A device for reverse demolition of dense high-rise buildings and its application method

A building and high-rise technology, applied in building construction, construction, building maintenance, etc., can solve problems such as building stability control problems, and achieve the effect of maintaining vertical direction and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

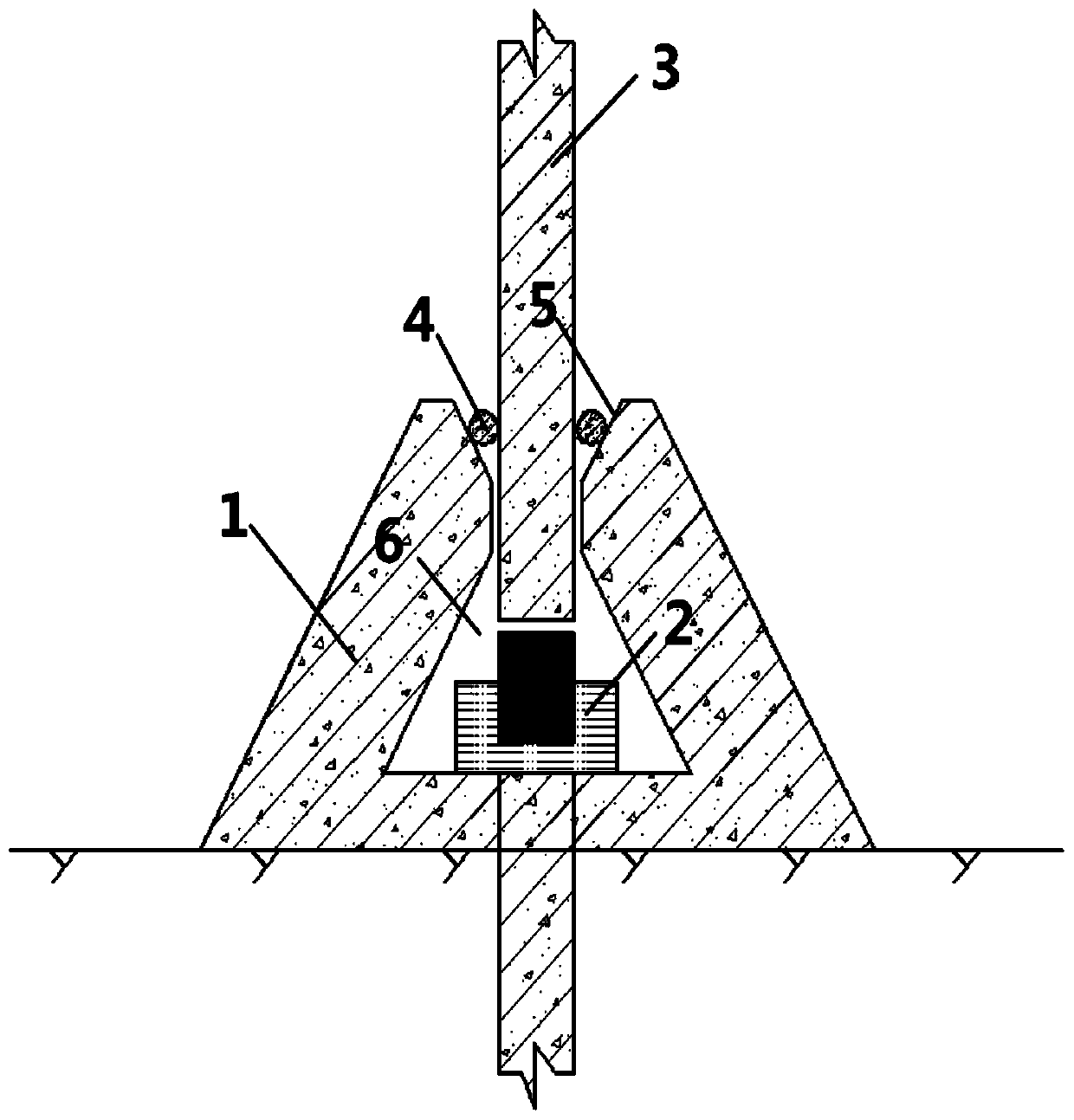

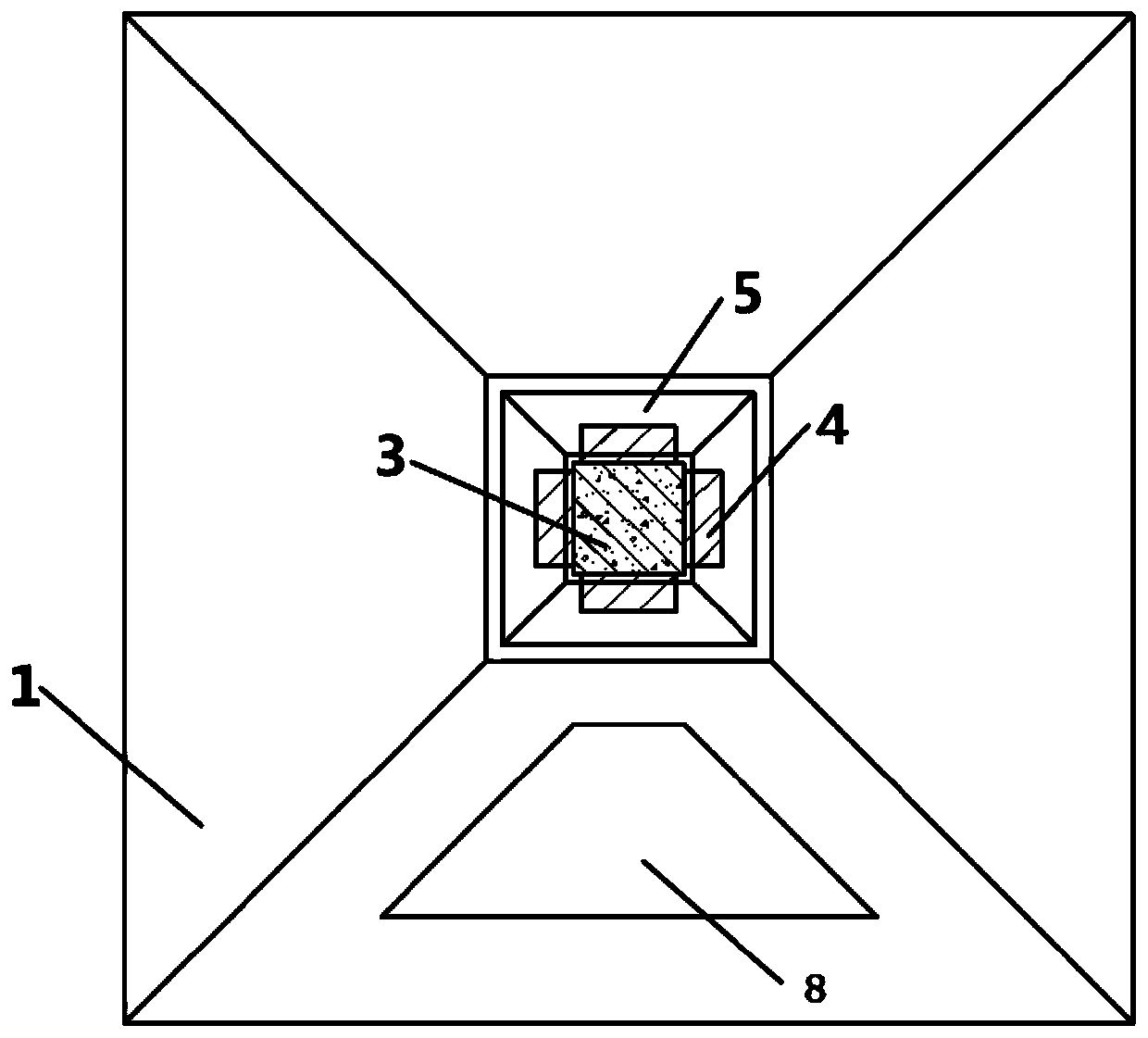

[0030] Such as figure 1 As shown, a reverse demolition device for a dense high-rise building includes a support pier 1 poured around the load-bearing column 3, the inner bottom of the support pier 1 is provided with a hollow cavity 6, and the side of the support pier 1 is provided with a hollow cavity 6 The connected operation hole 8 cuts off the load-bearing column 3 in the cavity 6 of the support pier 1 and replaces it with a jack 2. The upper part of the support pier 1 is set as an inclined surface 5, and the distance between the upper inclined surface 5 of the support pier 1 and the load-bearing column 3 Large and small, a plurality of rolling elements 4 are arranged between the upper inclined surface 5 of the support pier 1 and the load-bearing column 3 .

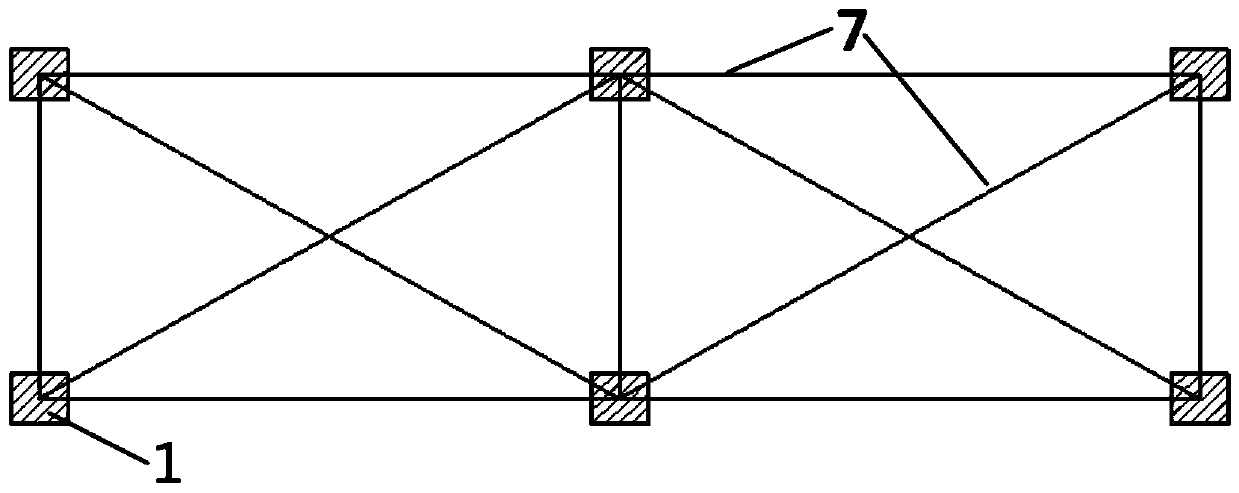

[0031] The outside of the supporting pier 1 is in the shape of a prism with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com