Classified filtering engine oil filter assembly for motorcycle engine

A technology of oil filter and graded filtration, which is applied in the installation/connection of lubricant purification device, lubricating parts, pressure lubricant, etc., which can solve problems such as shedding, limited separation effect, and unfavorable improvement of engine life, so as to achieve improvement Effects of service life, reduction of abnormal wear and seizure, and improvement of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

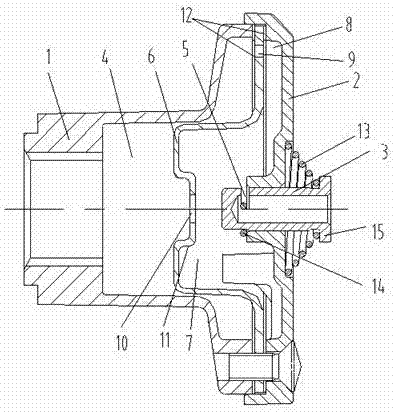

[0014] see figure 1 , as can be seen from the figure, the motorcycle engine graded filter oil filter assembly of the present invention includes a filter rotor 1, a filter cover 2 and a crankshaft oil pipe 3, and the center of the filter rotor 1 has a stepped structure The cavity 4 and the filter cover 2 are fixedly connected to the end with a large inner diameter of the filter rotor cavity by screws. There is a mounting hole in the center of the filter cover, the crankshaft oil pipe is installed in the mounting hole and one end of the crankshaft oil pipe is located in the cavity, and the other end is located outside the cavity. Radial oil outlet 5.

[0015] In the present invention, a filter partition 6 is added in the filter rotor cavity 4, and the edge of the filter partition 6 is installed and fixed between the filter cover 2 and the end face of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com