Method and device for cutting dough input from extruder

A cutting device and dough technology, applied in the direction of dough forming and cutting equipment, etc., can solve problems such as difficult to immediately evaluate the effect of adjustment and modification, cumbersome discovery, blurred effect of adjustment and modification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

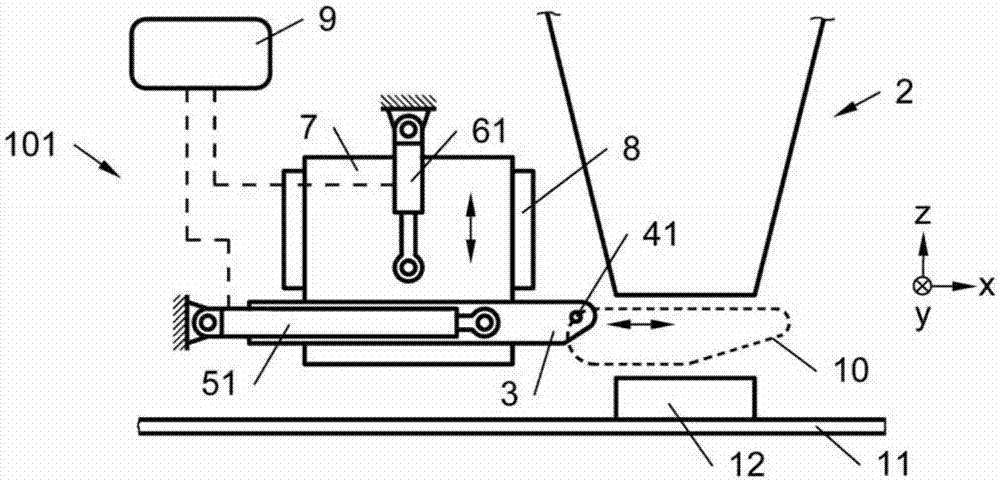

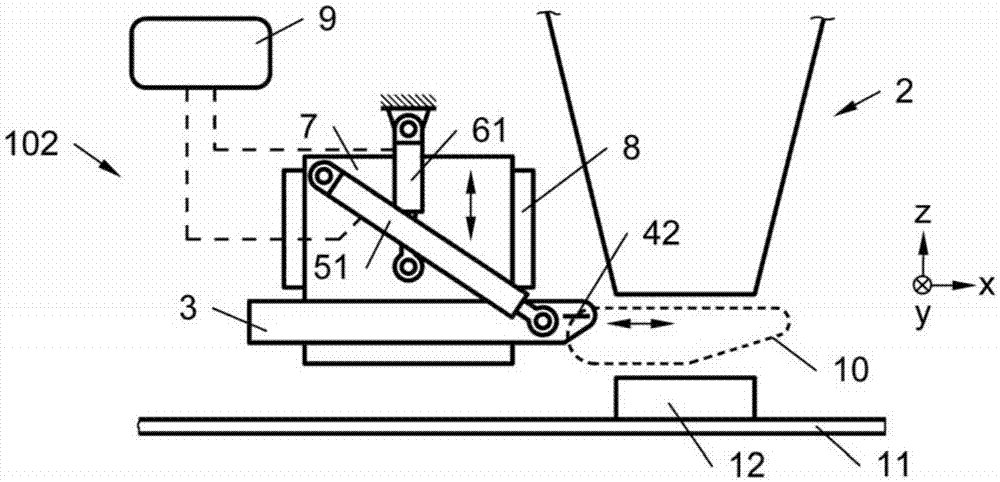

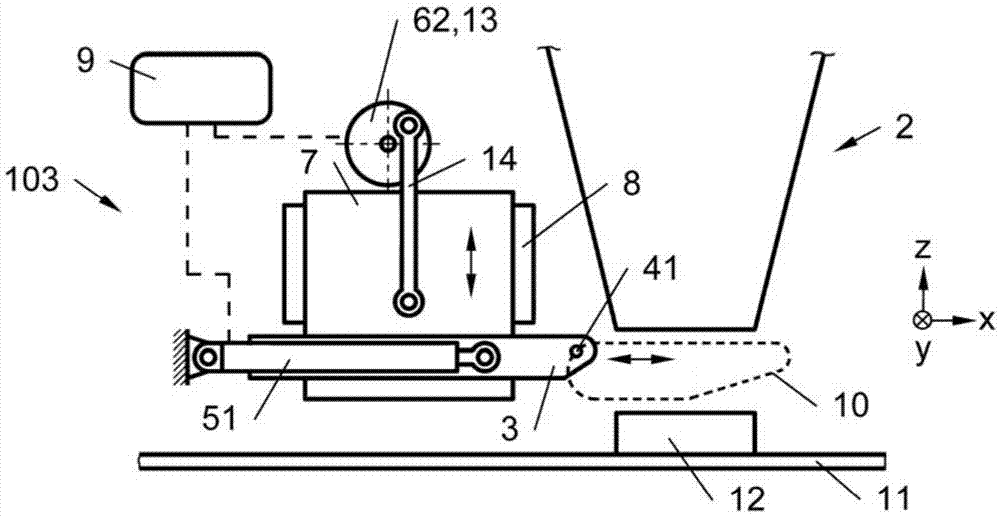

[0033] figure 1 A schematic side view of a first embodiment of the cutting device 101 of the noodle press 2 is shown. The cutting device 101 comprises a movable frame 3 on which the wire 41 is mounted and to which a first driver 51 is connected so as to move the frame 3 along a first direction x. Furthermore, the cutting device 101 comprises a second drive 61 connected to said frame 3, which moves the frame 3 along a second direction z transverse to said first direction x. The second driver 61 may be driven independently of the first driver 51 .

[0034] In this embodiment, the frame 3 is mounted on a carriage 7 by means of a first linear track or guide oriented in a first direction x, and by means of a second linear track or guide oriented in a second direction z, said carriage 7 It is installed on the base 8. Thus, the carriage 7 can move in the vertical direction z, and the frame 3 can move in the horizontal direction x and the vertical direction z. However, in an alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com