High-altitude cable

A high-altitude cable and cable technology, which is applied in the direction of insulated cables, power cables, and power cables for overhead applications, etc., can solve the problems of inconvenient replacement and maintenance of high-altitude cables, shortened service life of cables, and large current and voltage. The effect of breaking capacity, improving service life, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

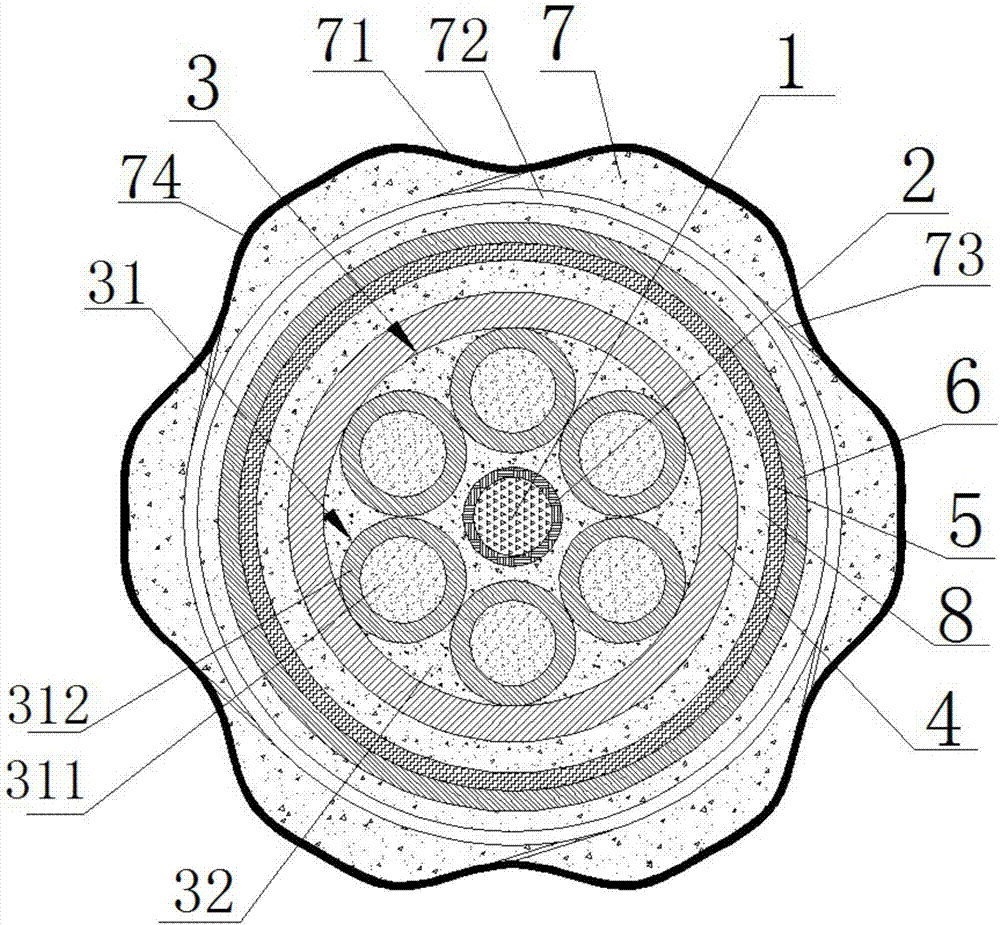

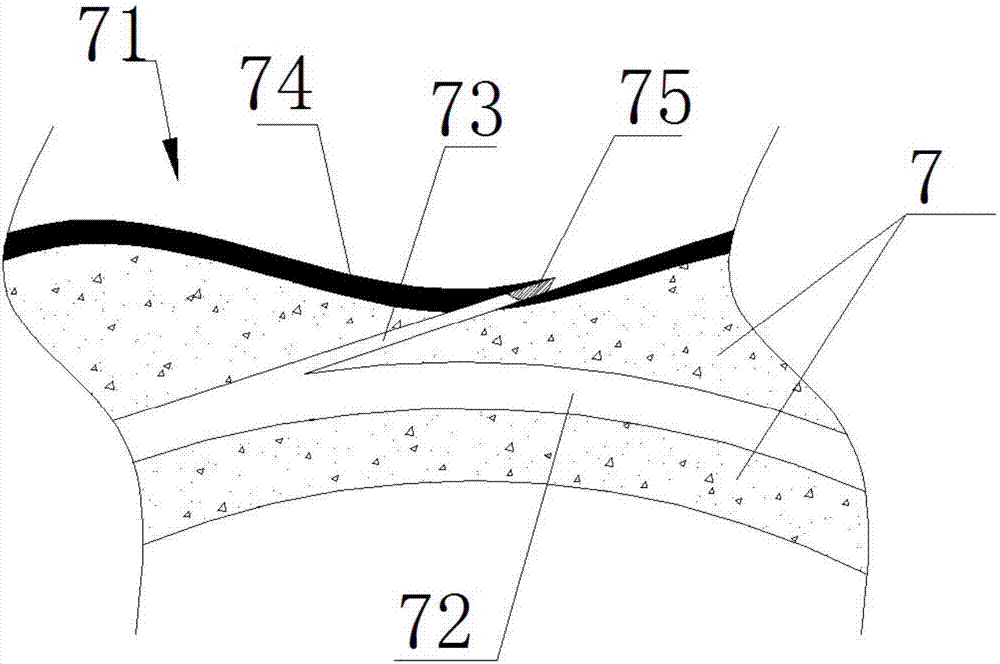

[0032] Such as figure 1 As shown, a high-altitude cable includes an oil-absorbing layer 1 and a fireproof layer 2, a core layer 3, an insulating layer 4, a first heat-conducting layer 8, a shielding layer 5, and a waterproof layer 6 and the second heat conducting layer 7; the oil absorbing layer 1 is adsorbed with insulating heat conducting fluid, which not only can effectively absorb heat for the cable, but also the oil absorbing layer 1 has flexibility, which can improve the overall breaking resistance of the cable; the wire core Layer 3 includes electric wires 31 distributed in a circular shape along the radial section of the cable and heat-conducting materials 32 filled in the gaps between the electric wires 31. The electric wires 31 have a uniform layout, high structural strength, and good heat dissipation effect; the electric wires 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com