Full-automatic dye weighing and dissolving equipment

A fully automatic and automatic weighing technology, which is used in the equipment configuration of textile materials, textile materials processing, textiles and papermaking, etc., can solve the problem of large physical injury of workers, chemical material time, water consumption and water temperature and the degree of mixing uniformity is difficult to standardize. , miscasting and other problems, to achieve the effect of improving the utilization rate of workshop space, reducing labor costs, and improving access efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

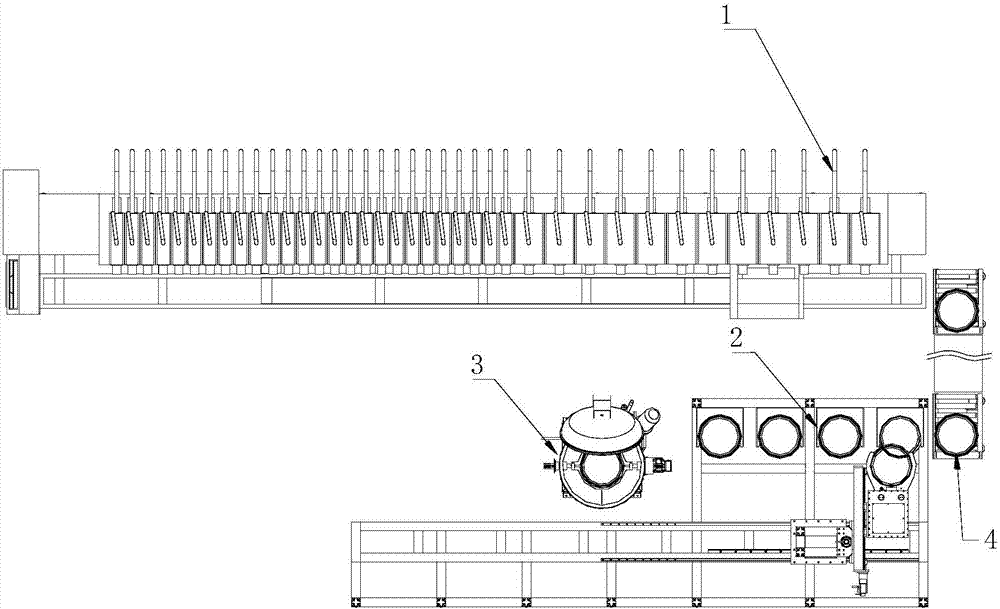

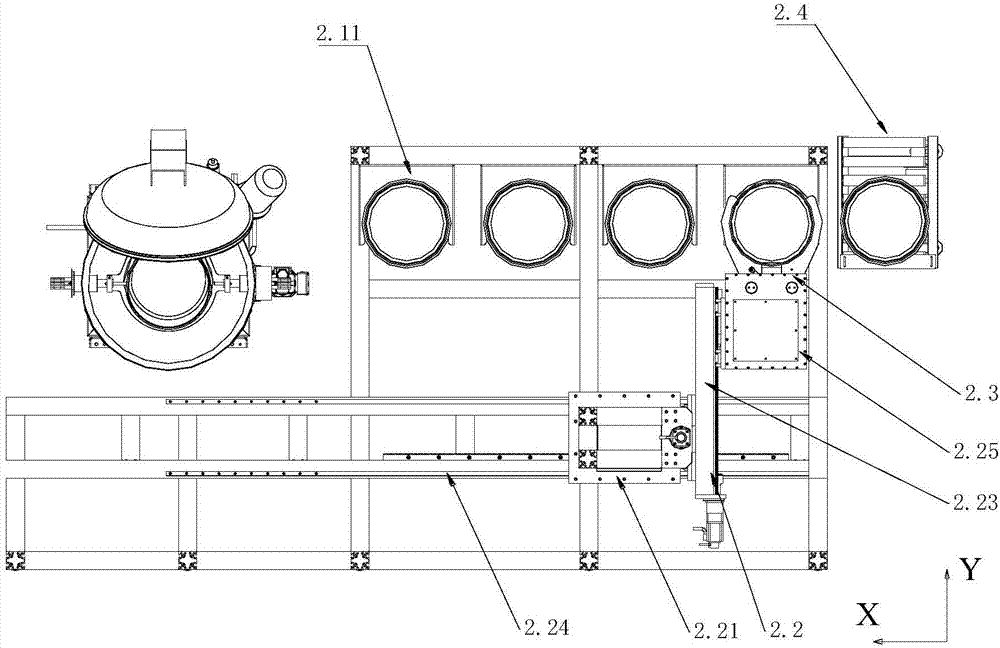

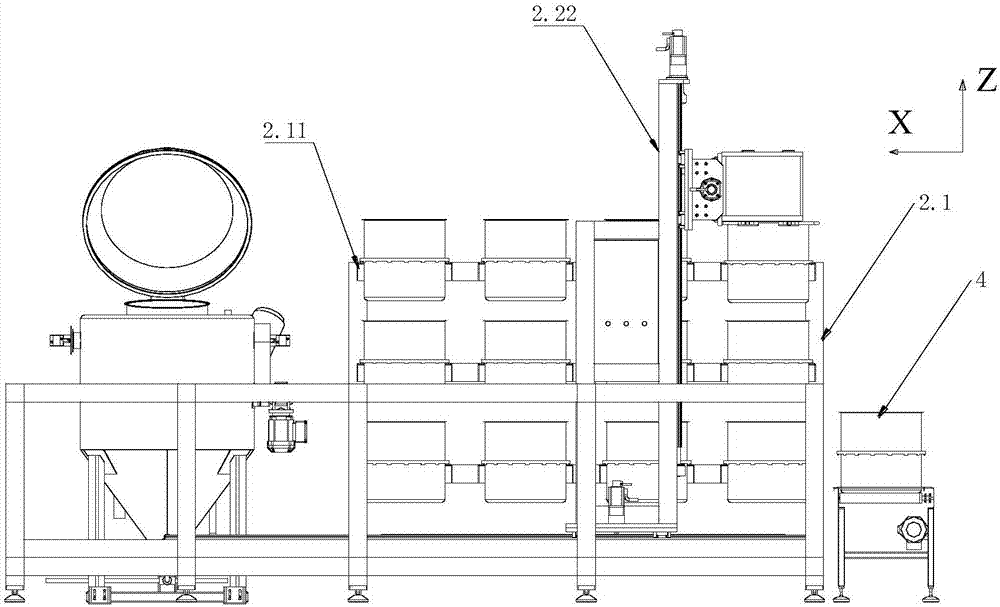

[0046] A kind of automatic dye weighing and chemical material equipment, refer to the attached figure 1 , including powder dye automatic weighing system 1, automatic grasping three-dimensional warehouse 2, dye chemical material device 3, and special dye bucket 4;

[0047] The powdery dye automatic weighing system 1 adopts the "powdery dye automatic weighing system" of patent No. CN2013102181007 to realize the weighing and batching of powdery dye, and the powdery dye automatic weighing system is used to move the material receiving trolley side. The material platform is connected to the feeding platform of the automatic grabbing three-dimensional warehouse through a conveyor (roller conveyor), and the dye barrels filled with dyes are transported to the feeding port of the automatic grabbing three-dimensional warehouse through the discharging platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com