Power failure brake

A brake, electric technology, applied in the direction of the brake type, brake parts, brake actuators, etc., can solve the problems of large volume and large heat generation of the brake frame and brake parts, so as to ensure the braking ability and ensure the The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

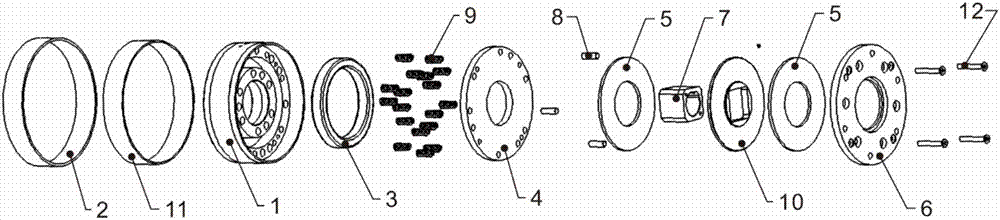

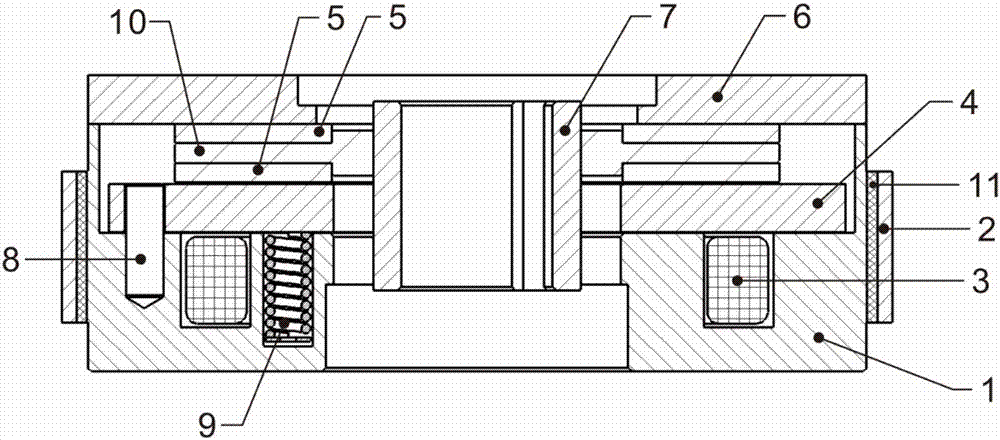

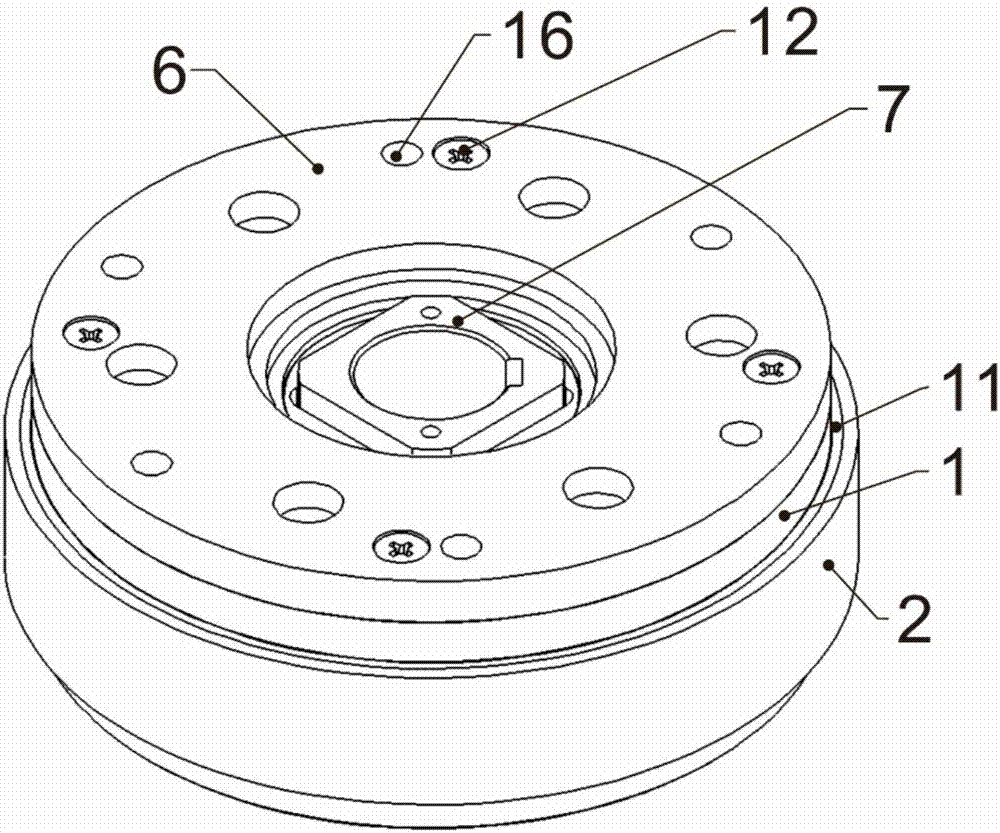

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0017] Such as Figure 1 to Figure 5 As shown, the de-energized brake includes a yoke 1 with a built-in coil slot 14, an excitation coil 3 is arranged in the coil slot 14, an armature 4 is placed on the inner end surface of the yoke 1, and a cover plate is connected to one end of the yoke 1 6. An intermediate body 10 connecting the transmission block 7 is provided between the cover plate 6 and the armature 4. The intermediate body 10 is made of iron, and the inner wall of the intermediate body 10 is closely matched with the transmission block 7. The intermediate body 10 Friction bodies 5 are provided at both ends, and the outer diameter of the friction body 5 is the same as that of the intermediate body 10. The inner end surface of the yoke 1 is provided with a plurality of spring seats 13 and spring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com