A processing method for the top structure of a residential container

A processing method and container technology, applied to tools for roof engineering, building structures, roofs, etc., can solve problems such as unfavorable, impossible to build, difficult to effectively improve yield and production efficiency, etc., to achieve novel structure, The effect of novel and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

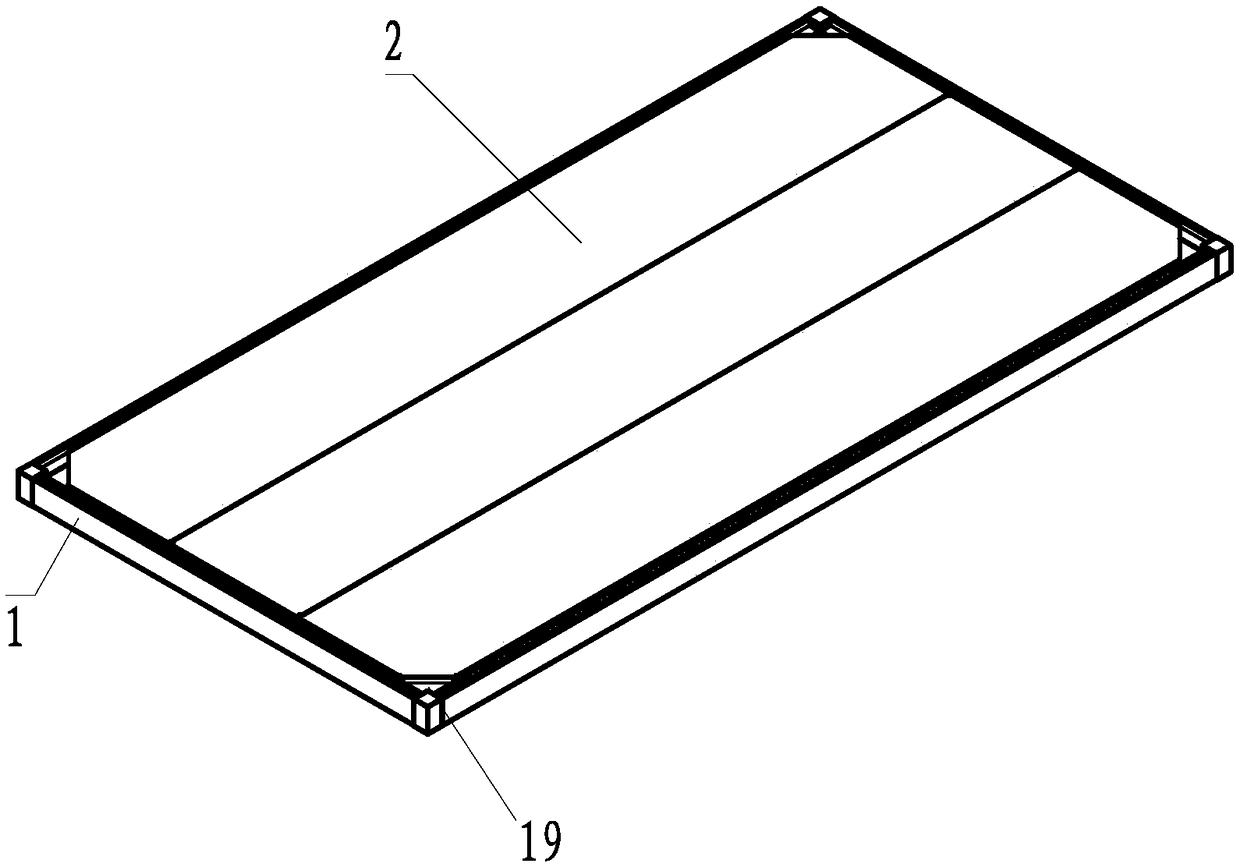

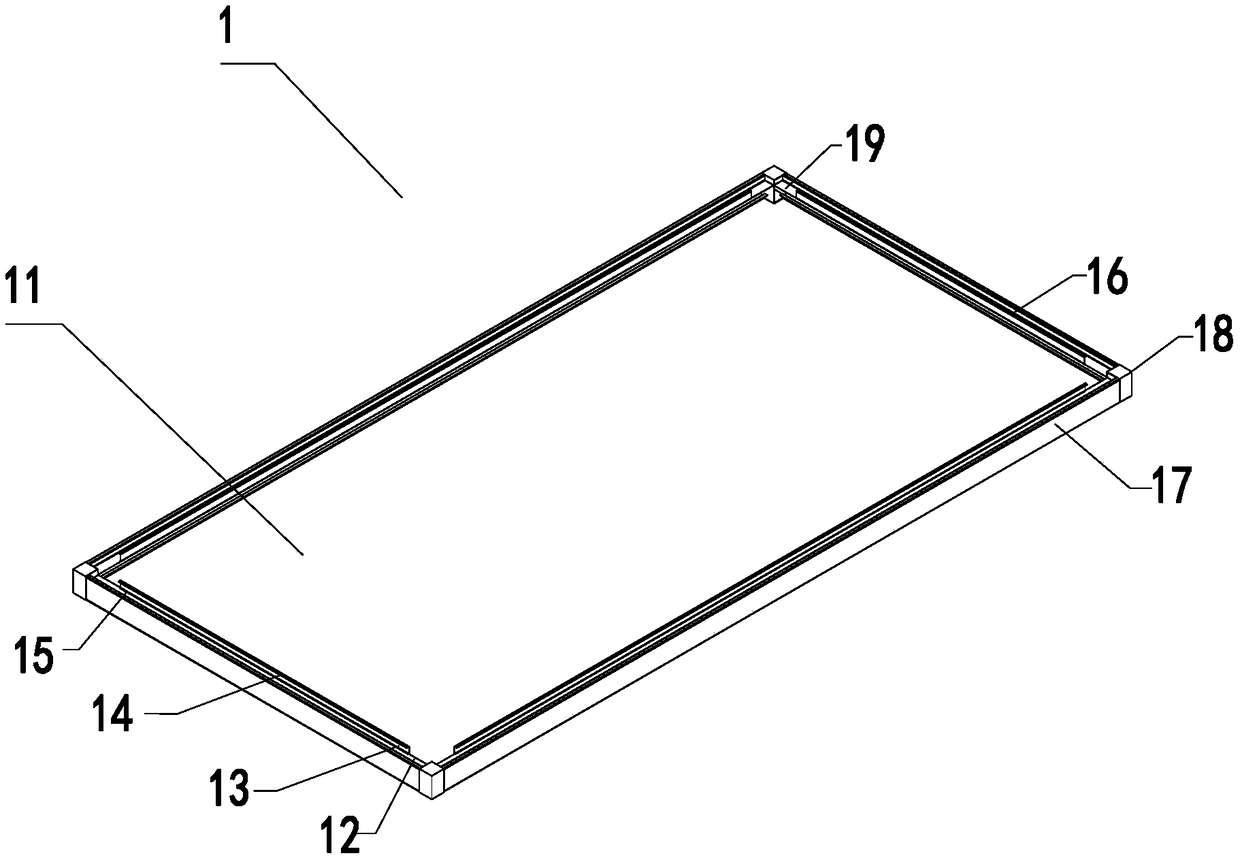

[0030] refer to Figure 1-4 , a residential container roof structure, comprising: a frame 1 and a roof 2; the frame 1 forms a rectangular accommodation space 11;

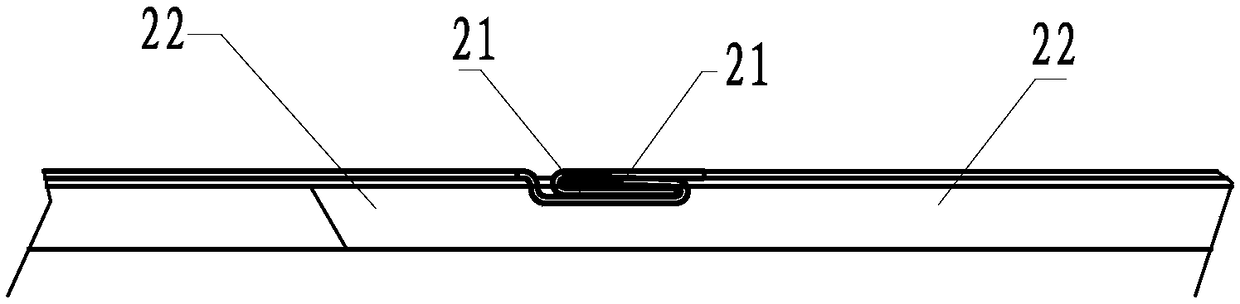

[0031] The outer periphery of the frame 1 is a ring enclosure, and a platform 12 is horizontally extended inwardly from the side of the enclosure towards the accommodation space; a surrounding edge 13 extends vertically upward from the free end of the platform 12; A skirt 14 extends horizontally from the free end of the edge 13 toward the direction away from the accommodating space 11 ; an accommodating groove 15 is formed between the surrounding edge 13 and a side of the enclosure facing the accommodating space.

[0032] In this embodiment, the frame 1 includes a cross bar 16 , a vertical bar 17 and a corner connector 18 for connecting the cross bar 16 and the vertical bar 17 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com