3A molecular sieve and processing technology thereof

A processing technology and molecular sieve technology, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of unfavorable industrialized production and high production cost, achieve abundant reserves, simple method, and improve ion exchange rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

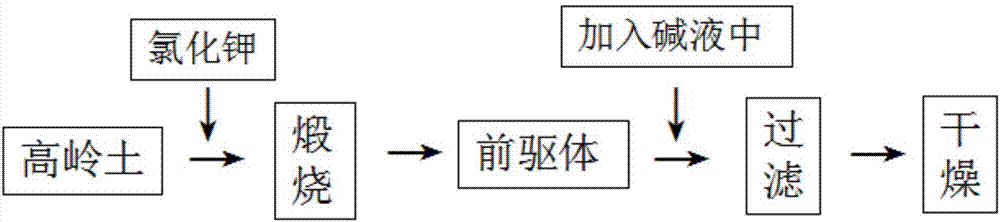

Method used

Image

Examples

Embodiment 1

[0022] Mix 10 parts of kaolin with 4 parts of KCl, and calcinate at 700°C for 5 hours to obtain a precursor mixture; take a clean beaker and add 3g KOH and 10g NaOH, add 100ml deionized water to the beaker, and after it is completely dissolved, weigh the precursor mixture 4Og, added to the beaker. After mixing evenly, the mixture was transferred to an Erlenmeyer flask, and the Erlenmeyer flask was placed in a water bath for heating reaction. After reacting at 90°C for 6 hours, the reaction product was taken out, and the 3A molecular sieve product was obtained after suction filtration and drying.

Embodiment 2

[0023] Example 2: Mix 10 parts of kaolin with 4 parts of KCl, and calcinate at 700°C for 4 hours to obtain a precursor mixture; take a clean beaker and add 2.4g KOH and 10g NaOH, and add 100ml of deionized water to the beaker, after completely dissolving , weighed 37g of the precursor mixture, and added it to the beaker. After mixing evenly, the mixture was transferred to an Erlenmeyer flask, and the Erlenmeyer flask was placed in a water bath for heating reaction. After reacting at 85°C for 8 hours, the reaction product was taken out, and the 3A molecular sieve product was obtained after suction filtration and drying.

Embodiment 3

[0024] Example 3: Mix 10 parts of kaolin with 4 parts of KCl, and calcinate at 600°C for 4 hours to obtain a precursor mixture; take a clean beaker and add 3g KOH and 10g NaOH, and add 100ml deionized water to the beaker. After completely dissolving, Weigh 42g of the precursor mixture and add it into the beaker. After mixing evenly, the mixture was transferred to an Erlenmeyer flask, and the Erlenmeyer flask was placed in a water bath for heating reaction. After reacting at 85°C for 6.5 hours, the reaction product was taken out, and the 3A molecular sieve product was obtained after suction filtration and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com