Replacement method in hole for main drive sealing failure of earth pressure balance shield machine under normal pressure

A technology of earth pressure balance and sealing failure, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of large impact on project construction, high cost, and long duration of technical solutions, so as to improve construction progress and work efficiency. Low cost and the effect of improving the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

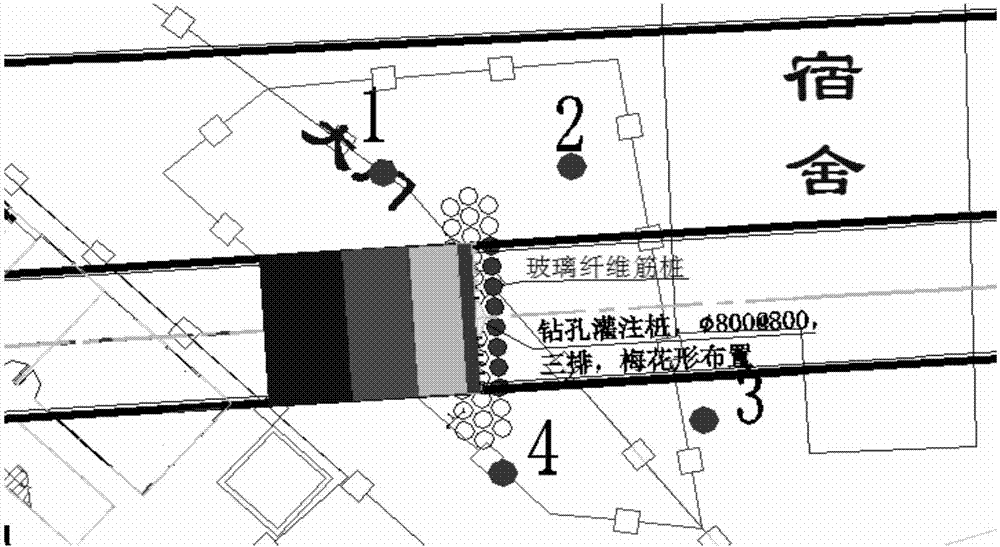

[0052] Right line shield opening position

[0053] 1. Industrial and mining introduction: The tunnel between Station X and Station B (XB section) is constructed using the shield method. The shield section starts from the south end of Station X, passes through the middle air shaft, and reaches Station B. The shield section goes south along Wanquanhe Road and passes through the pile foundation of the X Bridge, the section tunnel of Metro Line 4, the overpass on the south side of the X Hospital, and the office buildings in the A Township plot, crosses the Xinjian Gongmen Road vertically, and then passes through the basement A security Pavilion structure, turn east and cross A park and its man-made lake, and arrive at station B on the northwest side of area C.

[0054] The interval from X to B is the double-line shield interval. The design mileage of the left line is BK19+694.200~BK21+323.007, and the design mileage of the right line is BK19+694.200~BK21+346.514. There is one lo...

Embodiment 2

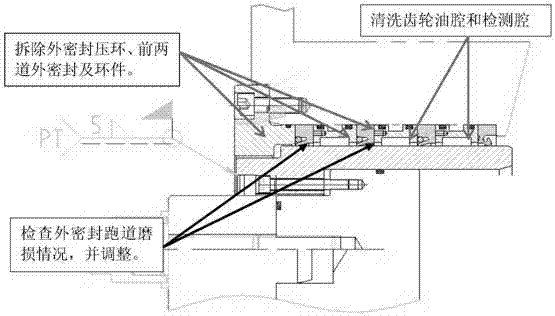

[0104] Example 2 Replacement in the outer sealing hole of the main drive

[0105] 1. Program introduction

[0106] According to the current inspection and continuous observation of China Railway No. 212 (HBW, EP2 and a small amount of sediment were found in the inspection chamber, and the gear oil level did not drop), it is preliminarily inferred that the first three seals have failed, and the fourth seal is intact. The general plan is: remove the first two seals (due to the limitation of space size, only the first two seals can be replaced in the hole without dismantling the cutter head), check the wear of the sealing runway, move the runway up 8mm, and clean the gears Oil chamber, detection chamber and drive box, bonded and sealed, installed seal and spacer ring, pressure ring, welded sealing plate, and carried out static load and dynamic test of outer seal.

[0107] 2. Put gear oil and clean the drive box

[0108] Drain the gear oil in the drive box through the oil outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com