Multi-cylinder type gas compressor

A gas compressor and multi-cylinder technology, which is applied in the field of gas compressors, can solve the problems of low gas compression efficiency, many moving parts, and large vibration, and achieve the effects of high gas compression efficiency, less moving parts, and small working vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

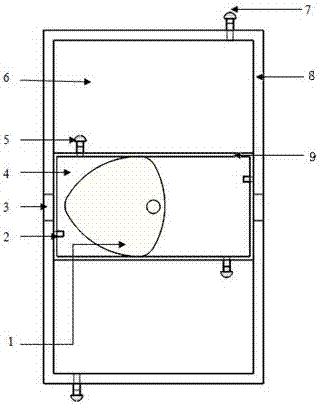

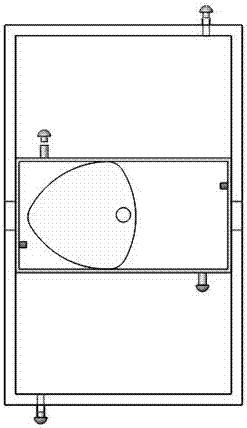

[0026] Specific implementation: as figure 1 As shown, a multi-cylinder gas compressor includes a cylinder block 8, wherein an intermediate frame body 9 is provided in the middle of the cylinder cavity (the intermediate frame body can be a frame structure surrounded by four sides or also It can be a closed box structure), the middle frame 9 is slidably fitted in the inner cavity of the cylinder 8 and separates two secondary compression chambers 6 from both ends of the cylinder cavity along the sliding direction. The inner cavity forms an air intake chamber, and an equal-width cam 1 is arranged in the inner cavity of the middle frame. The rotation direction of the equal-width cam 1 is consistent with the sliding direction of the middle frame body, and the middle frame body is located at the two sides of the two secondary compression chambers. The inner side walls are used to contact with both sides of the equal-width cam when it rotates to form an equal-width cam mechanism. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com