Frame component of solar photovoltaic module

A solar photovoltaic and frame technology, which is applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of affecting the service life of solar panels, wasting the sealing effect of sealing materials, and complex structure of sealing strips, so as to save production costs. , the effect of enhancing toughness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

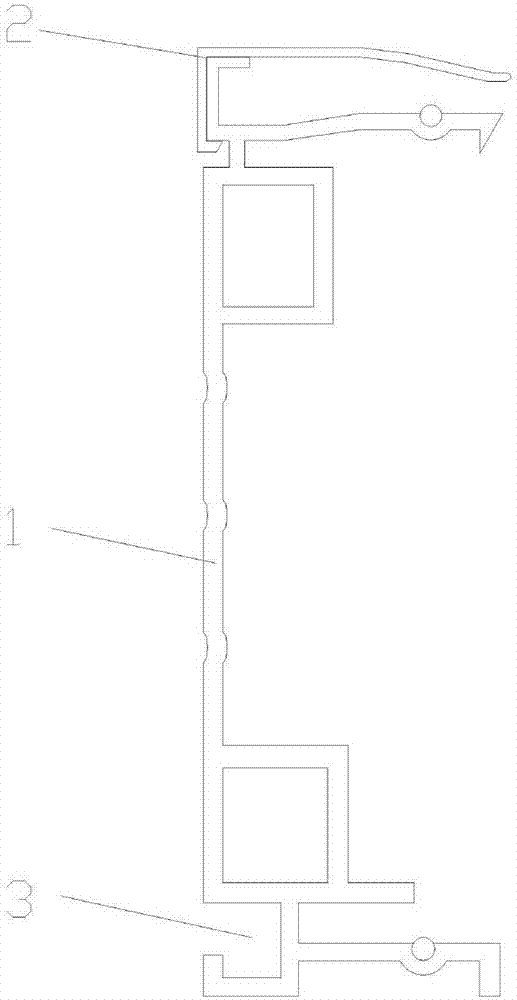

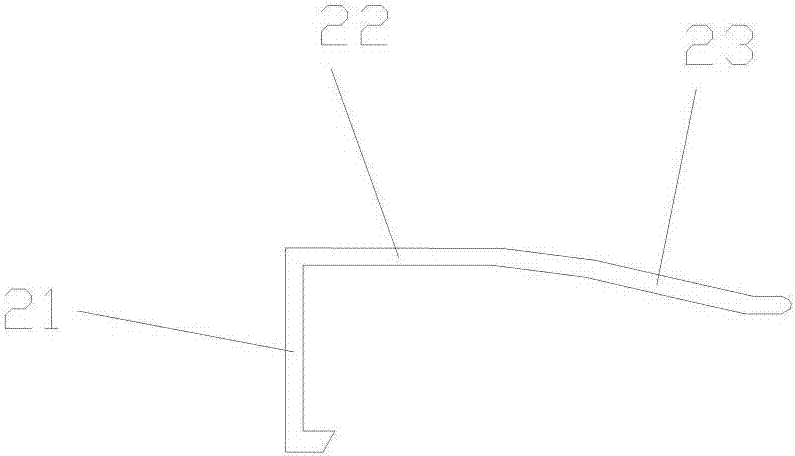

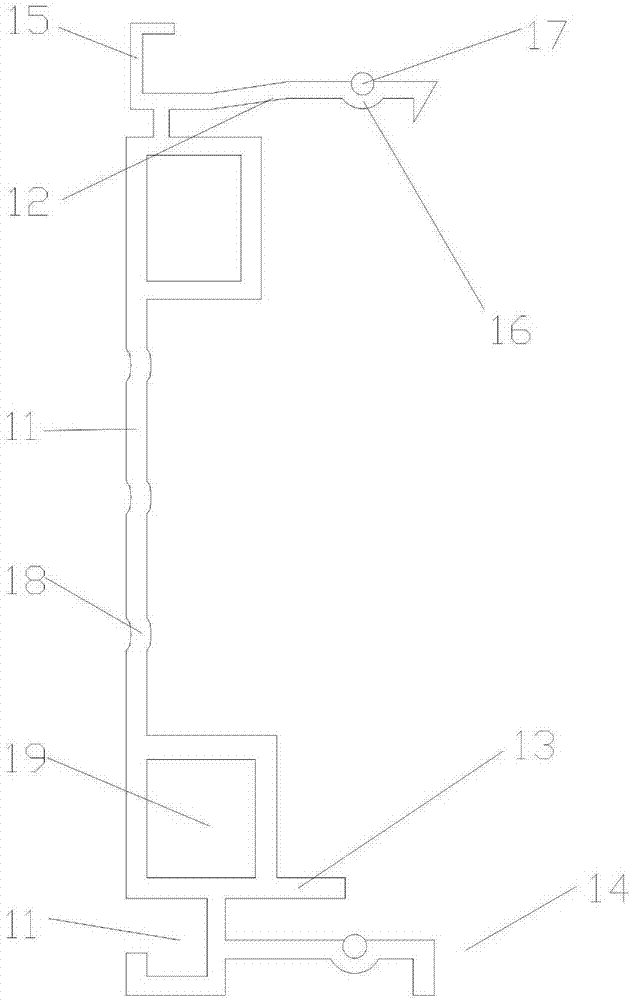

[0022] The purpose of this embodiment is to provide a solar photovoltaic module frame member, such as Figure 1 ~ Figure 3 As shown, the frame member includes a frame body 1 and a bead 2 that is engaged with the frame body; the bead includes a hook-shaped vertical edge 21 that is engaged with the frame body, and a horizontal edge 22 that is arranged at the top of the hook-shaped vertical edge; The frame main body 1 includes a vertical frame 11, a first horizontal frame 12 and a third horizontal frame 14 that are respectively arranged at the upper and lower ends of the vertical frame and are in the same direction as the horizontal side 22, and are arranged on the vertical frame above the third horizontal frame 14, Used to cooperate with the third horizontal frame t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com