Chemical liquid plasma treatment method and equipment

A plasma and chemical liquid technology, applied in the field of ion treatment, can solve the problems of high investment cost, low reaction efficiency and high thermal conversion, and achieve the effects of improving reaction efficiency, increasing reaction specific surface area and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

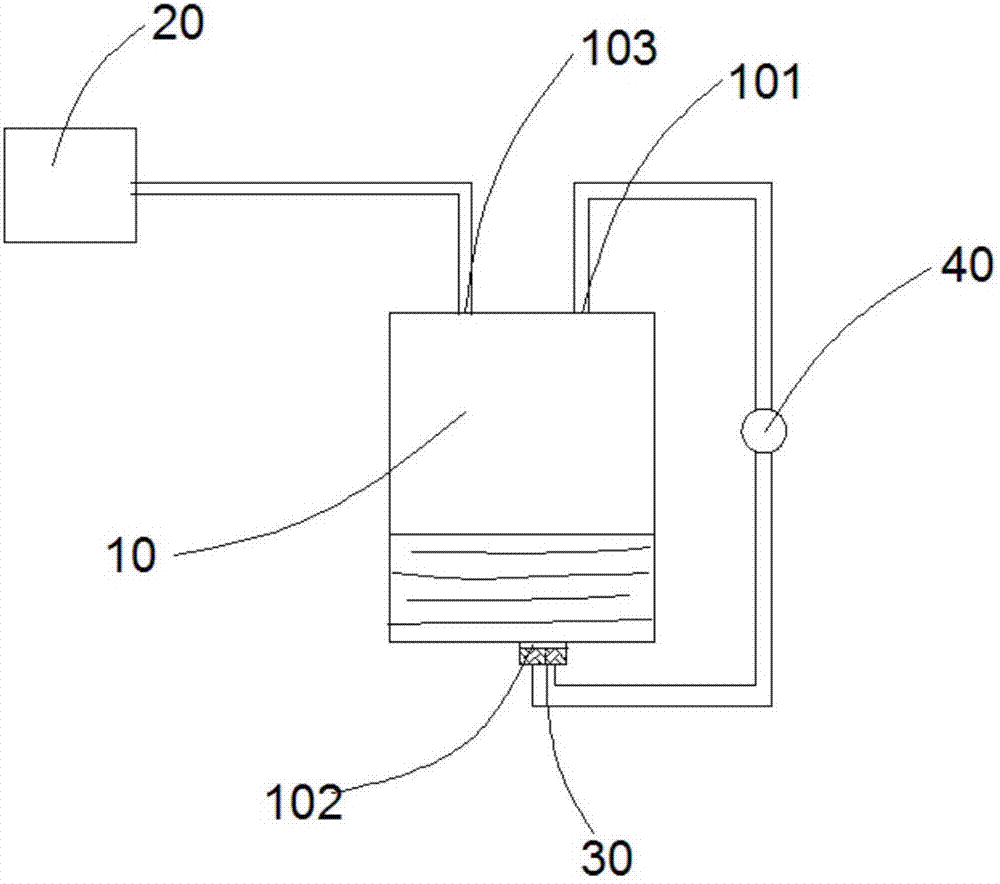

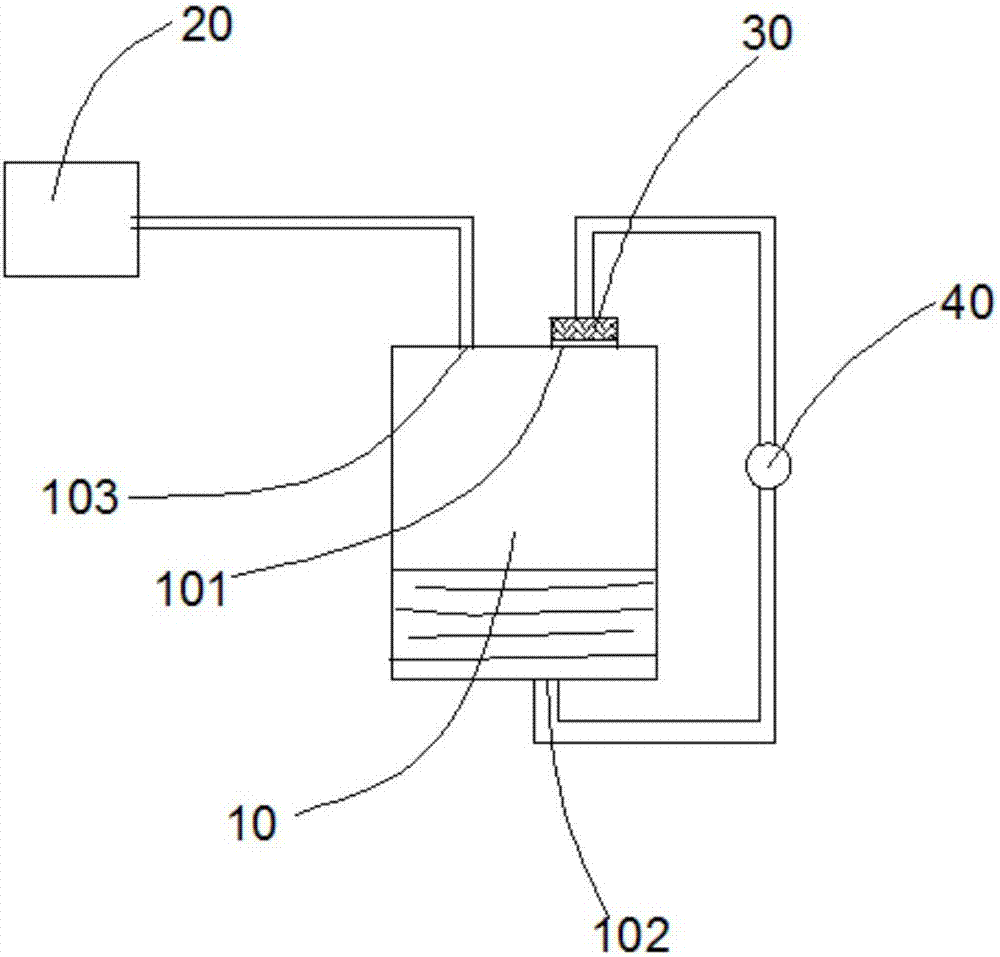

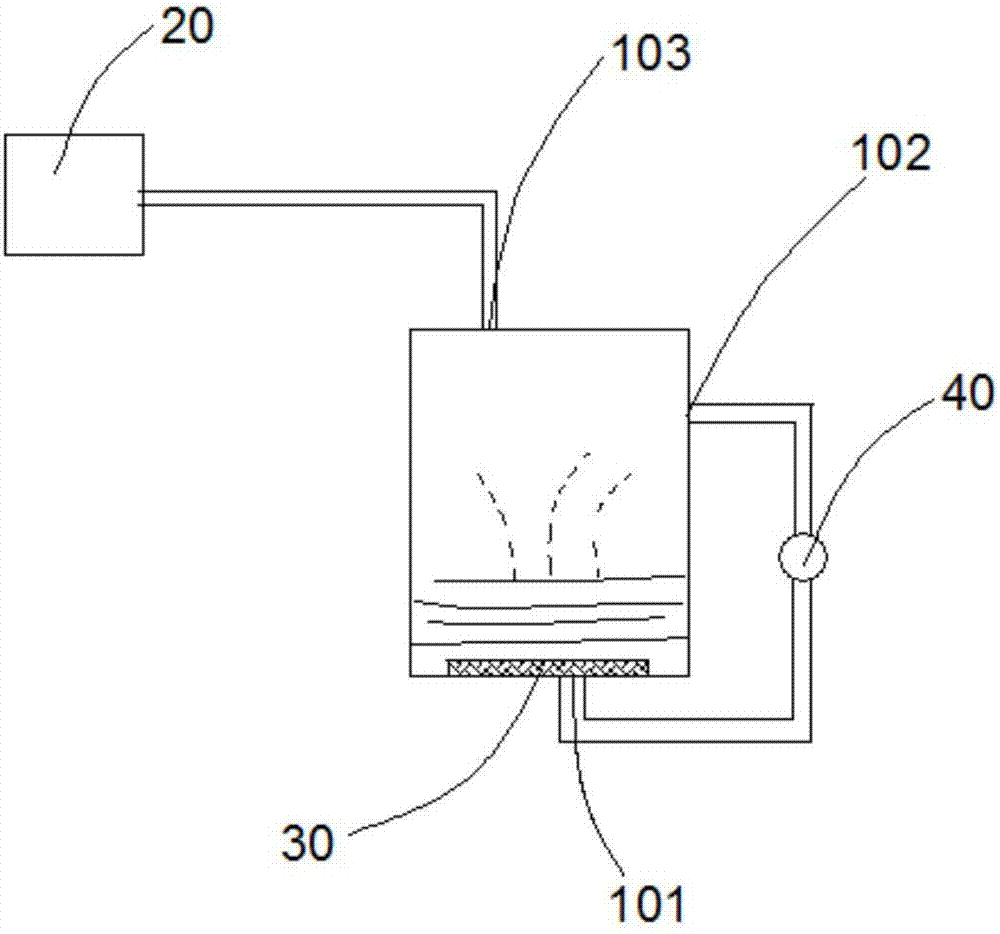

[0054] As a preferred embodiment of the present invention, comprising the following steps:

[0055] Atomization treatment: First, part of the liquid to be treated is atomized to obtain droplet particles;

[0056] Reaction with plasma: the mist particles are mixed with the plasma to form a gas-liquid mixture, and the product obtained after the plasma in the gas-liquid mixture reacts with the mist of the liquid to be treated is dissolved in the remaining liquid to be treated;

[0057] The steps of atomization and reaction with plasma are repeated until all the liquid to be treated is treated.

[0058] Repetition can make the reaction between the liquid to be treated and the plasma more sufficient, and the circulation can be completed in the same container, which is beneficial to save equipment cost.

[0059] As a preferred embodiment of the present invention, the size of the droplet particles obtained after the liquid to be treated is atomized is 0.2-200 microns.

[0060] As a...

Embodiment 1

[0066] A plasma treatment method for chemical liquid, comprising the following steps:

[0067] Step a): atomize part of the liquid to be treated first to obtain liquid droplet particles with a size of 0.2-30 microns;

[0068] Step b): Mixing the droplet particles with plasma (plasma generated by the excitation of air in the plasma generator) to form a gas-liquid mixture, the plasma in the gas-liquid mixture reacts with the liquid to be treated in the droplet particles to obtain The product is dissolved in the remaining liquid to be treated;

[0069] Step a) and step b) are repeated until all the liquid to be treated is completely treated, thereby realizing the treatment of the liquid.

[0070] In this embodiment, the liquid to be treated is sewage. The plasma generated in the above-mentioned plasma generator reacts with the organic matter in the mist particles of the sewage to generate harmless substances such as water or carbon dioxide, so as to achieve the purpose of remov...

Embodiment 2

[0072] A plasma treatment method for chemical liquid, comprising the following steps:

[0073] Step a): atomize part of the liquid to be treated first to obtain liquid droplet particles with a size of 30-110 microns;

[0074] Step b): Mixing the droplet particles with plasma (plasma generated by the excitation of air in the plasma generator) to form a gas-liquid mixture, the plasma in the gas-liquid mixture reacts with the liquid to be treated in the droplet particles to obtain The product is dissolved in the remaining liquid to be treated;

[0075] Step a) and step b) are repeated until all the liquid to be treated is completely treated, thereby realizing the treatment of the liquid.

[0076] In this embodiment, the liquid to be treated is sewage. The plasma generated in the above-mentioned plasma generator reacts with the organic matter in the mist particles of the sewage to generate harmless substances such as water or carbon dioxide, so as to achieve the purpose of remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com