Single-driving type pure rotating and micro-positioning platform

A micro-positioning platform, pure rotation technology, applied to the parts of the instrument, instruments and other directions, can solve the problems of unfavorable rotation direction precision control, increase the complexity of motion control, different output characteristics of piezoelectric ceramics, etc., to achieve large rotation angle, The effect of simple control and high rotational accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

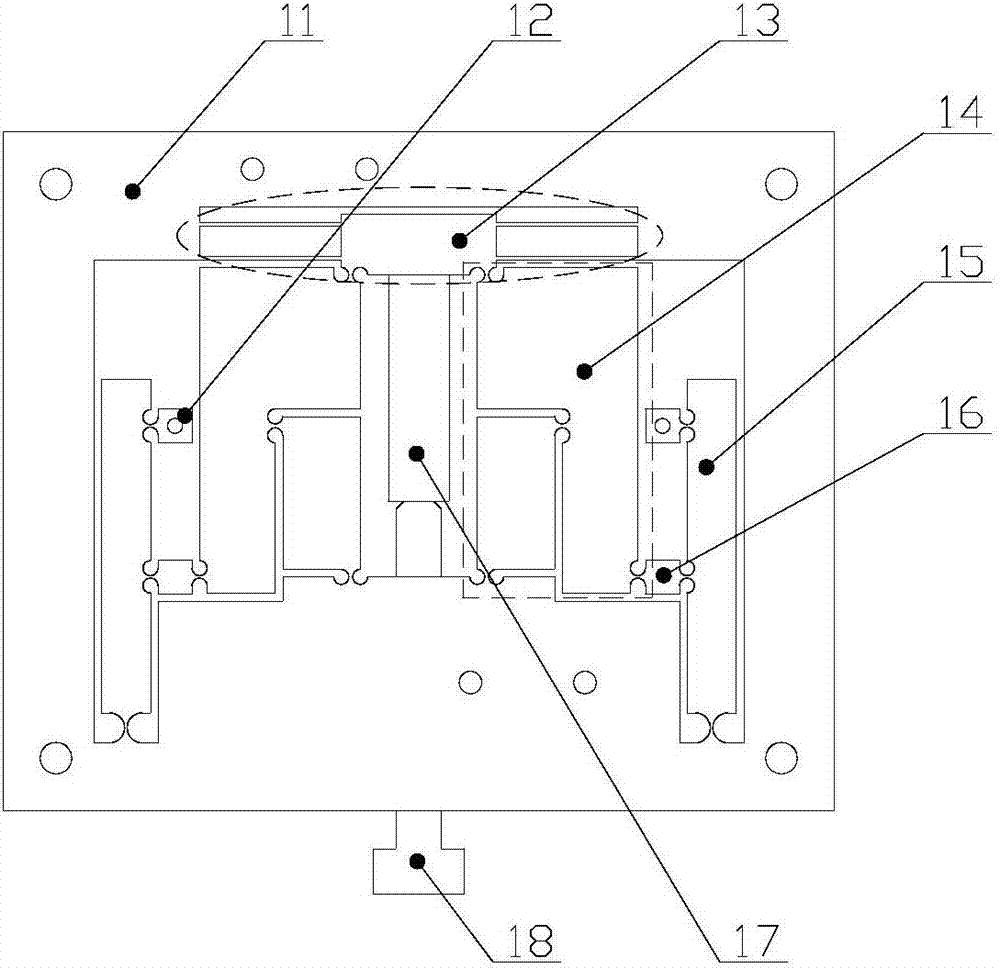

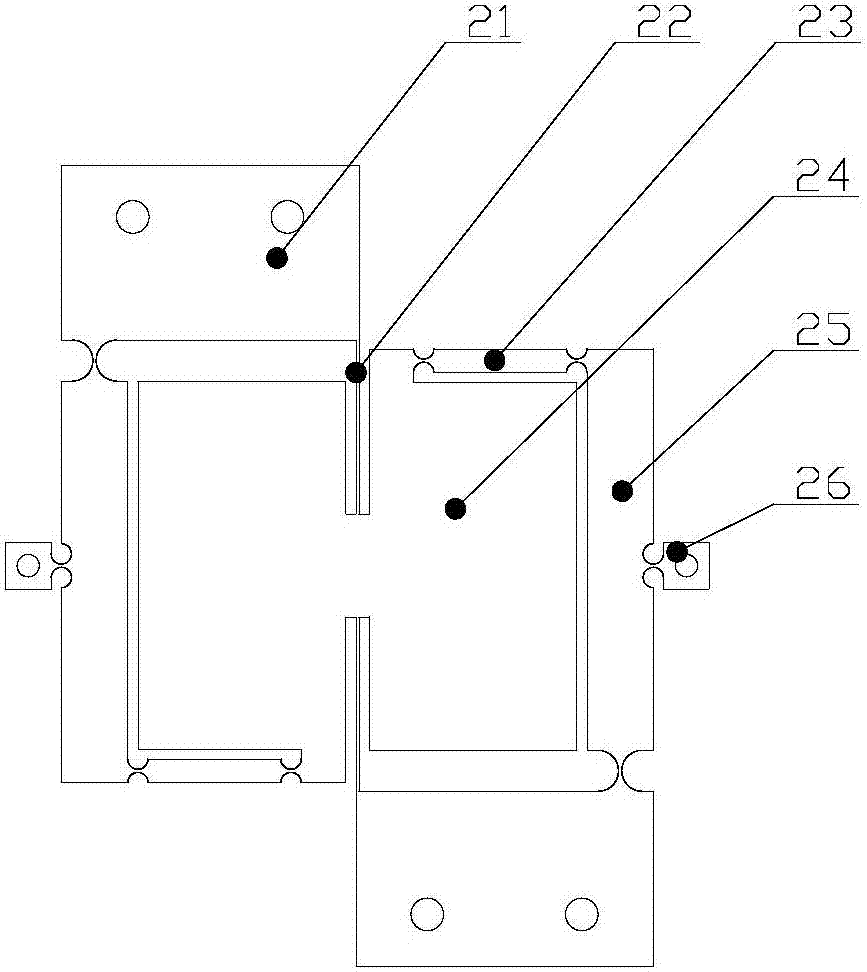

[0014] see Figure 1 ~ Figure 3 , a single-drive pure rotation micro-positioning platform, including an active drive mechanism 1 and a passive compliance mechanism 2 .

[0015] The active drive mechanism adopts a left-right symmetrical structure, including a base I11 and a guide mechanism 13 formed inside it. The left and right ends of the guide mechanism 13 are respectively provided with an output end, and a bottom of the guide mechanism 13 is provided. Piezoelectric ceramics 17 are provided with pre-tightening bolts 18 below the piezoelectric ceramics 17, and the two output ends of the guide mechanism 13 are respectively connected with the input ends of a vertical reversing amplifying mechanism 14, and the vertical reversing amplifying mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com