Solid engine adhesion interface loaded state monitoring device

A solid-state engine and detection device technology, applied in the direction of internal combustion engine testing, etc., to achieve the effects of easy installation, full life cycle measurability, high accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1. Solid engine and its monitoring and detection system

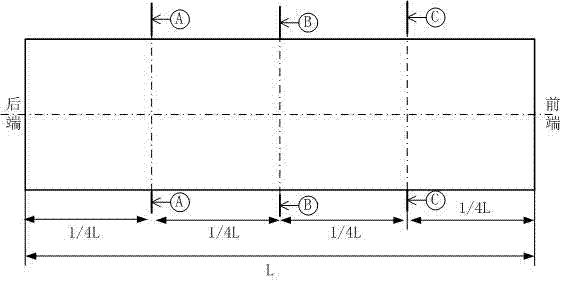

[0029] The structure of the solid engine is mainly composed of an ignition device, a combustion chamber, and a nozzle. The combustion chamber is the core component of the solid engine, and the bonding interfaces of the engine are the weak parts of the combustion chamber. Therefore, the monitoring of the health status of the bonding interface is an important part of the health monitoring of the engine structure. According to the causes, characteristics and failure mode analysis results of the debonding of the engine bonding interface, the target quantity of the solid engine structure health monitoring is determined to be the stress and temperature of the grain bonding interface.

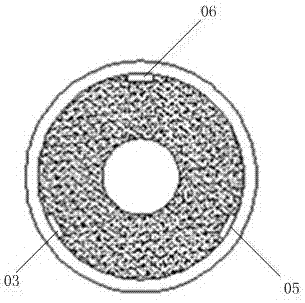

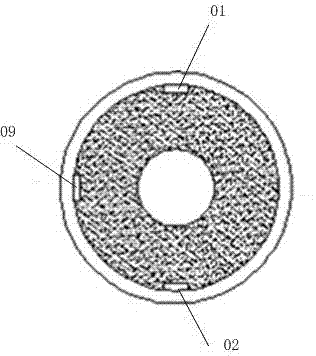

[0030] The solid engine structural health monitoring system is mainly composed of hardware-solid engine bonding interface loading state monitoring device and software. The hardware part includes the sensor network and the corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com