A kind of high-performance aramid fiber cable for fire prevention and heat insulation

A high-performance, aramid fiber technology, used in flame-retardant fibers, fiber processing, textiles and papermaking, etc., can solve the problems of deterioration of mechanical properties, poor heat resistance, etc., achieve good fire and heat insulation effects, reduce costs, and protect The effect of the inner cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the fire-proof and heat-insulating high-performance aramid rope of this embodiment includes the following steps:

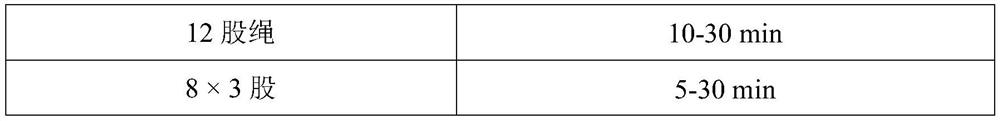

[0035] 1. Wash the braided 12-strand aramid rope with water and dry it, then add it to a phosphoric acid solution with a mass fraction of 20%, soak it for 30 minutes at 20°C, take it out and wash it with distilled water until neutral.

[0036] The preparation method of the pretreatment solution is as follows: directly add the acid to the water and stir well.

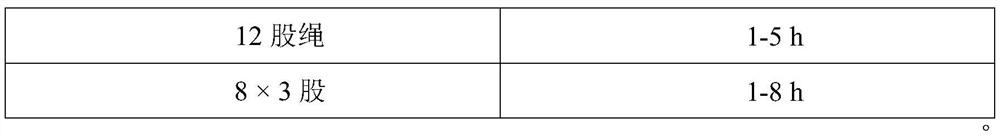

[0037] 2. Soak the rope in the functional coating for 30 minutes, take it out for low-temperature cross-linking and curing, bake at 50°C, and bake for 5 hours to prepare a fireproof and heat-insulating high-performance aramid rope. The functional coating comprises the following components:

[0038] components Component Specific Name Content (parts by weight) Chitosan Chitosan 40 copies polyvinyl alcohol polyvinyl alcohol 5 copies flame ret...

Embodiment 2

[0045] The preparation method of the fire-proof and heat-insulating high-performance aramid rope of this embodiment includes the following steps:

[0046] 1. Wash the braided 12-strand aramid rope with water and dry it, then add it to the phosphoric acid pretreatment solution with a mass fraction of 40%, soak it at 20°C for 20 minutes, take it out and wash it with distilled water until neutral.

[0047] The preparation method of the pretreatment solution is the same as in Example 1.

[0048] 2. Soak the rope in the functional coating for 20 minutes, take it out for low-temperature cross-linking and curing, bake at 50°C for 2 hours, and prepare a fireproof and heat-insulating high-performance aramid rope. The functional coating comprises the following components by weight:

[0049] components Component Specific Name Content (parts by weight) Chitosan Chitosan 57 copies polyvinyl alcohol polyvinyl alcohol 20 copies flame retardant DOPO 20...

Embodiment 3

[0056] The preparation method of the fire-proof and heat-insulating high-performance aramid fiber rope of this embodiment includes the following steps:

[0057] 1. Wash the braided 12-strand aramid rope with water and dry it, then add it to a phosphoric acid solution with a mass fraction of 60%, soak it at 20°C for 10 minutes, take it out and wash it with distilled water until neutral.

[0058] The preparation method of the pretreatment solution is the same as in Example 1.

[0059] 2. Soak the rope in the functional coating for 10 minutes, take it out for low-temperature cross-linking and curing, bake at 50°C for 1 hour, and prepare a high-performance aramid fiber cable for fire protection and heat insulation. The functional coating comprises the following components by weight:

[0060] components Component Specific Name Content (parts by weight) Chitosan Chitosan 80 copies polyvinyl alcohol polyvinyl alcohol 10 copies flame retardant di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com