Thermal resistance tester for coating and testing method

A tester and paint technology, which is applied in the paint thermal resistance tester and testing field, can solve the problems that the heat transfer coefficient λ measurement is not easy to realize, the measurement device has relatively high precision requirements, and the paint coating thickness d is not easy to determine, etc., to achieve Improve test accuracy, low cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments. In these drawings, the size and relative sizes of layers and regions may be exaggerated for clarity.

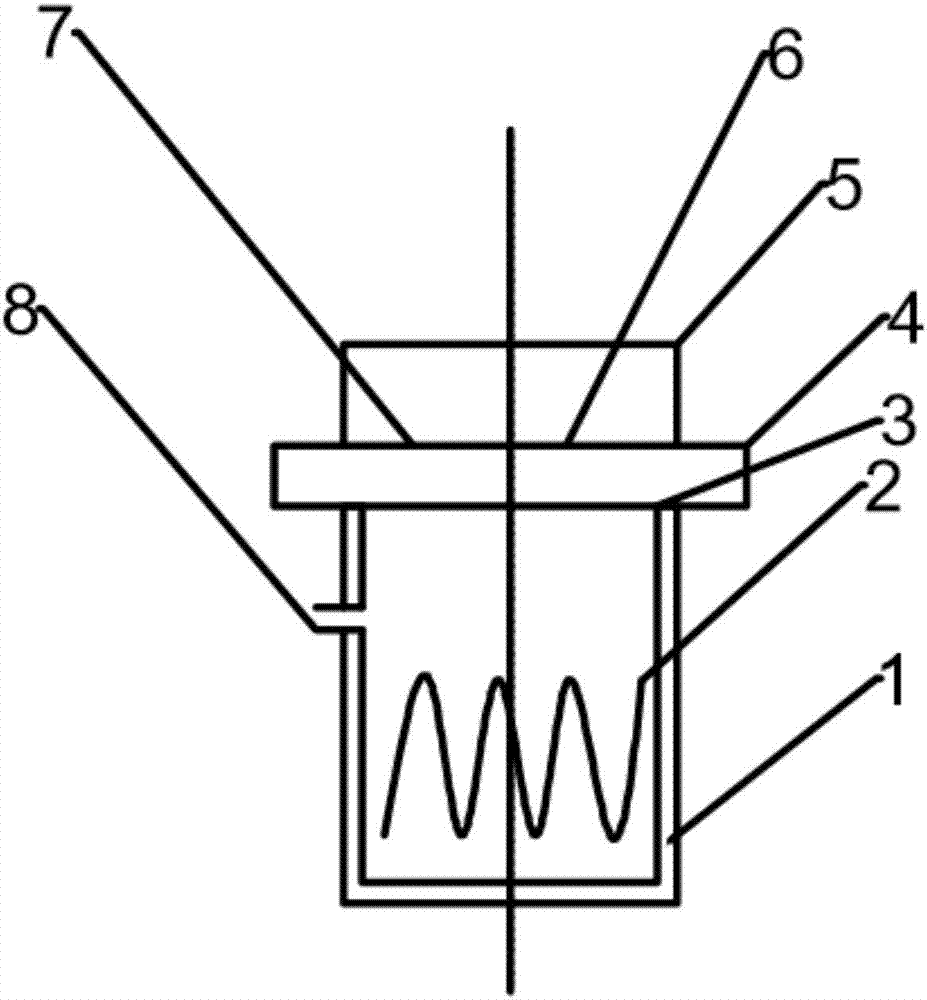

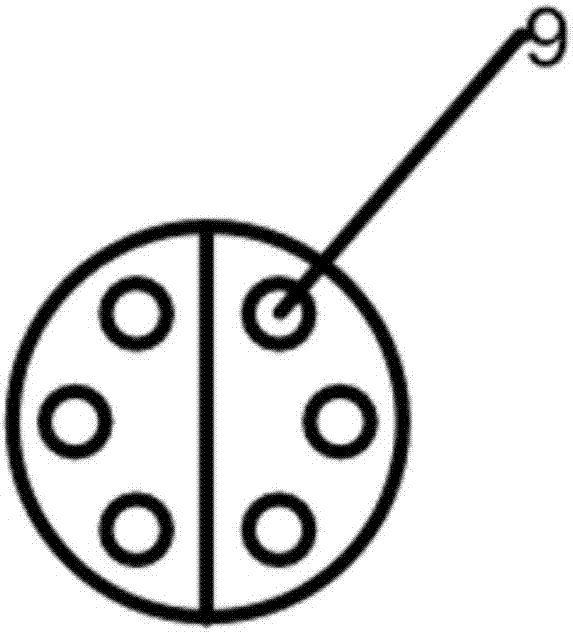

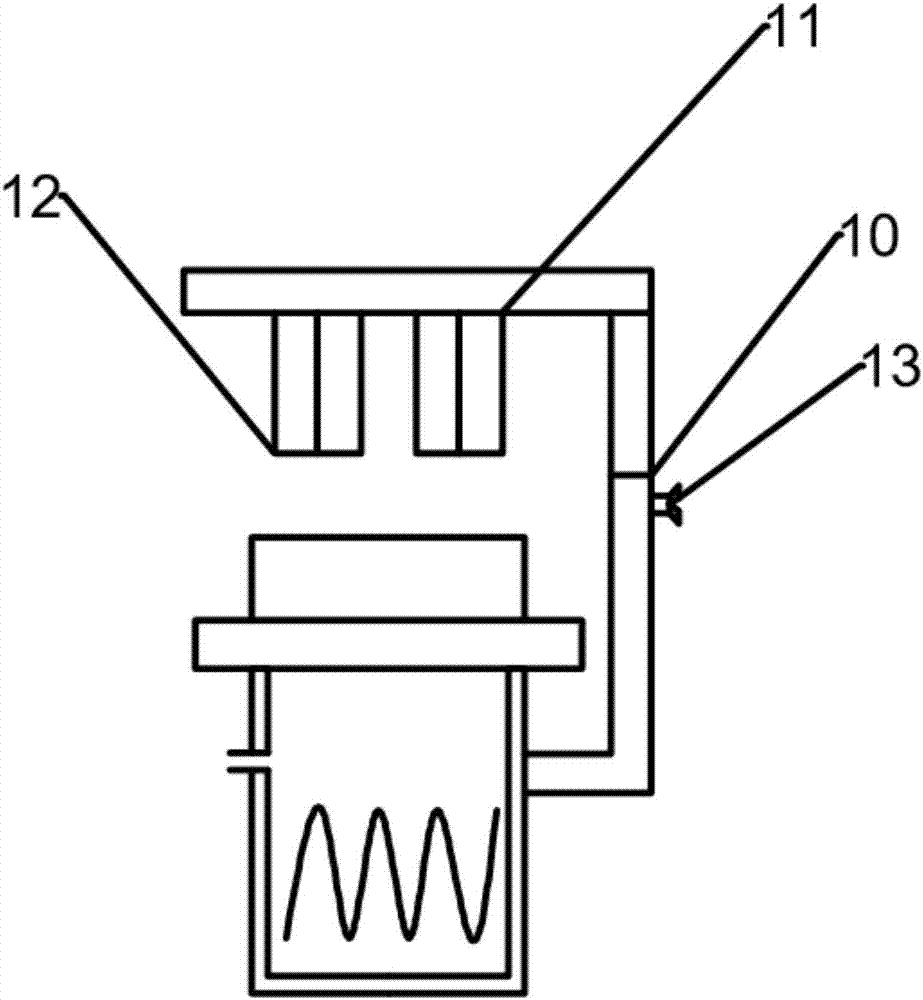

[0038] Such as Figure 1~3 As shown, a paint thermal resistance tester is tested by coating the paint to be tested on a thermally conductive material to form a test piece 4. The tester includes: a main body heating cup for heating the test piece 4 placed on it; Shaped temperature measurement auxiliary device 5, placed above the test piece 4, used to reduce the radiation heat transfer of the test piece 4 and the convective heat transfer with the air; the infrared temperature measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com