Trim part for a motorcycle or a motor scooter, and trim unit consisting of a plurality of trim parts

A technology for motorized scooters and motorcycles, used in bicycle accessories, weather guards, transportation and packaging, etc., can solve problems such as violation of seams, difficulty in production or painting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

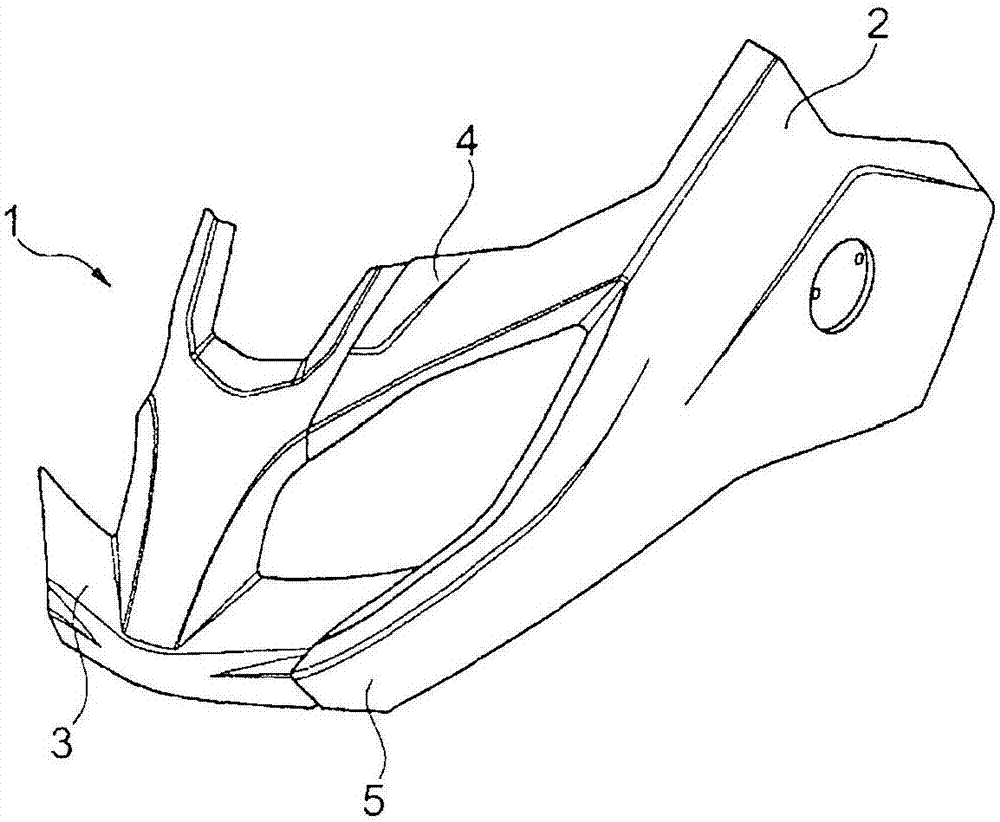

[0019] 1 shows a perspective view of a trim unit 1 for a motorcycle headlight, which is made of the figure 2 The decorative panel part 2 shown separately in the figure is composed of another decorative panel part 3 positioned, aligned and fastened on the decorative panel part. Other components used to form the complete headlight fascia are omitted for clarity.

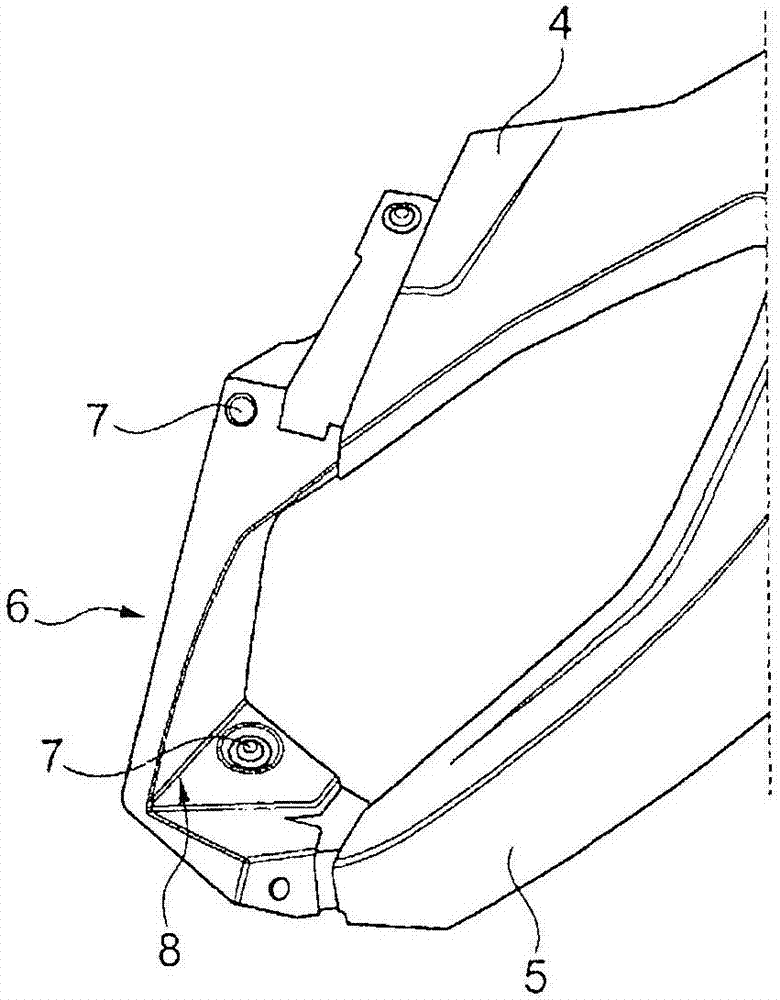

[0020] refer to figure 1 and figure 2 , the trim part 2 comprises two freely extending legs 4 , 5 which each have a free end and an end pointing towards the other trim part 3 . In the embodiment shown, the legs 4 , 5 form a gap between them for a headlight glass, not shown. At the free ends of the legs 4 , 5 , on their respective rear sides and at a distance from the view side, a bridge 6 is formed, which closes or encloses the contour and thus encloses or encloses the opening. The gap in the headlight glass. as in figure 1 As shown in , the trim part 3 is placed on the bridge 6 in such a way that the two trim ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap