Detection system and method of prestressed steel strand anchor cable tension force

A technology of prestressed steel strand and detection system, which is applied in the test of basic structure, construction, and basic structure engineering, etc. It can solve the problems of inability to monitor the anchor cable of prestressed steel strand for a long time, rough loss judgment, high cost of large projects, etc. , to achieve the effect of improving rapid monitoring ability, improving stability and reliability, and preventing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

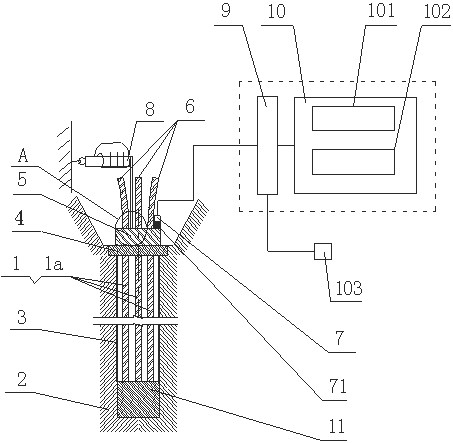

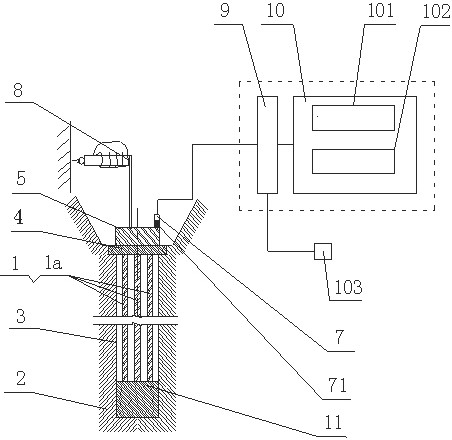

[0042] ①The construction unit conducts construction and lay-out according to the design drawings of the supporting structure, determines the position of the drilling hole 3 of the supporting structure of the rock mass 2, and constructs the drilling hole 3 in the rock mass 2; At the bottom of the borehole 3, an anchor body 11 that is mutually consolidated with the rock mass 2 is formed; one end of the steel strand 1 reaches the bottom of the borehole 3 through the borehole 3, and is anchored with the anchor body 11 at the bottom of the borehole 3; The other end of the wire 1 passes through the pallet 4 and the anchor 5 , the pallet 4 is placed at the hole of the borehole 3 , and anchored in the rock mass 2 , and the anchor 5 is kept in contact with the pallet 4 .

[0043] After the anchor body 11 reaches the anchoring strength, one end of the steel strand 1 passing through the anchor 5 is stretched, and after locking the anchor 5, the steel strand 1 becomes the prestressed steel...

Embodiment B

[0046] ①The process of transforming the steel strand 1 into the prestressed steel strand anchor cable 1a is completed after the construction operation. For example, the anchor 5 of type 5 has a diameter of 15.2 mm of steel strand 1, and the number of 1 steel strand is 5.

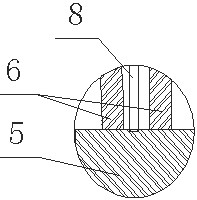

[0047] ②The acceleration sensor 7 is fixedly connected to the end face of the anchor 5 through the magnetic suction seat 71 (or rubber mud or gypsum mud). The vibration direction of the acceleration sensor 7 should be parallel to the length direction of the prestressed steel strand anchor cable 1a, such as figure 1 , 3 As shown, the acceleration sensor 7 is a YD-65 type product, the charge sensitivity is 414.15, the frequency measurement range is 5 to 2000Hz, and there is a matching magnetic suction seat 71 .

[0048] ③The acceleration sensor purchases DH-5922 data collector 9, which is connected to the acceleration sensor 7 by a shielded cable through the matching charge conditioner H5857-1. Connect the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com