Paper battery coating device

A technology of coating device and paper battery, which is applied to devices for coating liquid on the surface, coating, surface pretreatment, etc. Problems such as low membrane control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0013] The technical scheme of concrete implementation of the present invention is:

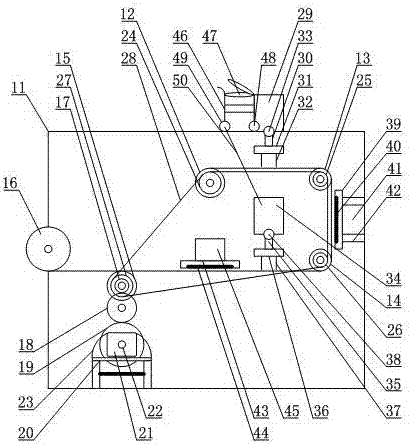

[0014] Such as figure 1 Shown, a kind of paper battery film coating device comprises frame 11, is provided with unwinding drum 12, the first pulling drum 13, the second pulling drum 14, driving drum 15 and winding drum 16 on the frame 11, unwinding Cylinder 12, the first traction cylinder 13, the second traction cylinder 14, transmission cylinder 15 and take-up cylinder 16 are connected successively; The outer end of transmission cylinder 15 is provided with driven gear 17, and frame 11 is provided with transmission gear 18, machine The frame 11 is provided with a bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com