System adopting mobile project robot to drill holes

A robot and engineering technology, applied in the automatic control system of drilling, drilling equipment, earthwork drilling, etc., can solve the problems of insufficient air circulation, poor working environment, easy fatigue of operators, etc. The effect of reducing the number of required personnel and reducing the impact of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

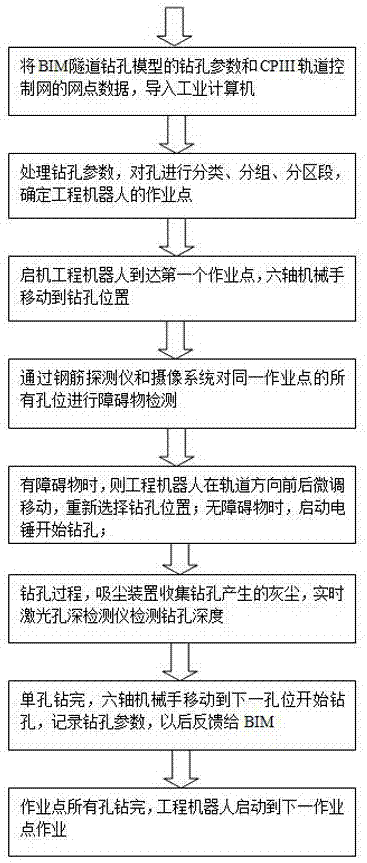

Method used

Image

Examples

Embodiment example 1

[0030] Implementation Case 1: Reference Figure 1 to Figure 3 , a system for tunnel drilling using a mobile engineering robot, including a BIM tunnel drilling model, a CPIII rail control network, and an engineering robot 1;

[0031] Among them, the full English name of BIM is Building Information Modeling. The domestically consistent Chinese translation is Building Information Modeling. Building Information Modeling is based on various relevant information data of construction projects to establish a three-dimensional building model. Through digital information simulation Simulate the real information that buildings have. It has eight characteristics of information completeness, information relevance, information consistency, visualization, coordination, simulation, optimization and graphing.

[0032] BIM tunnel drilling model: design the position of each hole, and export the hole parameters through the Revit secondary program, the hole parameters include coordinates, hole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com