Frictional power generation measurement system based on Labview, and analysis method of frictional power generation measurement system

A technology of triboelectric power generation and measurement system, which is applied in the direction of electric power measurement, measurement device, and measurement of electric variables through current/voltage, which can solve the problem that the performance of various electrical parameters of the device cannot be monitored at the same time, the hardware cannot be improved, and the price of measurement equipment Expensive and other problems, to achieve the effect of improving measurement efficiency, saving time and manpower, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

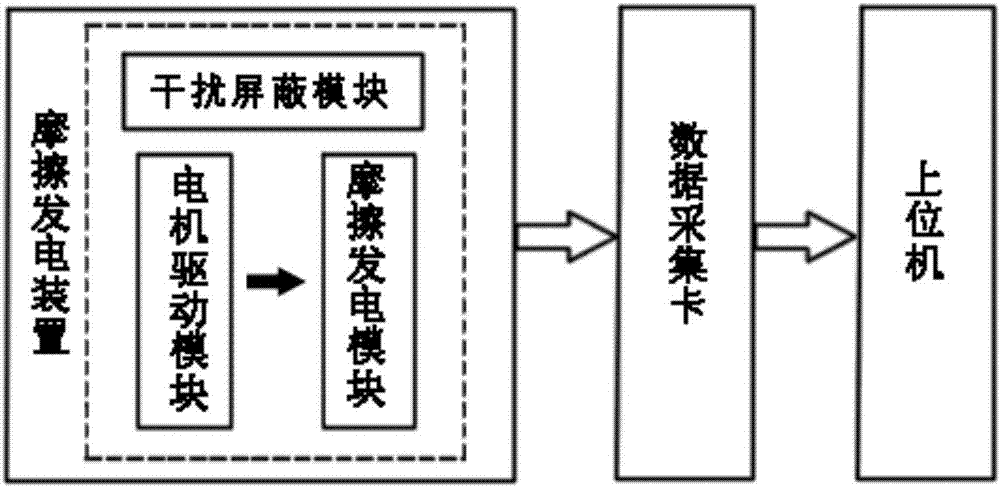

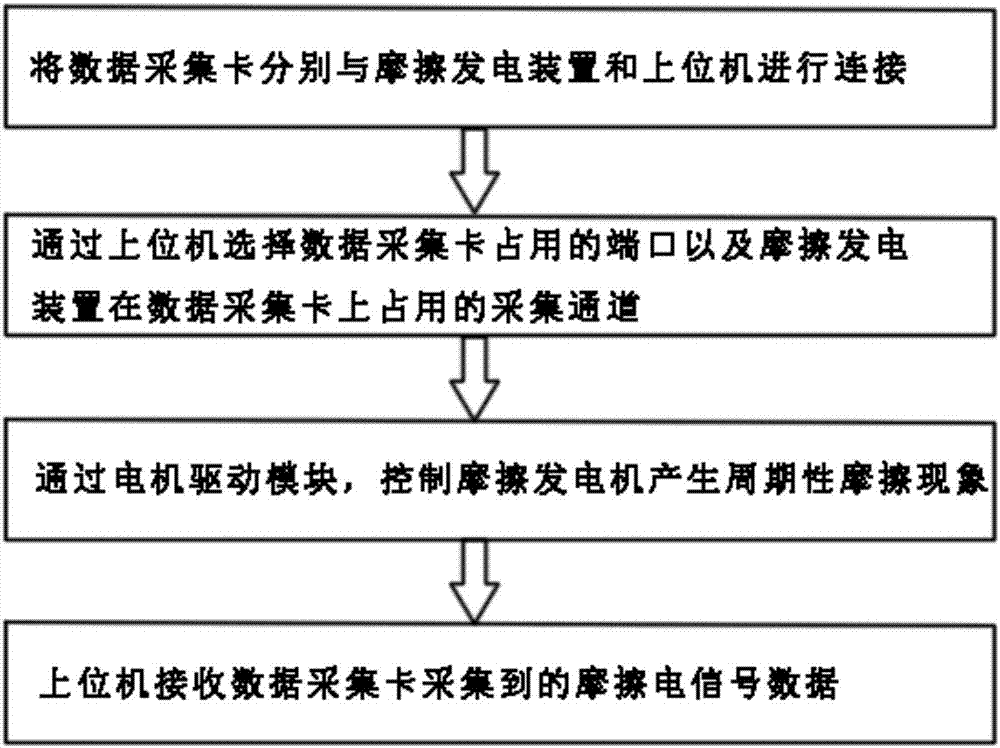

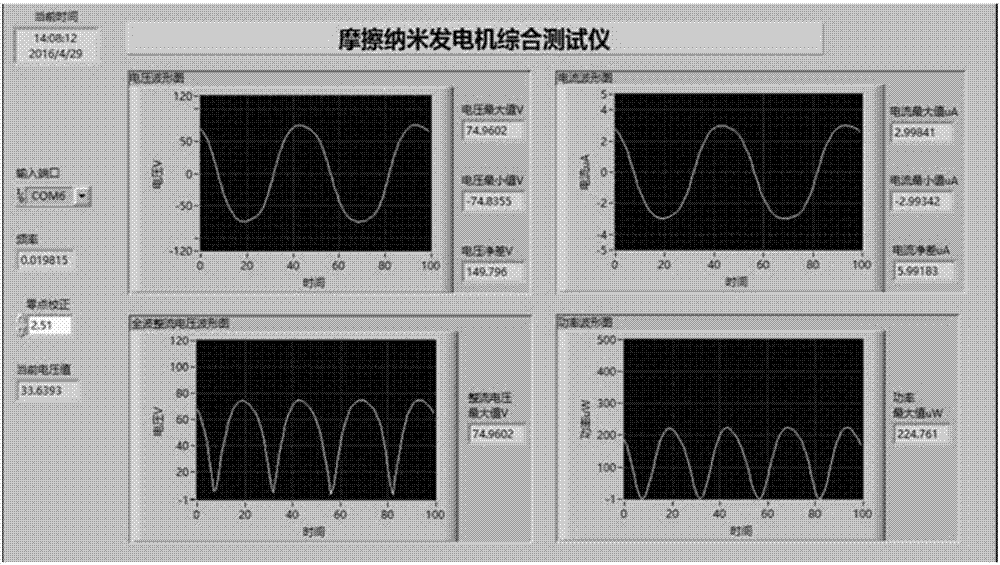

[0033] A test system for triboelectric generation based on Labview is mainly composed of hardware and modules. The hardware part is composed of friction power generation device I, data acquisition card II and host computer III. The Labview analysis module is composed of man-machine interface program module, acquisition control and measurement module, module filtering module, waveform analysis module and data post-processing module.

[0034] The friction power generation device module in this embodiment includes three parts: a friction power generation ball module, a motor drive module, and an interference shielding module. The friction power generation module of this embodiment adopts a spherical power generation body based on an independent friction structure. The above-mentioned embodiment 1 is only an example, and the selection based on the spherical triboelectric generator is only an example, not a limitation to the method of the present invention. You can also choose fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com