a pulse gun

A pulse and detonator technology, applied in the field of pulse guns, can solve the problems of many explosion transmission links, long time-consuming, complex structure, etc., achieve the effect of isolating external high-temperature and high-pressure gas, reducing effective volume, and increasing work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

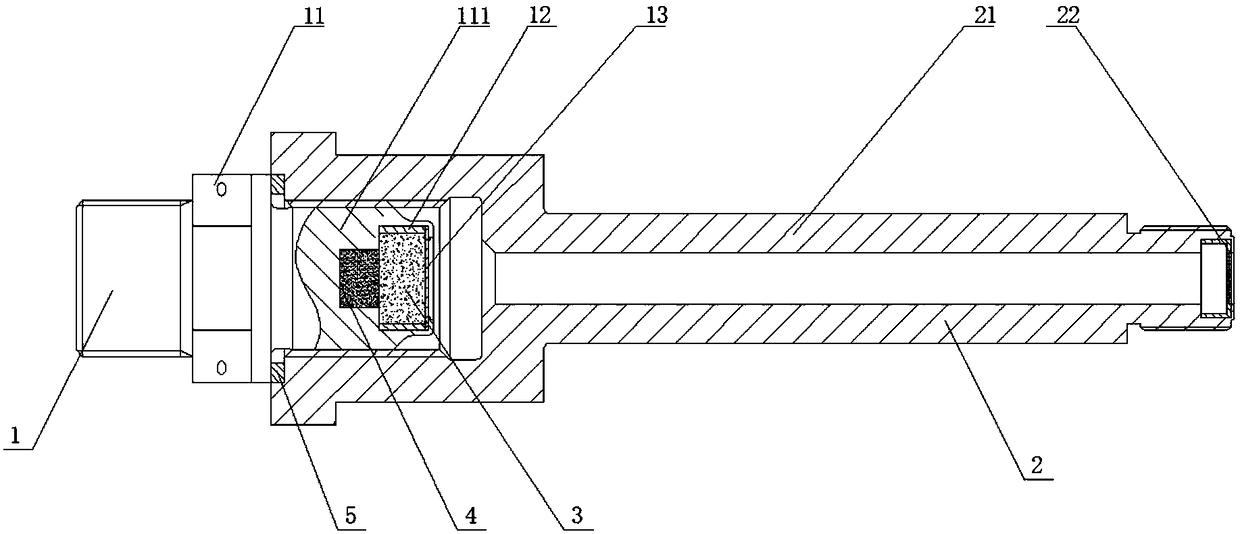

[0033] like figure 1 As shown, the pulse gun is composed of a detonating device 1 and a housing assembly 2 . The detonator 1 comprises a detonator body 11, a pressure ring 12 and a tablet 13; the input end of the detonator body 11 is connected with an excitation source, and the output end of the detonator body 11 is a boss 111, and the center of the boss 111 is provided with a stepped hole; the above-mentioned The pressure ring 12 is embedded in the large hole cavity of the step hole; the cavity of the pressure ring 12 is filled with the output drug 3, which is cyclotrimethylammonium trinitrate, also known as RDX, which has high energy , the advantages of high density, the charging method of the output medicine 3 is loose packing in the natural state or pressure packing; the above-mentioned drug blocking piece 13 is arranged at the large hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com