Distributed state feedback control method for liquid level of four-tank water tank

A state feedback and control method technology, which is applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve problems such as poor flexibility, low safety, and low reliability, and achieve smooth tracking process and anti-coupling The effect of strong performance and excellent control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

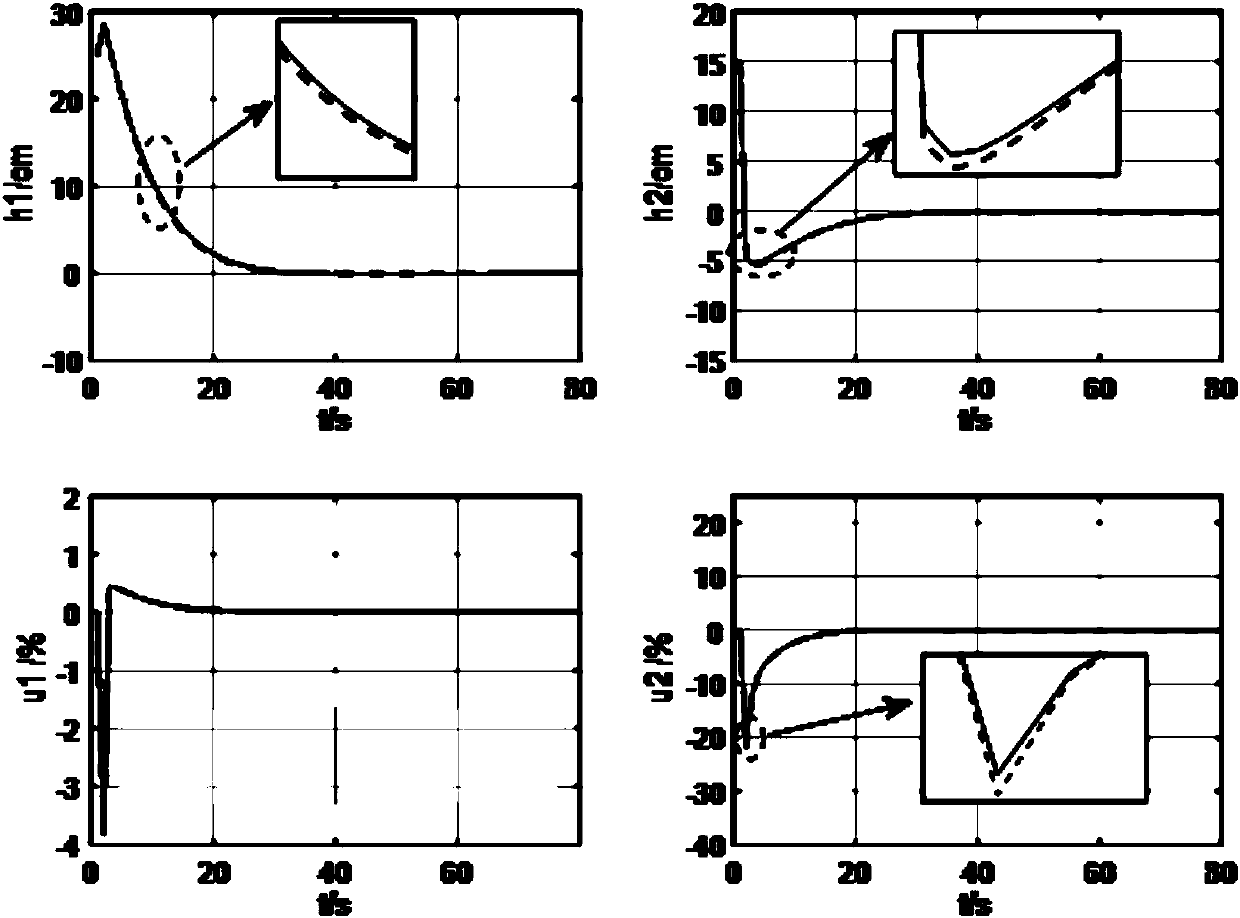

[0039] In the following, the present invention will be described in detail by taking the liquid level process control of a four-capacity water tank as an example in conjunction with the accompanying drawings.

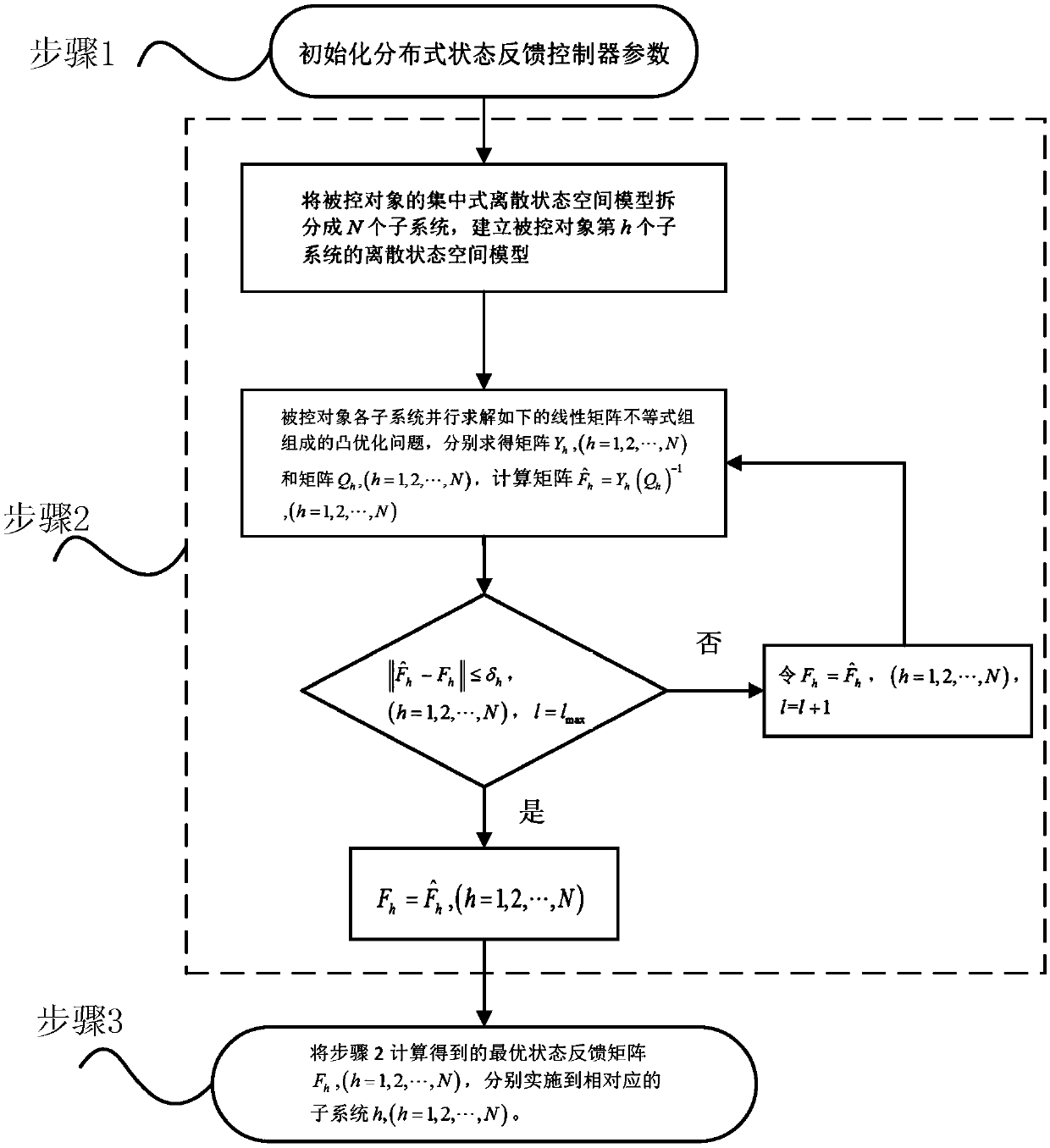

[0040] Such as figure 1 Shown is the flow chart of the distributed state feedback control method of the present invention, wherein, the continuous time process model of the four-capacity water tank is as follows:

[0041]

[0042]

[0043]

[0044]

[0045]

[0046]

[0047] Among them, h i Indicates the liquid level of tank i, Indicates the liquid level derivative of tank i, v i Indicates the speed of pump i, Indicates the rotational speed derivative of pump i, u i Indicates the speed control signal of water pump i, a i Indicates the outlet cross-sectional area of tank i, A i Indicates the cross-sectional area of the water tank i, g indicates the acceleration of gravity, γi Indicates the split ratio of water pump i sent to the high water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com