Specific gravity measuring bench and operation method thereof

An operation method and technology of measuring racks, applied in the field of specific gravity measuring racks, can solve the problems of danger of experimenters, slow measurement speed, easy to spill liquid, etc., and achieve the effects of high test efficiency, simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

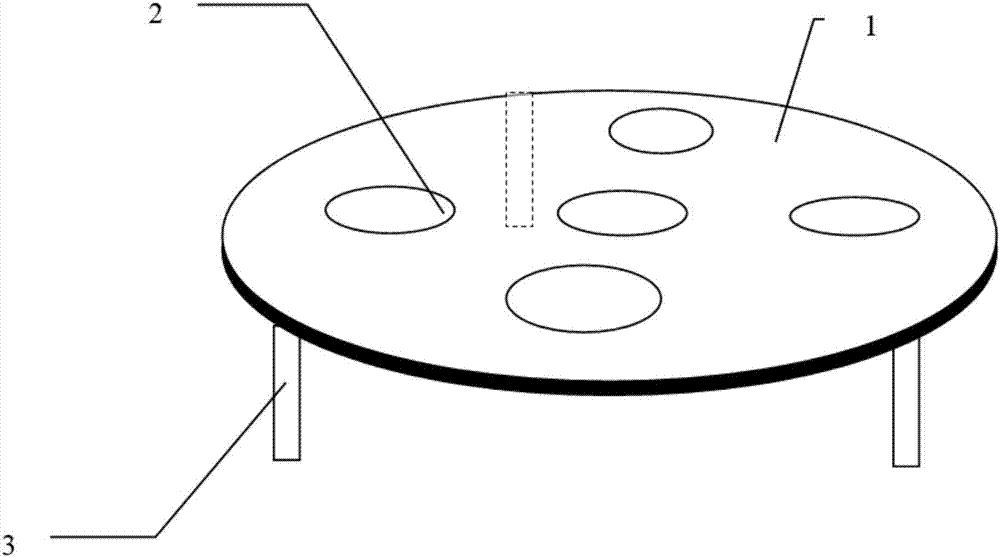

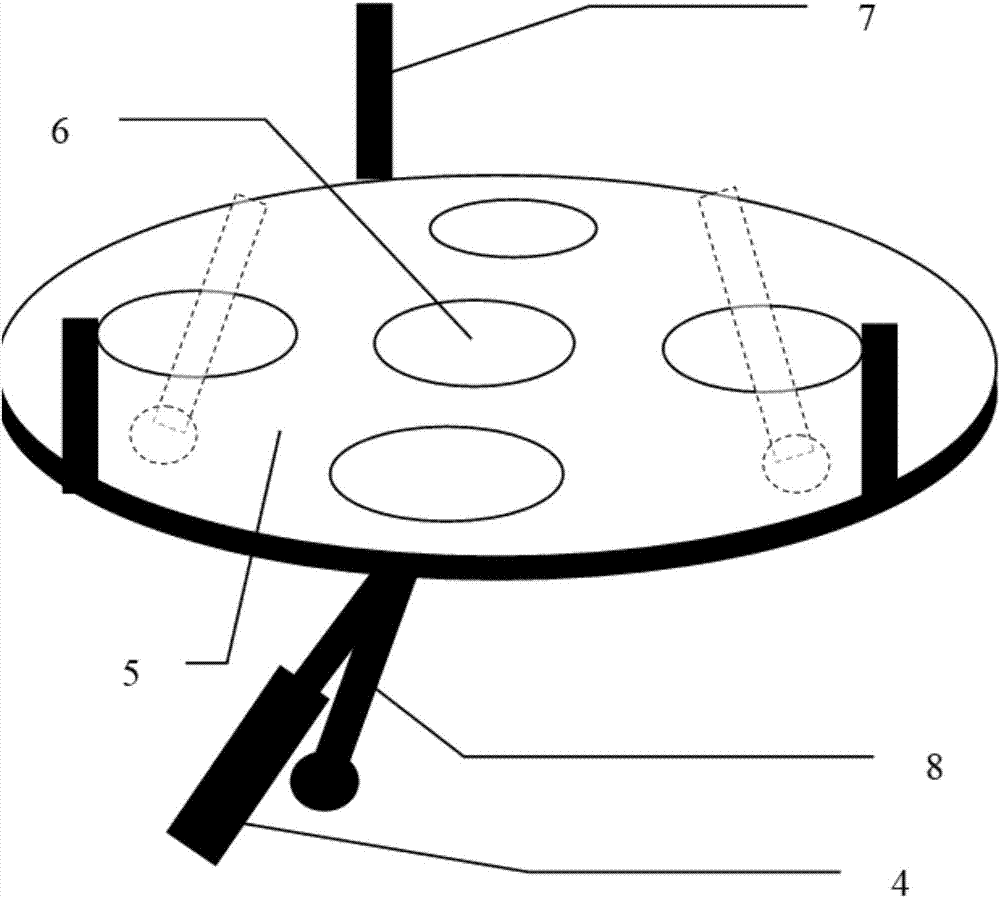

[0022] refer to figure 1 , figure 2 , a specific gravity measuring frame, mainly composed of two parts, an upper frame body 1 and a lower frame body 5, said upper frame body 1 is provided with several fixed bottleneck openings 2 and three fixed frame sleeves 3, and the fixed frame sleeves 3 are In order to be placed on the solid frame pipe 7 on the lower frame body 5, to fix the upper frame body 1 and the lower frame body 5, to keep it stable, any of the three solid frame real pipes 7 on the upper frame body 1 A rocking bar 4 is provided on the opposite side of the real pipe 7 of a solid frame, and the rocking bar 4 can shake the whole specific gravity measuring frame up and down; The frame body 5 is also provided with three solid frame real pipes 7, the positions of the three solid frame real tubes 7 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com