A tower crane dismantling structure and method for high-rise installation

A high-rise and tower crane technology, applied in the direction of cranes, etc., can solve the problems of heavy weight, bulky, time-consuming and labor-intensive, and achieve the effects of saving installation costs and operating costs, strong installation flexibility, and simple fixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to express the present invention more clearly, the present invention will be further described below with reference to the accompanying drawings.

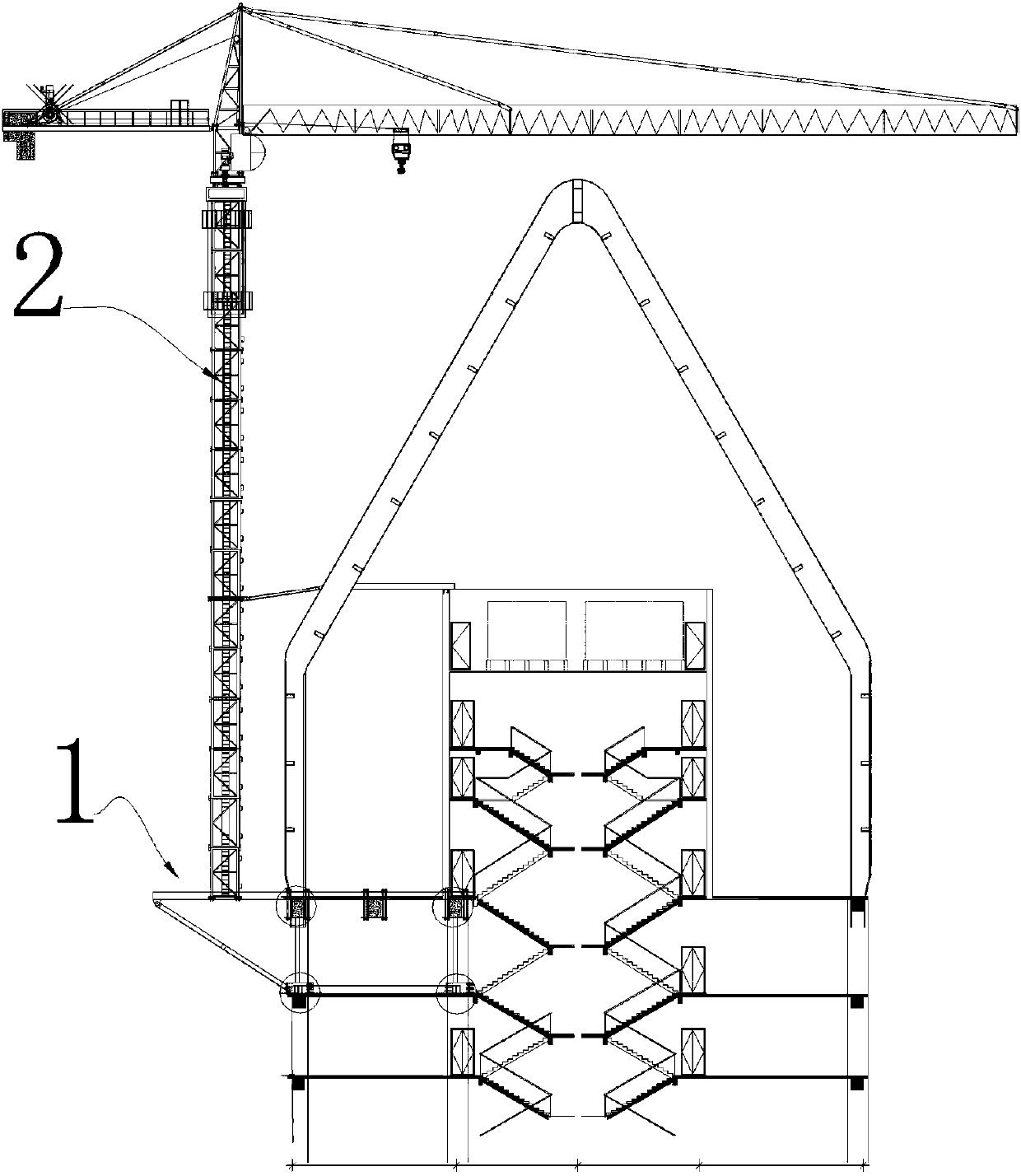

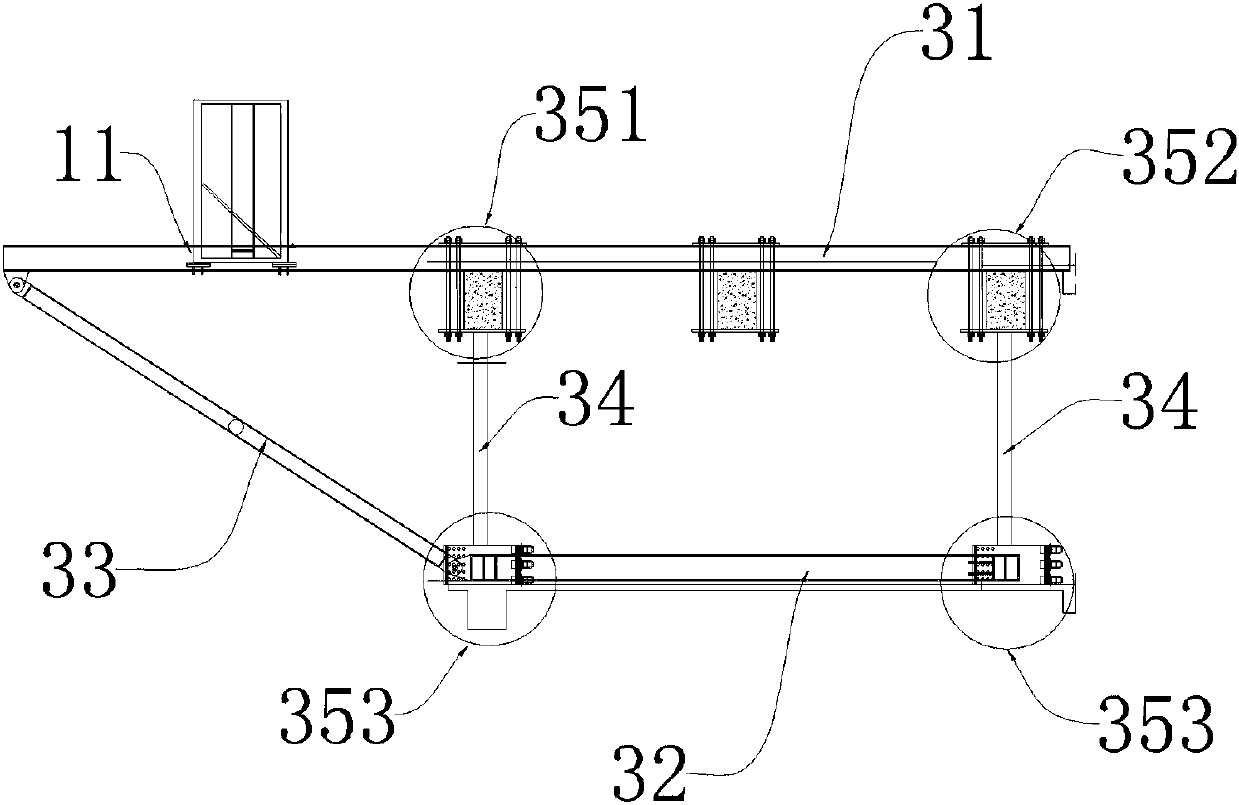

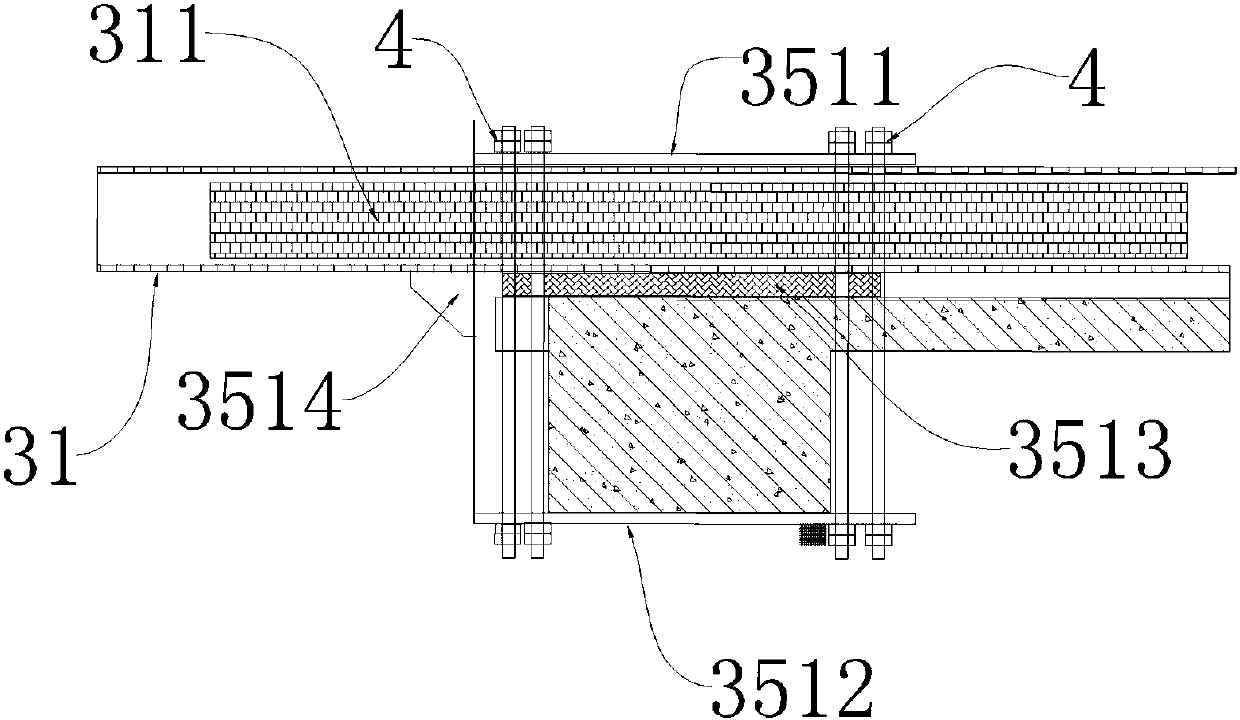

[0025] See Figure 1-Figure 2 The invention discloses a disassembly structure for a tower crane installed in a high-rise. The basic steel beam of the tower crane is installed between the high-rise floors, the roof crane is also installed between the high-rise floors, and the basic structure of the roof crane adopts a cantilevered steel beam structure. The steel cantilever beams include upper box beams 31, lower box beams 32, diagonal struts 33, H-shaped steel 34 and fastening devices. The upper box beams 31 extend from the core of the building to the edge of the building to the outside of the building wall , The lower box beam 32 extends from the core position of the building to the edge of the building, the upper box beam 31 and the edge position of the building and the lower box beam 32 and the edge position of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com