Centrifugal clutch

A technology of centrifugal clutches and dampers, applied in clutches, automatic clutches, mechanical equipment, etc., can solve problems such as difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

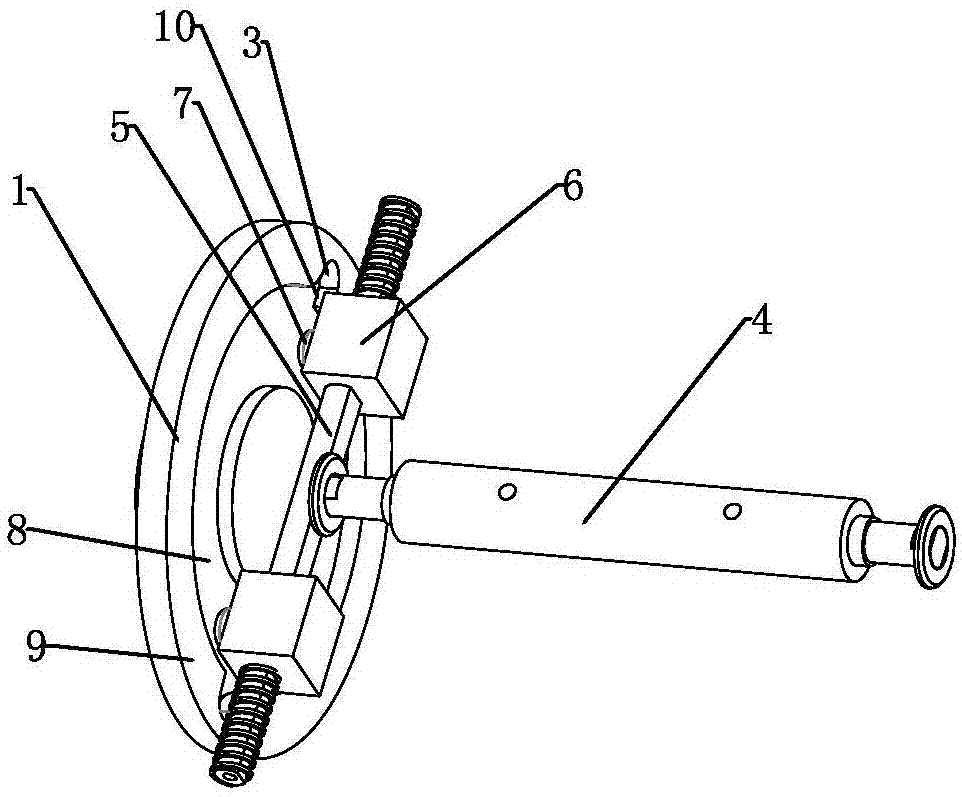

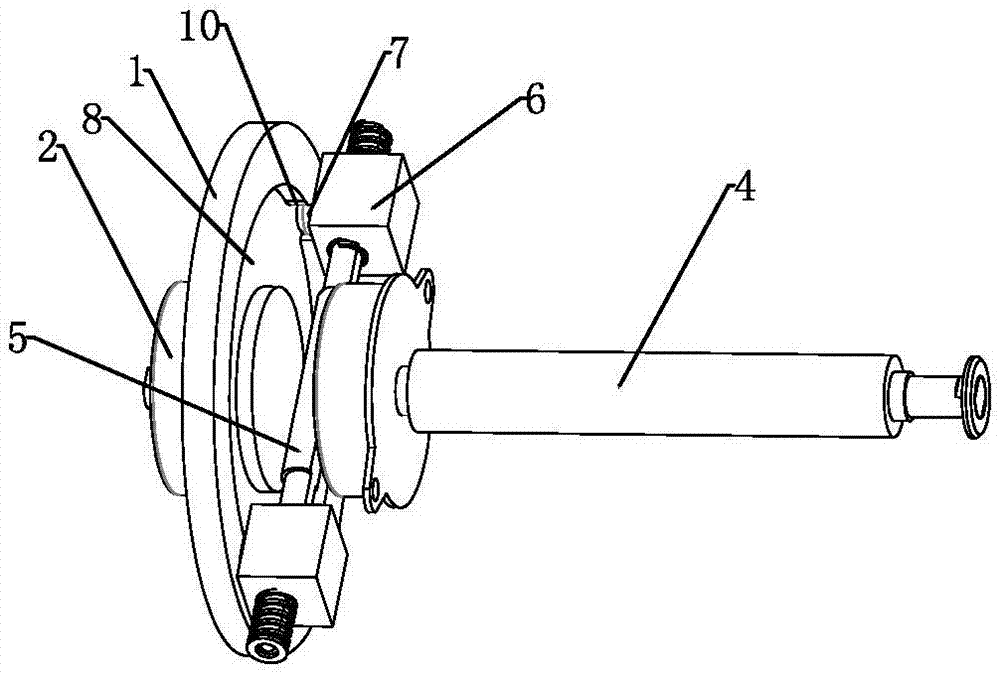

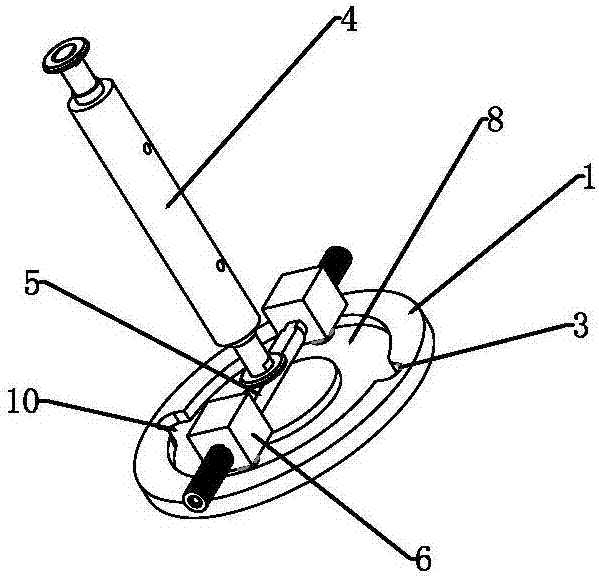

[0019] A centrifugal clutch as shown in the figure includes a driven shaft end plate 1 and a damper 2 arranged on the driven shaft end plate 1 . A slot 3 is provided on the end plate 1 of the driven shaft, a drive shaft 4 is provided on a surface opposite to the slot 3 , and a slide bar 5 is connected to one end of the drive shaft 4 . A counterweight 6 and a spring for restoring the counterweight 6 can be slid in the axial direction on the slide bar 5 , and a post 7 that can be snapped into the card slot 3 is provided on the counterweight 6 . In this case, the rotation of the driving shaft is used to drive the slide bar to rotate, and the counterweight is sleeved on the slide bar. When the slide bar is rotating, under the action of centrifugal force, the counterweight block will overcome the force of the return spring and slide out to the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com