Asphalt concrete surface layer and construction method thereof

A kind of asphalt concrete and surface layer technology, which is applied to the cohesive pavement paved on site, buildings, roads, etc., can solve the problems of decreased ice-breaking ability, poor wear resistance, and poor elastic effect, so as to reduce wear and avoid cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

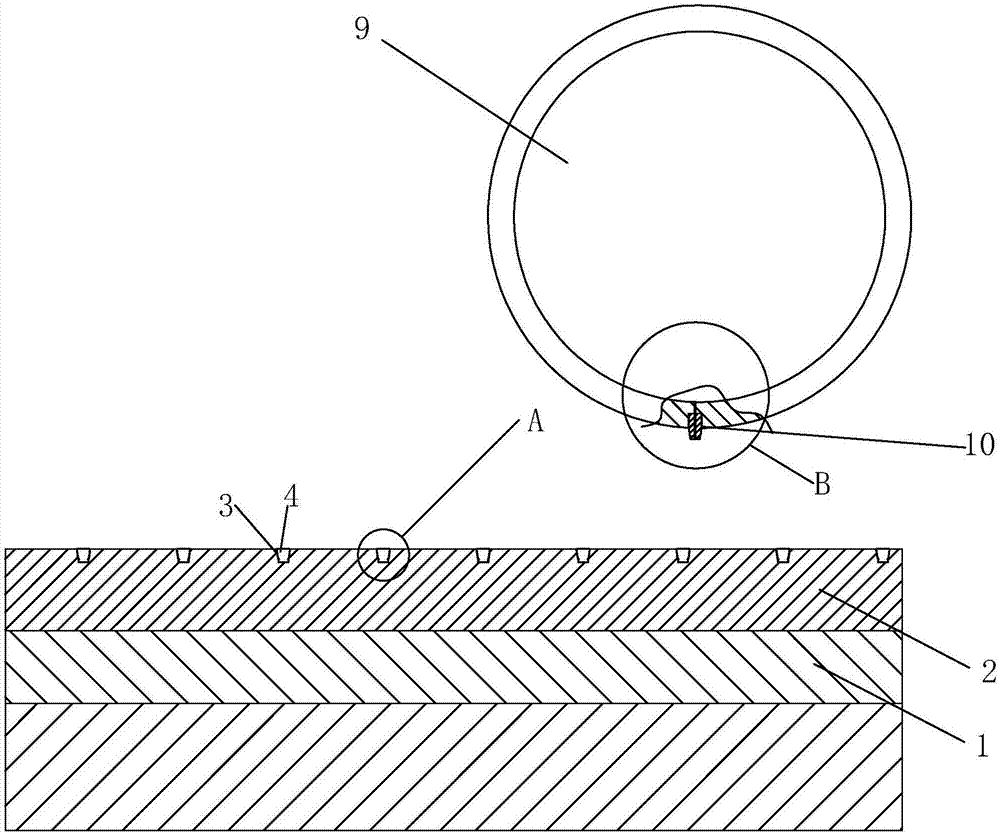

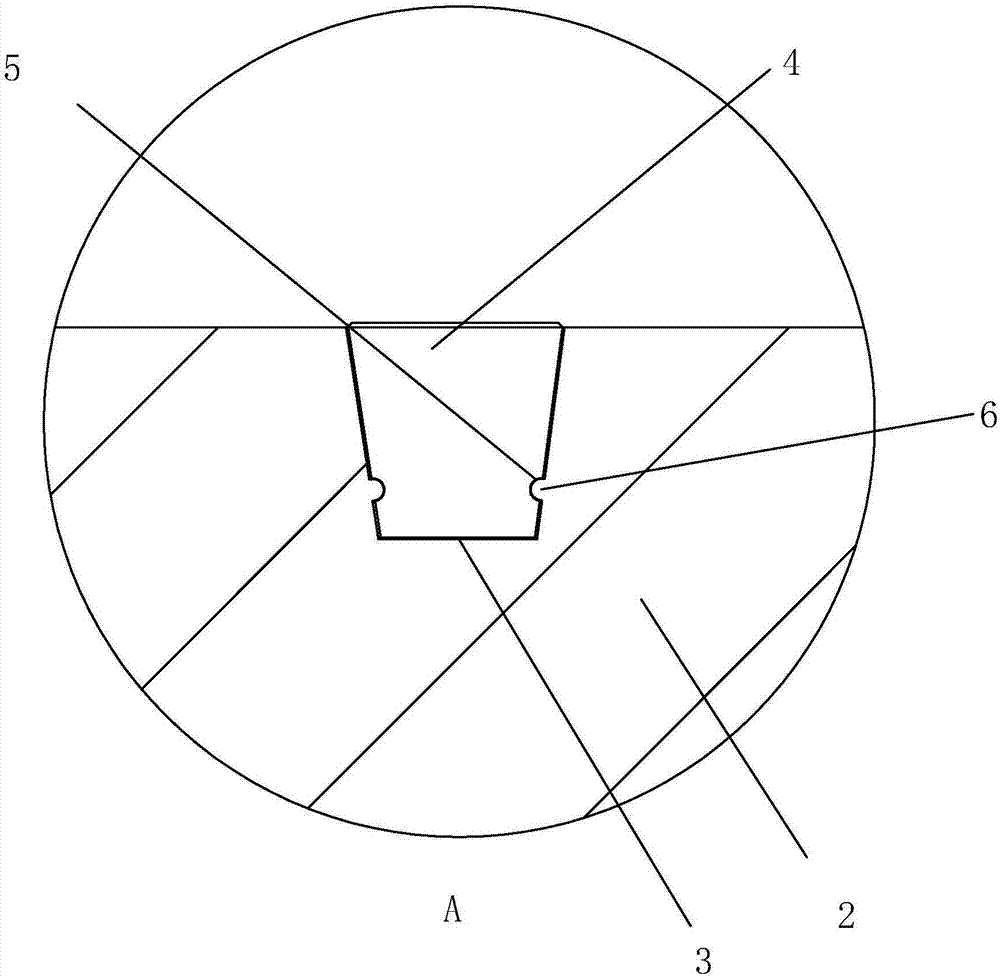

[0033] Embodiment 1: as figure 1 Shown, a kind of bituminous concrete surface course, comprises the leveling course 1 that is arranged on the soil, and leveling course 1 is made of crushed stone and yellow sand, plays the effect of leveling soil, spreads on leveling course 1 and The asphalt concrete base 2 is compacted, and the asphalt concrete base 2 is used as the surface of a high-speed or elevated driveway. The two sides of each lane of the asphalt concrete base 2 are provided with a truncated conical deformation groove 3, and each deformation groove 3 is along the length direction of the driveway. There is one on each side of the meter.

[0034] Such as figure 2 As shown, the depth of the deformation groove 3 is 1.8-2.8 centimeters, the diameter of the upper end of the deformation groove 3 is 2-3 centimeters, and the diameter of the lower end of the deformation groove 3 is less than the diameter of the upper end 0.5-1 centimeter, that is, the longitudinal section shape ...

Embodiment 2

[0037] A construction technique applied to embodiment 1, comprising the following steps:

[0038] Step 1, laying a leveling layer 1 on the roadbed, the thickness of the leveling layer 1 is 5 cm;

[0039] Step 2, laying asphalt concrete on the leveling layer 1 by a paver, and the laying thickness is 3 cm;

[0040] Step 3: Pre-compact the paved asphalt concrete with a road roller at a rolling speed of 15 meters per minute;

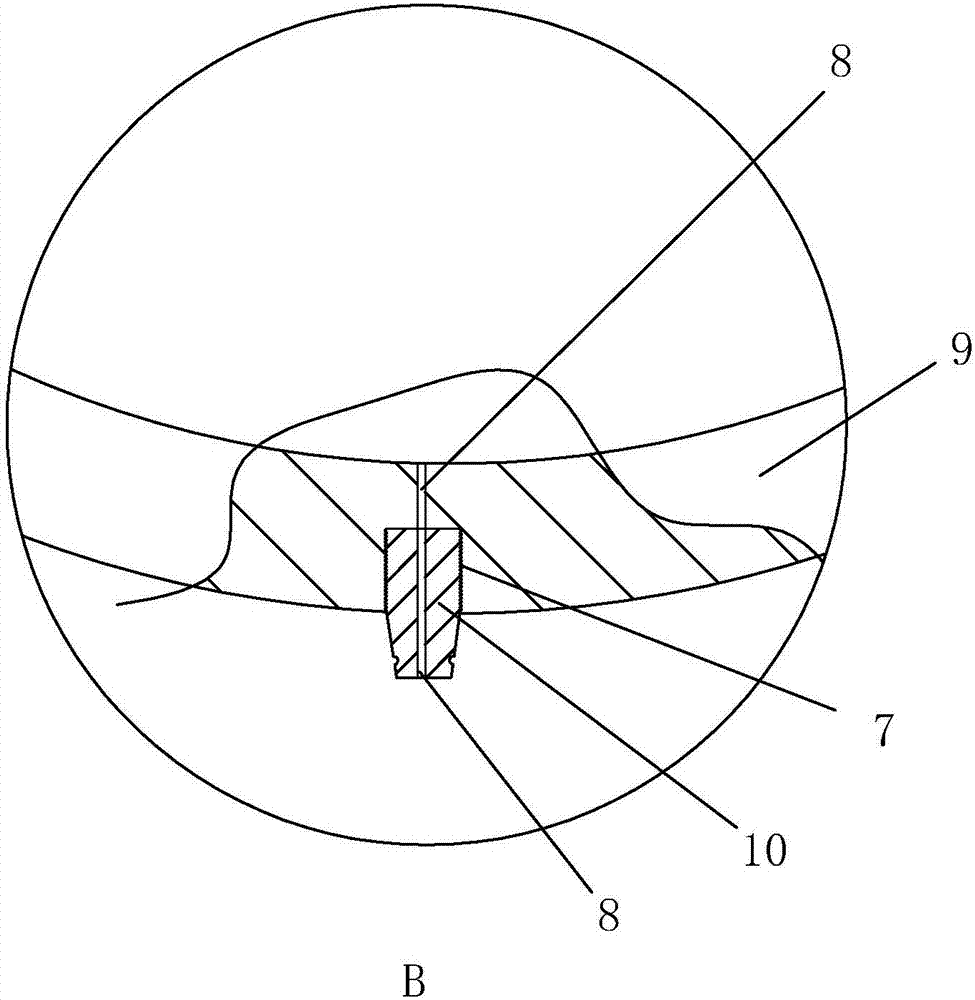

[0041] Step 4, the rolling block 10 corresponding to the size of the deformation groove 3 is installed on the circumferential surface of the rolling wheel 9 of the road roller corresponding to the position on both sides of the roadway, and the pre-compacted asphalt concrete layer is compacted by the road roller; The speed is 12 meters per minute;

[0042] Step 5. When the temperature of the asphalt concrete is lower than 30 degrees, manually inject molten modified rubber into the deformation tank 3 and protrude from the surface of the asphalt concrete base...

Embodiment 3

[0044] A construction technique applied to embodiment 1, comprising the following steps:

[0045] Step 1, laying a leveling layer 1 on the roadbed, the thickness of the leveling layer 1 is 10 cm;

[0046] Step 2, lay asphalt concrete on the leveling layer 1 by a paver, and the laying thickness is 7 cm;

[0047] Step 3. Pre-compact the paved asphalt concrete with a road roller at a rolling speed of 20 meters per minute;

[0048] Step 4, the rolling block 10 corresponding to the size of the deformation groove 3 is installed on the circumferential surface of the rolling wheel 9 of the road roller corresponding to the position on both sides of the roadway, and the pre-compacted asphalt concrete layer is compacted by the road roller; The speed is 16 meters per minute, such as image 3As shown, the surface of the rolling wheel 9 is provided with a threaded hole 7, and the bottom of the rolling block 10 is provided with an external thread that cooperates with the threaded hole 7. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com