Kitchen ventilator automatic control method based on capacitive transducer

A technology of capacitive sensor and range hood, which is applied in the field of lampblack emission, can solve problems such as the change of plate capacitance value, achieve the effect of ensuring the removal effect, reducing no-load power loss and noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

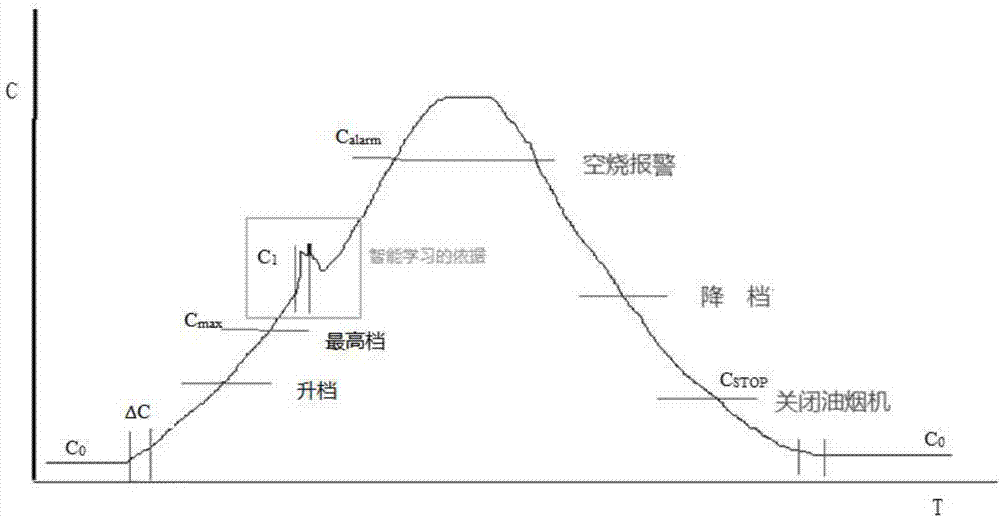

[0022] It can be seen from the prior art that the oil fume concentration and temperature change are directly proportional to the capacitance value of the capacitive sensor. The cooking steps unique to Chinese families are generally:

[0023] cooktop fire;

[0024] Heating the cooking oil, at this time, the oily fume is gradually generated, and the concentration of the oily fume is gradually increased;

[0025] Put the ingredients in the pot, and the concentration of oil fume will increase rapidly in a short time;

[0026] As the temperature of the ingredients gradually increases, the concentration of soot also gradually increases;

[0027] When the oil fume concentration reaches a certain value, it is in a stable state;

[0028] With the completion of food processing, the concentration of oil fume gradually decreases, and finally the oil fume completely dissipates.

[0029] The change of the oil fume concentration in the above cooking process is reflected by the relationsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com