Continuous casting secondary cooling strand surface temperature contact measurement device

A technology of contact measurement and surface temperature, which is applied to the temperature measurement of moving fluid, the configuration of measuring devices, indicating equipment/measuring equipment, etc., to achieve the effect of simple and compact structure, high measurement accuracy and reducing the damage of temperature measuring head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

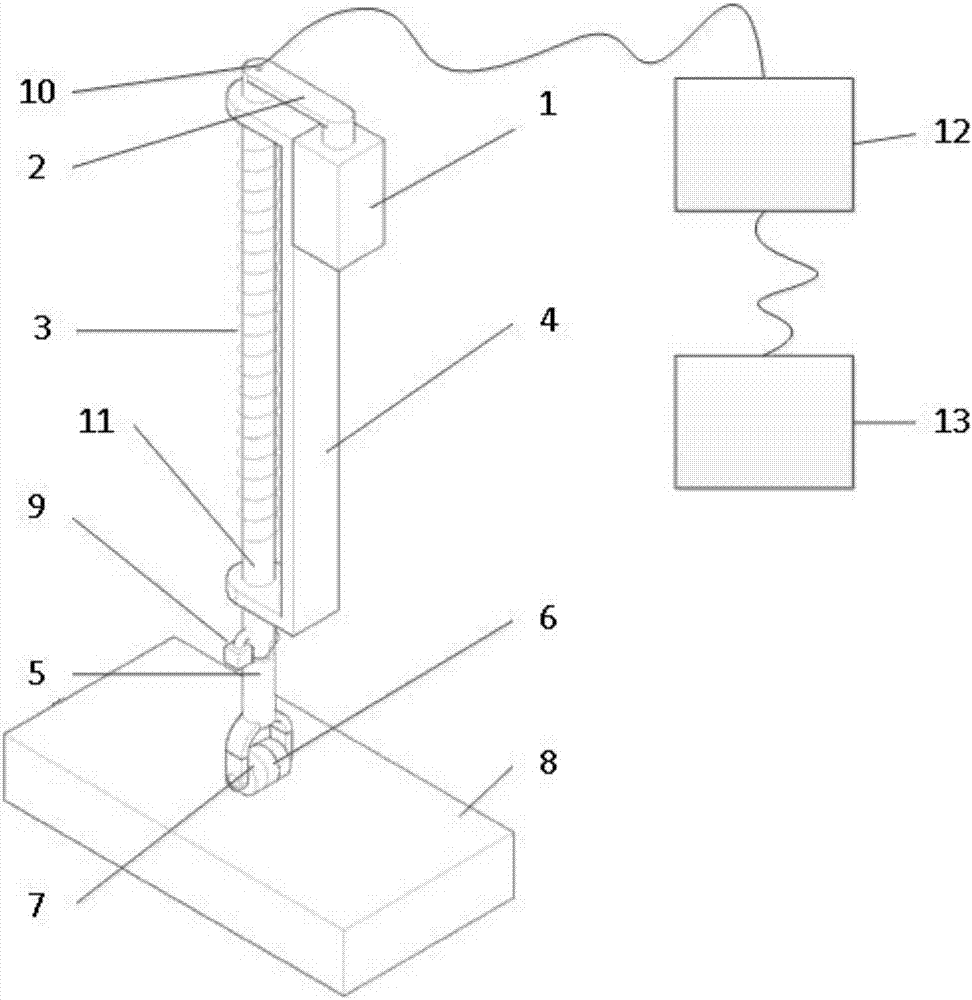

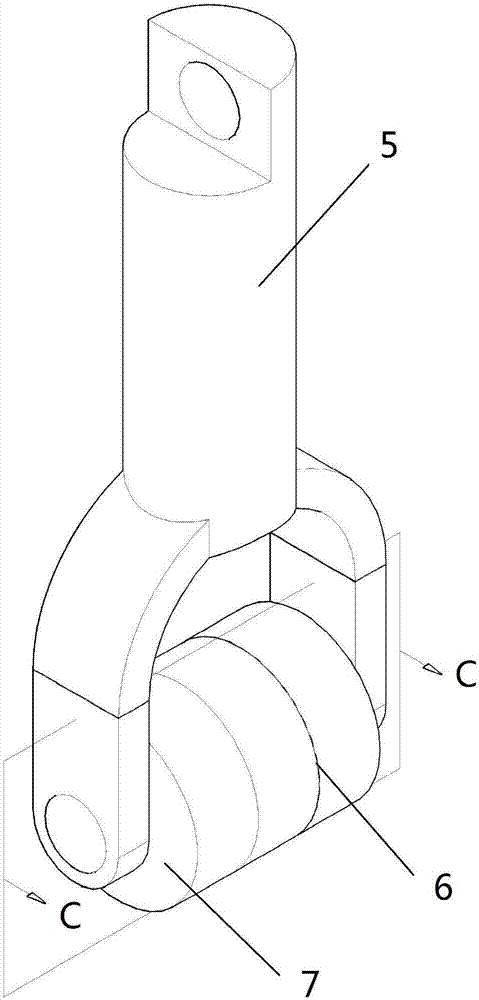

[0028] See Figure 1 to Figure 5 , the present invention provides a contact measuring device for the surface temperature of the continuous casting secondary cooling strand, which is installed between the continuous casting roll gaps and perpendicular to the surface of the slab; it includes a lifting cylinder 1, a cylinder connecting piece 2, a pressing spring 3 Bracket 4, anti-break back force node 5, temperature measuring head 6, roller 7, casting surface 8, rotary encoder 9, threading and cooling air inlet 10, temperature measuring rod 11, temperature signal processor 12 and computer 13.

[0029] The lifting cylinder 1 adopts a single-acting cylinder, installed on the bracket 4, and connected with the temperature measuring rod 11 through the cylinder connecting piece 2, and setting the temperature measuring head 6 or the anti-break back force node 5 through the computer 13 to trigger, so as to realize the same casting flow surface 8 contact and separation.

[0030] The down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com