Coating device for plastic plate

A technology for plastic plates and coatings, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of uneven oil, sticky plastic oil, trouble, etc., to reduce labor intensity, avoid delamination, paint Layer uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

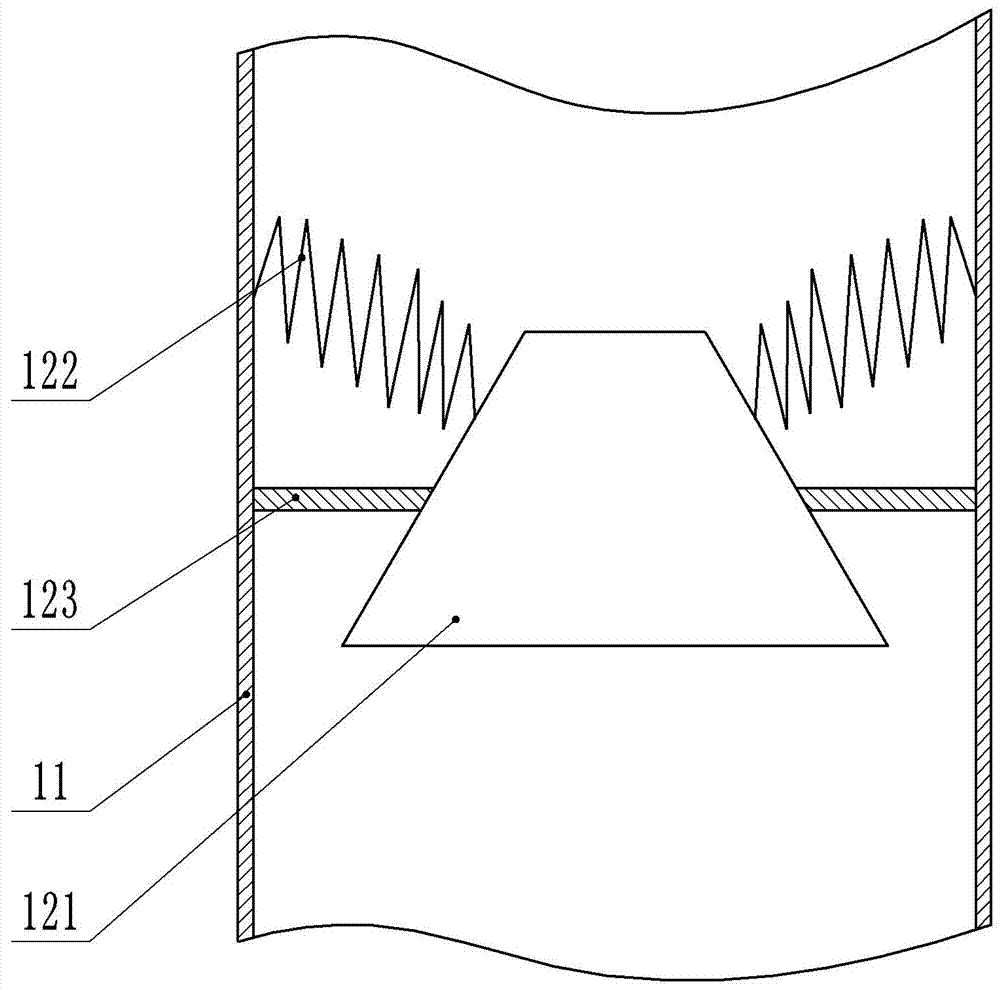

[0025] Such as figure 1 , figure 2 As shown, the coating device for plastic boards includes a frame, a liquid tank 1 and a motor. The frame is provided with a lower coating roller 3 and a height-adjustable upper coating roller 5, and the lower part of the lower coating roller 3 is located in the liquid tank. Inside Pool 1. The motor is used to drive the lower coating roller 3 and the upper coating roller 5, and when the motor is started, the lower coating roller 3 and the upper coating roller 5 can rotate. The lower auxiliary roller 4 and the upper auxiliary roller 6 arranged as a truncated cone are installed on the frame, and the taper of the upper auxiliary roller 6 is 15-30 degrees, which is set to 20 degrees in this embodiment; Used in conjunction, and the lower auxiliary roller 4 cooperates with the lower coating roller 3. The frame is also provided with a liquid storage tank 7, which is used to supply plastic-absorbing oil for the upper auxiliary roller 6. The botto...

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 is that the coating device for plastic plates is provided with oil discharge pipe 13 instead of oil outlet pipe 11 and flow automatic regulating valve 12, and one end of oil discharge pipe 13 communicates with the upper part of liquid storage tank 7, The other end is located above the liquid storage pool 1, such as Figure 4 shown. By arranging the oil discharge pipe 13, the oil quantity in the liquid storage tank 7 can be kept in dynamic balance, so as to avoid overflowing of plastic-absorbing oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com