Method for determining waterway dredging mud dumping time period on basis of sediment loss rate minimum criterion

A technology for channel dredging and time period, applied in the field of excavators or dredging machines, can solve problems such as experience and limitations alone, and achieve the effects of improving utilization rate, reducing adverse effects, improving operation efficiency and dredging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

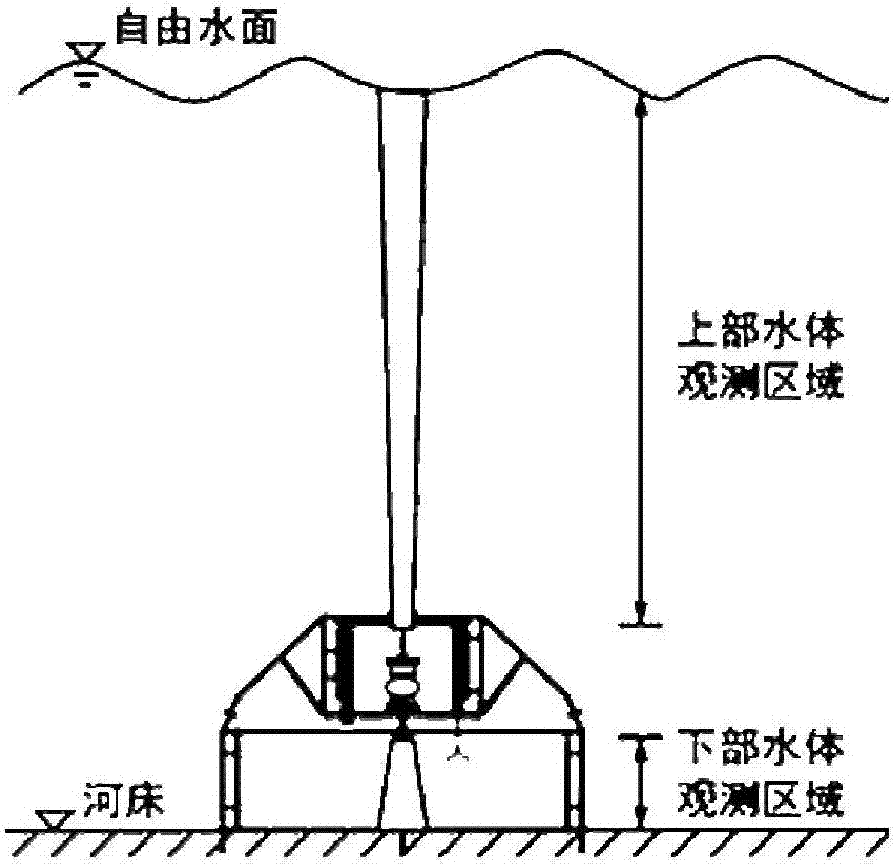

[0029] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

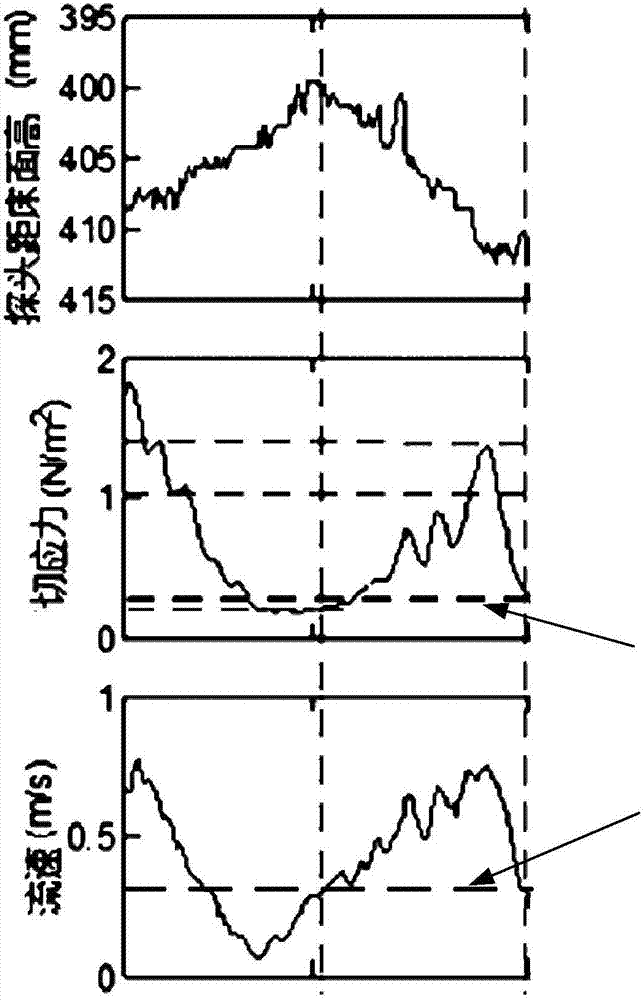

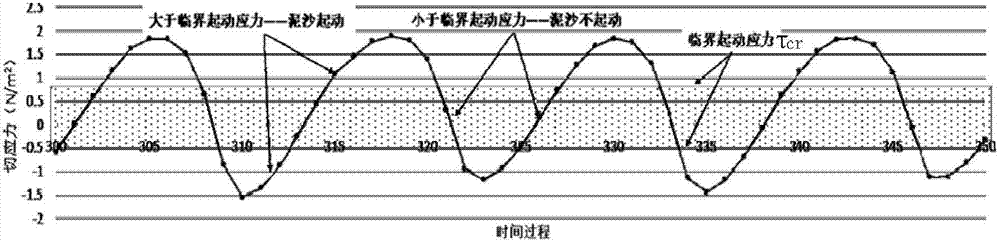

[0030] According to the minimum requirement of the sediment loss rate in the mud pit, the method for determining the mud throwing time period of the channel dredging ship under the tidal action of the present invention determines the mud throwing time period according to the minimum criterion of the mud loss rate:

[0031] It is necessary to reduce the sediment loss rate of the dump pit as much as possible and improve the utilization efficiency of the dredged soil. This criterion determines the mud throwing time period according to the hydrodynamic value corresponding to the mud throwing moment, so as to ensure that the loss rate of dredged soil is as small as possible, and selects all the time periods when the shear stress (or flow velocity) of all water flow is less than the critical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com