Wire harness drawing and pulling shear device

A cutting device and wire harness technology, applied in the field of wire harness cutting, can solve the problems of inconvenient peeling processing, time-consuming and labor-intensive, inconsistent length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

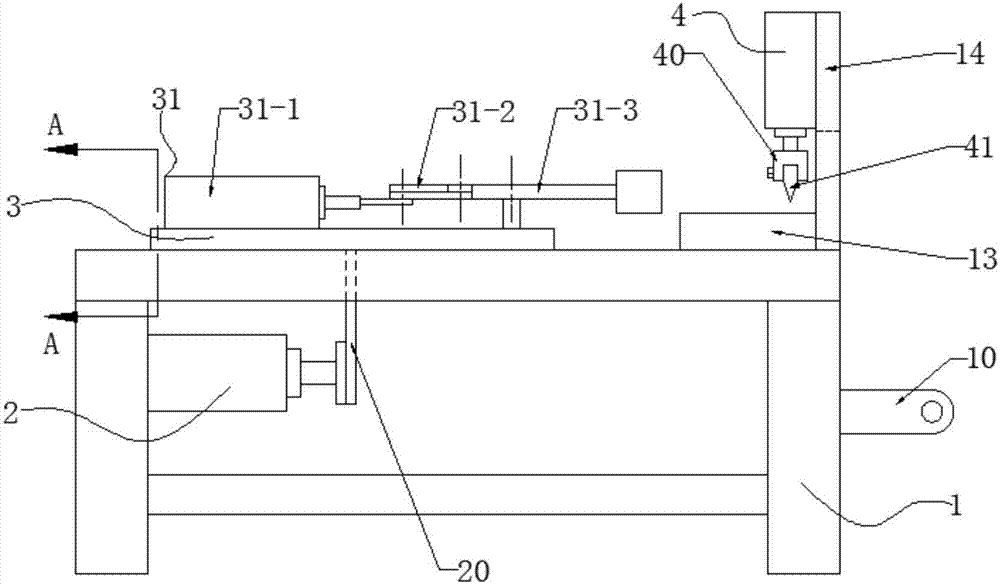

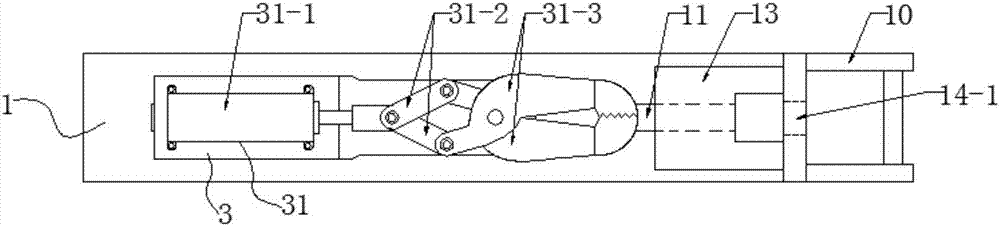

[0016] Such as Figure 1 to Figure 3 As shown, the present invention is a wire harness drawing and shearing device, which realizes the shearing operation of the coiled wire harness, ensures the uniformity of the length of the wire harness, and facilitates the subsequent binding operation.

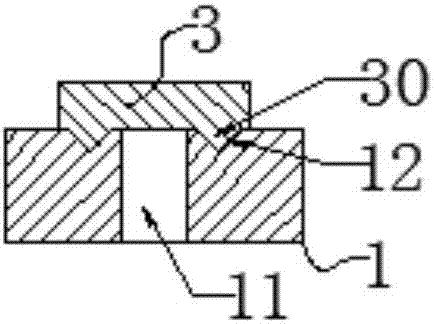

[0017] Specifically, if Figure 1 to Figure 3 As shown, including frame 1, cylinder one 2, slide table 3 and cylinder three 4, such as figure 1 , figure 2 As shown, the side of the frame 1 is provided with a winding hanger 10, and the middle of the upper end of the frame 1 is provided with a long groove 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com