Quick uniform mixing device for gas

A uniform mixing and fast technology, applied in the field of machinery, can solve the problems of increasing production and processing costs, increasing equipment size, and excessive local reactions, and achieving the effect of improving mixing efficiency and speeding up mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the scope of protection.

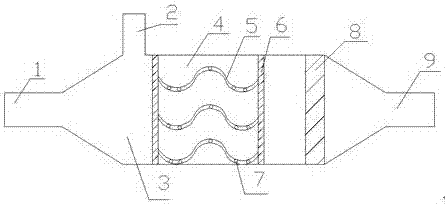

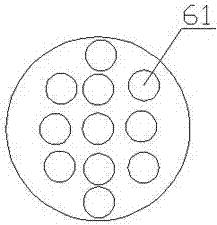

[0013] A gas rapid homogeneous mixer, comprising an air inlet, a mixing area and an air outlet 9, the air inlet has a first air inlet 1 and a second air inlet 2, and the mixing area includes a premixing area 3 and The main mixing zone 4, the premixing zone 3 communicates with two air inlets, the two ends of the main mixing zone 4 are provided with two support plates 6, and the support plate 6 is provided with a plurality of through holes 61, the The two support plates 6 are connected with some ventilation pipes 5, the ventilation pipes 5 are provided with some air holes 7, the ventilation pipes 5 are S-shaped curve pipes, and fillers are arranged after the main mixing zone 4 before the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com