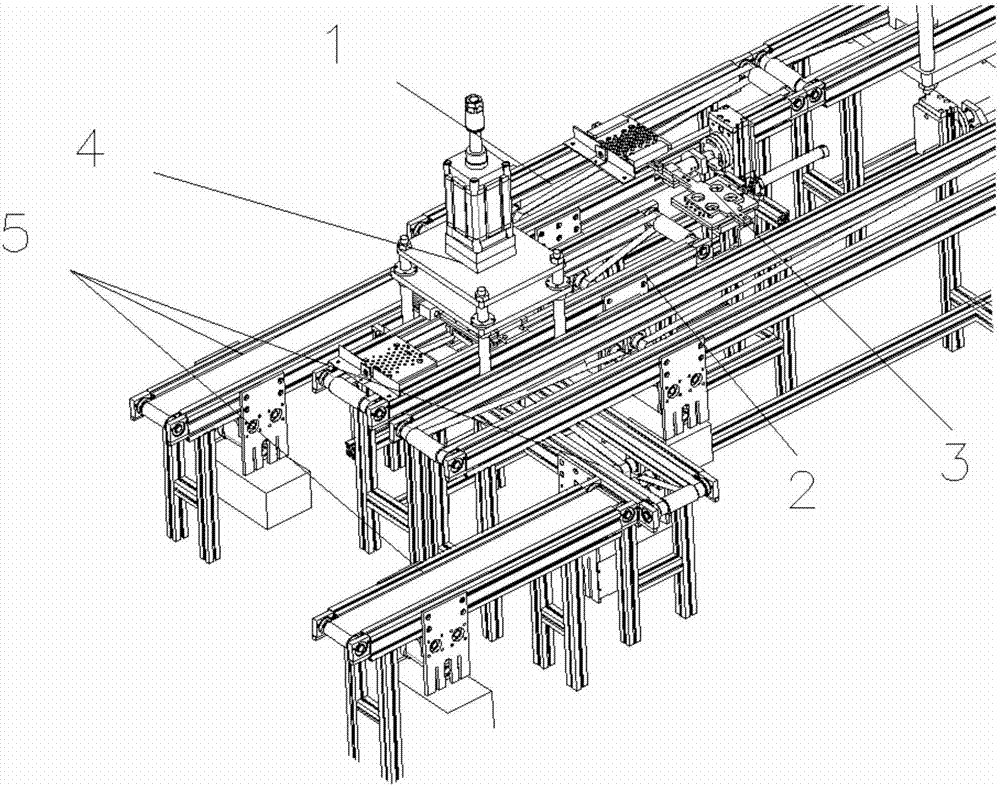

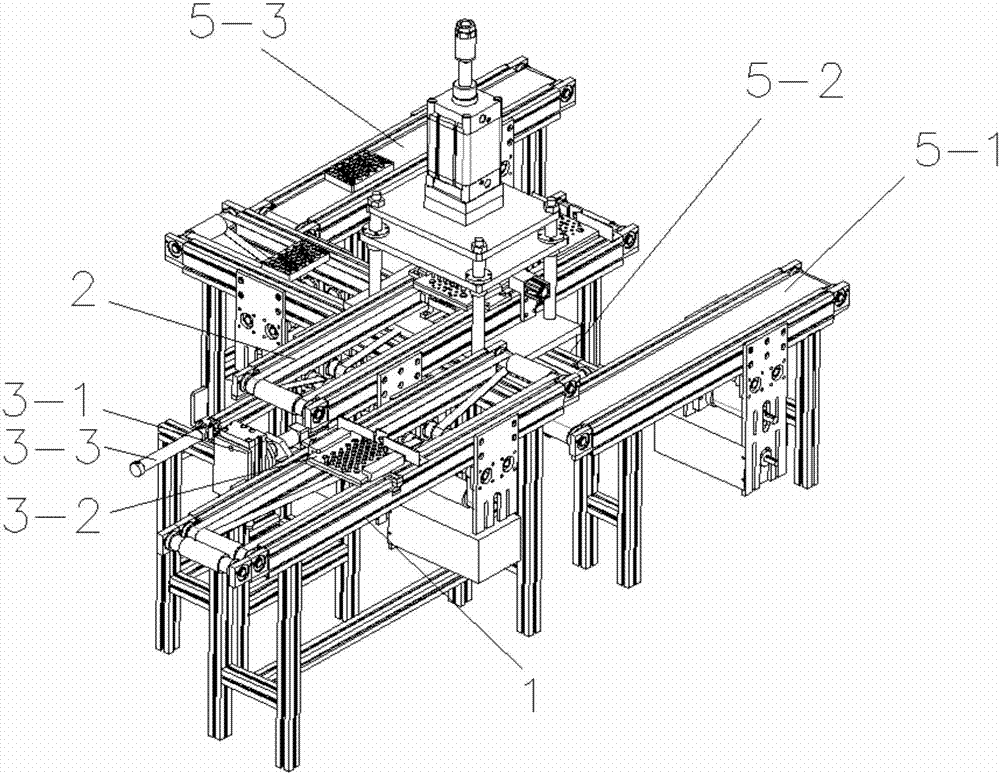

[0011] The device for automatically flipping and ejecting the tube in the body of the delay includes a positive mold conveying section 1, and a counter mold conveying section 2 parallel to it is arranged on one side of the positive mold conveying section 1, and between the positive mold conveying section 1 and the counter mold conveying section 2 There is an overturning manipulator 3 between them, an ejector device 4 is provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com