Rapid construction method for transverse partitioning and longitudinal sectioning of urban elevated steel box girder bridge

A construction method and technology of steel box girders, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve problems such as constraints, limited lifting weight and size of lifting objects, and difficulty in transporting large-section box girders, and achieve reduction The time of on-site construction, the effect of reducing difficulty and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

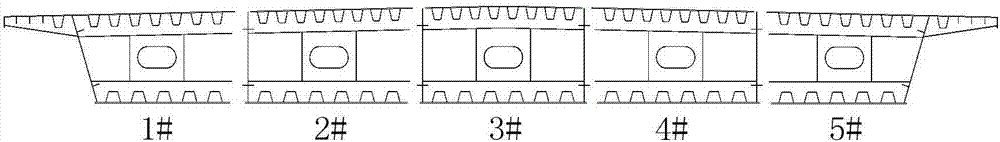

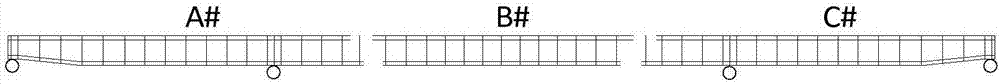

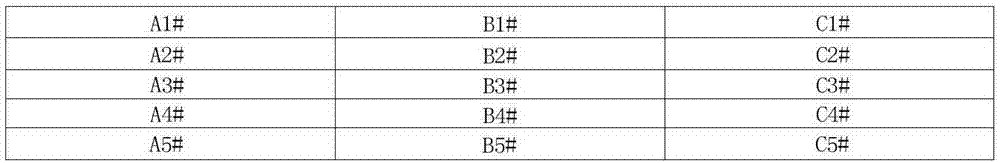

[0020] As shown in Figure 1(A), the steel box girder is divided into horizontal blocks, and each box room is a piece. The same box room cannot lack webs on both sides at the same time, and the box room with the smallest bending stiffness does not lack webs. plate; as shown in Figure 1(B), longitudinally segment the steel box girder, and determine the longitudinal cutting position of the steel box girder according to the lifting capacity of the on-site crane, the layout of the span and the pier position, and use the dislocation of the top and bottom plates for the division , wherein the top plate of the hoisted part is shorter than the bottom plate, and the top plate of the part hoisted later is longer than the bottom plate, so that the part hoisted first can be used as the support of the part hoisted later; The sequence of the factory prefabricated hoisting unit: Figure 2 (A) is the tire frame positioning panel on the floor; Figure 2 (B) is the completion of the tire frame posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com