Pressure-induction speed increasing control method, high-static-pressure fan system and range hood

A control method and high static pressure technology are applied in the fields of range hoods, pressure induction speed increasing control methods and high static pressure fan systems, which can solve the problem that the range hood cannot be adjusted in real time, the smoke exhaust effect cannot be obtained, and the smoke exhaust effect cannot be affected. and other problems, to achieve the effect of good smoke exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described in detail below:

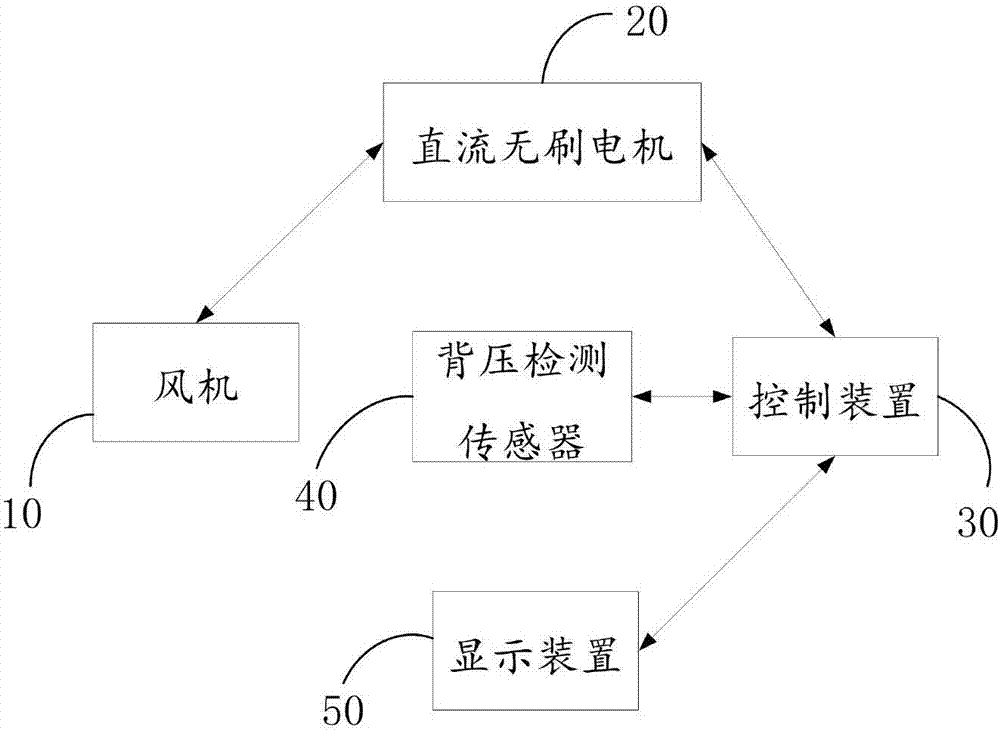

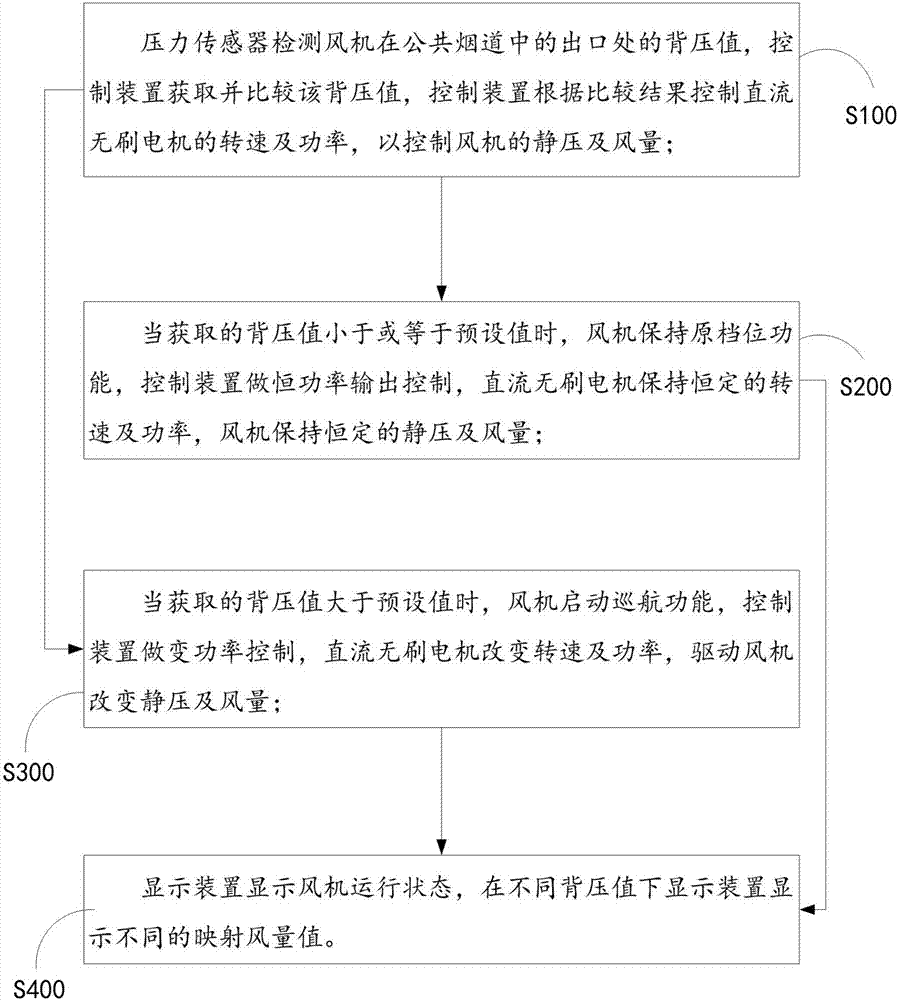

[0040] Such as figure 1 As shown, the present invention proposes a high static pressure fan system, including a fan 10, a DC brushless motor 20 connected to the fan 10, and a control device 30 connected to the DC brushless motor 20, which are arranged in a public flue And a back pressure detection sensor 40 connected with the control device 30 , and a display device 50 connected with the control device 30 . Moreover, the fan 10 can be used to output a certain air volume and static pressure, the output air volume can be adjusted according to the size of the oil fume in the kitchen, and the output static pressure can be adjusted according to the back pressure of the fan; and the brushless DC motor 20 can be used The fan 10 is driven to output different air volumes and static pressures according to different speeds and powers; the control device 30 can be used to control and adjust the speed and power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com